A high-yield cultivation device with an annual output of 3‑4 crops of low-carbon energy raw materials

A cultivation device and energy technology, applied in the field of energy processing raw material production equipment, can solve problems such as low annual output of corn planting, and achieve the effects of small omissions, increased yield, and comprehensive coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

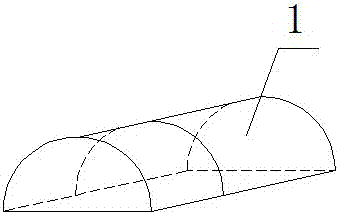

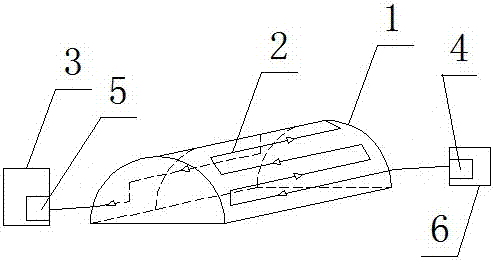

[0033] In order to overcome the defects of the existing technology, this embodiment provides as figure 1 , 2 , 4, 6, 7, 8, a high-yield cultivation device with an annual output of 3-4 crops of corn, including a solar heating greenhouse 1 and its skeleton, and the solar heating greenhouse 1 is equipped with space heating equipment and soil heating equipment And multi-functional auxiliary equipment; the direct row space heating equipment is composed of the first heating pipe 2, circulation pump 1 4, circulation pump 2 5, waste water pool 3 and natural hot water pool 6, and the heating pipe 2 is hoisted Below the framework of the sunlight heating greenhouse 1, the circulation pump-4 for pumping water from the natural hot water pool 6 is installed at one end of the heating and heating pipe 2 leading into the sunlight heating greenhouse 1, and the heating and heating pipe 2 leads out of the sunlight heating One end of warm greenhouse 1 is equipped with the circulating pump 2 5 tha...

Embodiment 2

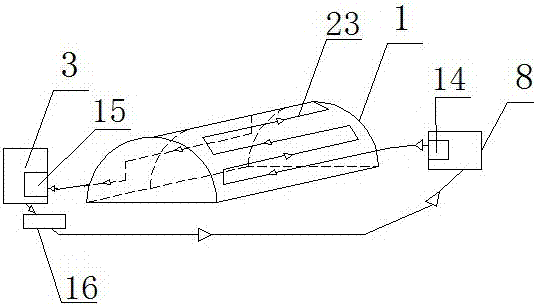

[0046] On the basis of embodiment one, in this embodiment such as image 3 The space heating equipment shown uses hot water that is artificially processed. When the temperature applied to the greenhouse space does not reach the appropriate temperature according to the above method, the waste water in the third heating pipe 23 of the greenhouse space is pumped into the waste water pool 3 through the circulation pump seven 15, and then the waste water is drawn from the waste water pool 3 by the circulation pump eight 16. In the waste water pool 3, the waste hot water is sent back to the artificial hot water pool 8 through the third heating pipe 23, and the hot water is reheated to the optimum temperature, and then pumped into the first part of the sunlight heating greenhouse 1 by the circulation pump 6 14. The space in the three heating and heating pipes 23 continues to heat up. When the water temperature is unqualified, the circulation pump 7 15 and the circulation pump 8 16 d...

Embodiment 3

[0048] On the basis of Embodiment 1, in this embodiment such as Figure 5 The hot water of the soil heating equipment in the shown solar heating greenhouse 1 is artificially processed hot water, then when the temperature of the hot water used for the fourth heating and heating pipe 24 is not suitable for heating, the waste water is circulated by the circulation pump three times. 18 is pumped into the waste water pool 3, and the waste hot water in the waste water pool 3 is pumped into the artificial hot water pool 8 through the fourth heating heating pipe 24 by the circulating pump 107. After the reheating is qualified, it is sent into the greenhouse. The fourth heating pipe 24 continues to heat the soil. When the hot water temperature is not suitable, it is sent back to the artificial hot water pool 8 by the above method to continue heating into hot water at a suitable temperature, and is sent back to the sunlight heating greenhouse 1 again. Continue to heat the soil in the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com