Preparation and application of graphene oxide-bonded silica gel composite

A technology of bonding silica gel and composite materials, which is applied in applications, tobacco, e-liquid filter elements, etc., and can solve problems such as the influence of cigarette flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

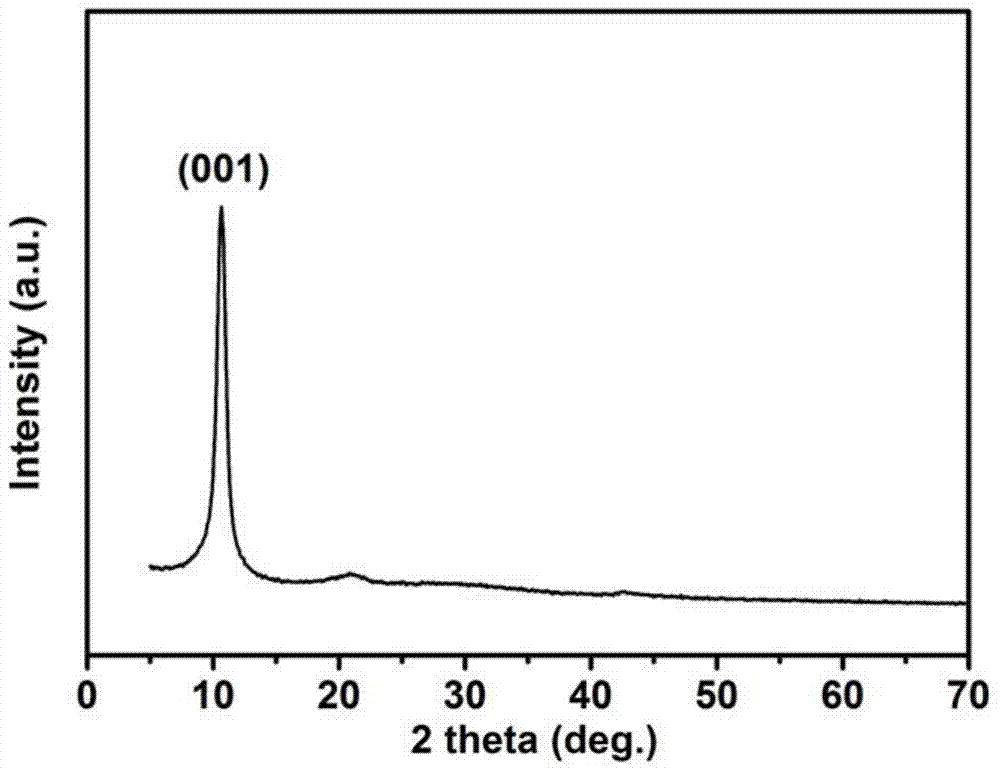

[0092] 1. Preparation of GO

[0093] 10g graphite powder, 5gNaNO 3 Add 230ml of concentrated sulfuric acid into a large beaker with a volume of 2L, and stir at 0°C for 30 minutes to carry out pre-oxidation treatment. After pre-oxidation treatment, 30g of KMnO 4 This was added slowly, and the mixture was stirred at room temperature until it became a brown slurry. After stirring for 120 minutes, 500ml of deionized water was slowly added to the brown slurry, and the reaction temperature rose sharply at this time, and the stirring was continued for 120 minutes. Then add 1L of warm water and 100ml of 30% H 2 o 2 , stir evenly, centrifuge and filter. The sample obtained after filtration was washed twice with dilute hydrochloric acid, then twice with deionized water, and dried in a vacuum oven at room temperature to finally obtain GO powder.

[0094] 2. Preparation of GO / silica gel composites

[0095] Take 200mg of GO powder and disperse it into 500ml of N,N dimethylformamide....

Embodiment 2

[0099] 1. Preparation of GO

[0100] 10g graphite powder, 4.5gNaNO 3 and 210ml of concentrated sulfuric acid were added into a large beaker with a volume of 2L, and stirred at 0°C for 20 minutes for pre-oxidation treatment. After pre-oxidation treatment, 28g of KMnO 4 This was added slowly, and the mixture was stirred at room temperature until it became a brown slurry. After stirring for 110 minutes, 480ml of deionized water was slowly added to the brown slurry, and the reaction temperature rose sharply at this time, and the stirring was continued for 110 minutes. Then add 950ml of warm water and 95ml of 30% H 2 o 2 , stir evenly, centrifuge and filter. The sample obtained after filtration was washed twice with dilute hydrochloric acid, then twice with deionized water, and dried in a vacuum oven at room temperature to finally obtain GO powder.

[0101] 2. Preparation of GO / silica gel composites

[0102] Disperse 200mg of GO powder into 480ml of N,N dimethylformamide. Af...

Embodiment 3

[0106] 1. Preparation of GO

[0107] 10g graphite powder, 5.5gNaNO 3 Add 250ml of concentrated sulfuric acid into a large beaker with a volume of 2L, and stir at 5°C for 40 minutes to carry out pre-oxidation treatment. After pre-oxidation treatment, 32g of KMnO 4 This was added slowly, and the mixture was stirred at room temperature until it became a brown slurry. After stirring for 130 minutes, 520ml of deionized water was slowly added to the brown slurry, and the reaction temperature rose sharply at this time, and stirring was continued for 130 minutes. Then add 1L of warm water and 105ml of 30% H 2 o 2 , stir evenly, centrifuge and filter. The sample obtained after filtration was washed twice with dilute hydrochloric acid, then twice with deionized water, and dried in a vacuum oven at room temperature to finally obtain GO powder.

[0108] 2. Preparation of GO / silica gel composites

[0109] Take 200mg of GO powder and disperse it into 520ml of N,N dimethylformamide. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com