Pressure-maintaining push-pull cylinder and clamping device using the same

A push-pull cylinder and oil cylinder technology, applied in the field of fixtures, can solve the problems of low nitrogen density, high manufacturing cost, increased nitrogen spring pressure, etc., and achieve the effects of convenient processing, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

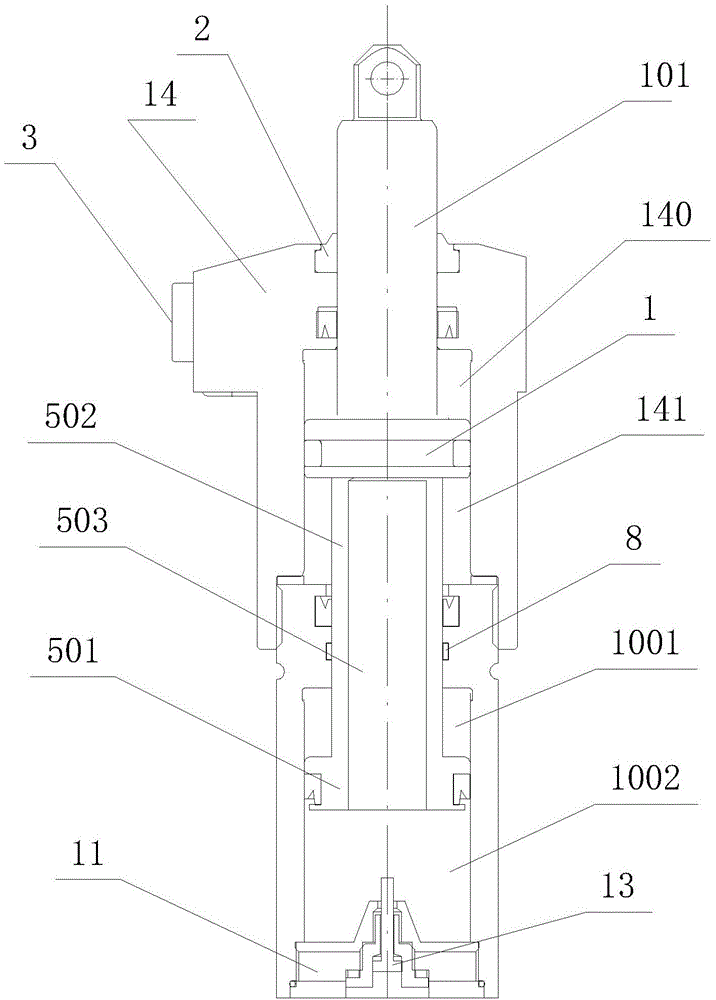

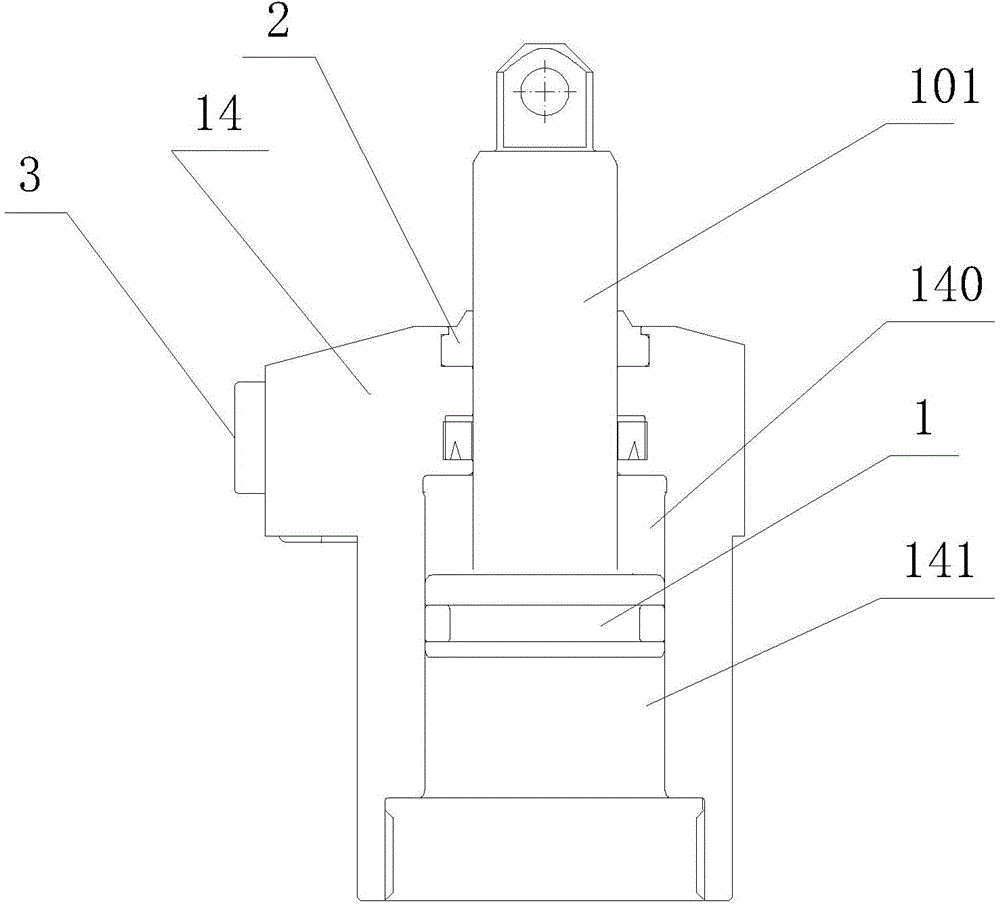

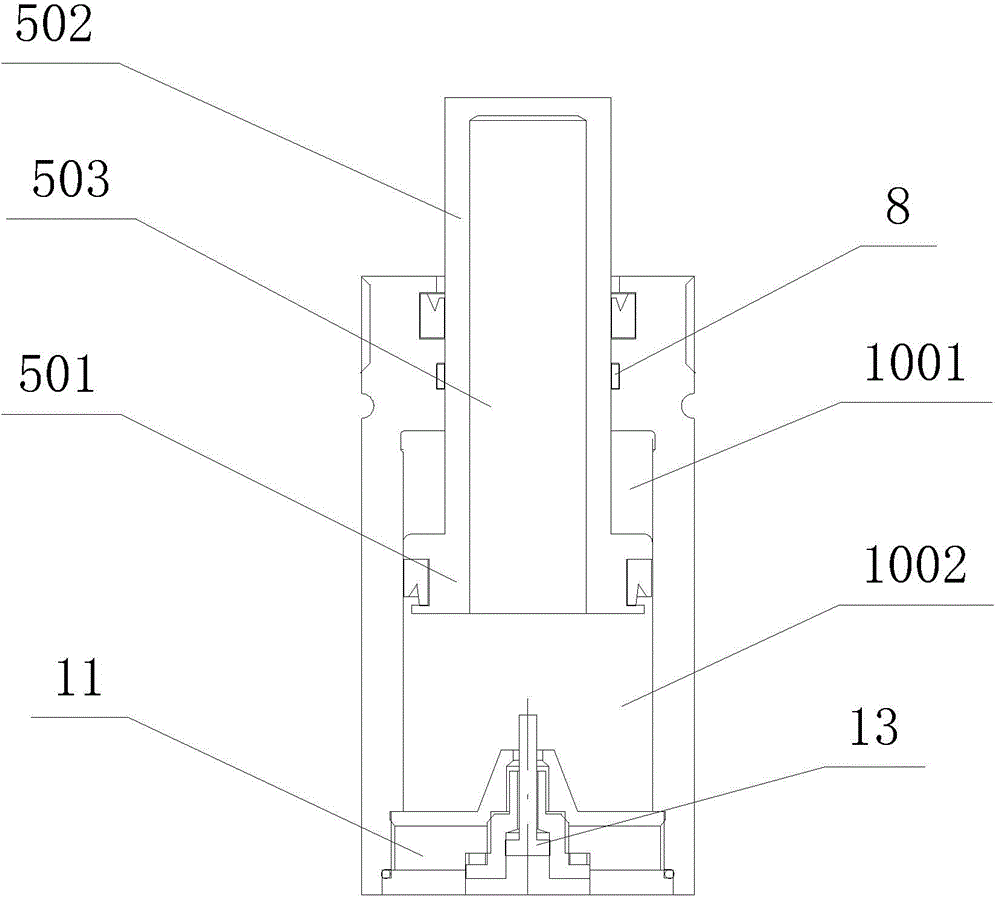

[0025] The invention provides a pressure-maintaining push-pull cylinder, refer to figure 1 , its invention point is, comprise oil cylinder and the nitrogen cylinder that is fixed on the end of oil cylinder, offer the oil inlet hole that communicates with the rod chamber (one end that has rod) of oil cylinder at the side wall of oil cylinder, the piston rod of nitrogen cylinder and oil cylinder The rodless chamber (one end of the rodless) is connected, and an air inlet connected with the rodless chamber of the nitrogen cylinder is provided on the nitrogen cylinder, and a check valve is arranged on the air inlet, so that a high pressure is formed in the nitrogen cylinder. The cavity is sealed and has a compression function. The piston rod of the nitrogen cylinder can extend into the rodless cavity of the oil cylinder, and the extension and retraction of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap