The synchronous control system between the push claw device and the center box device and the automatic machine in the capsule machine

A technology of synchronous control and automaton, which is applied in the fields of capsule delivery, drug delivery, and pharmaceutical formulations. It can solve problems such as higher and higher requirements for equipment automation, connection failures of operating units, and increased maintenance workload. Improve the effect of asynchronous and impact-prone failures, reduce maintenance costs, and reduce mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

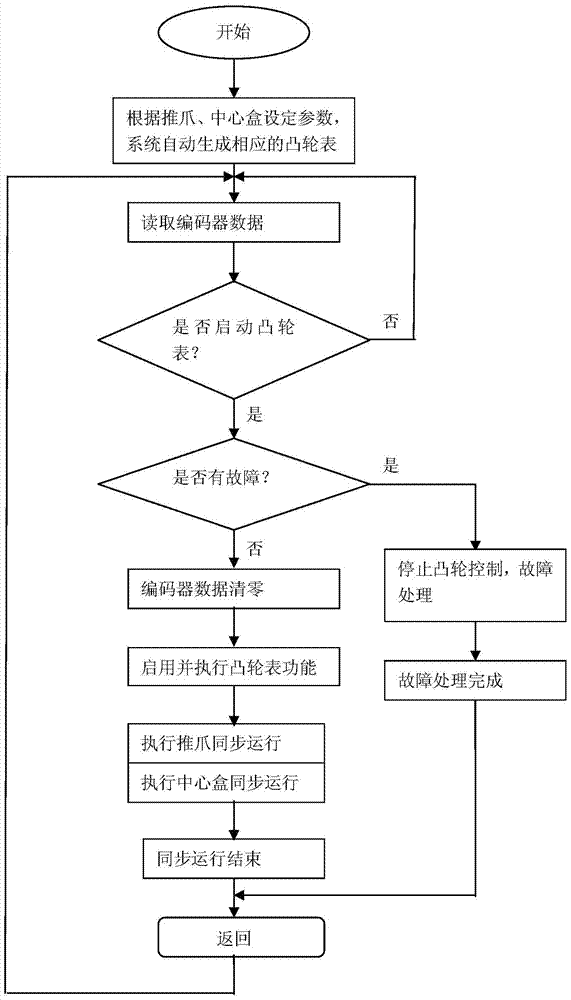

[0046] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

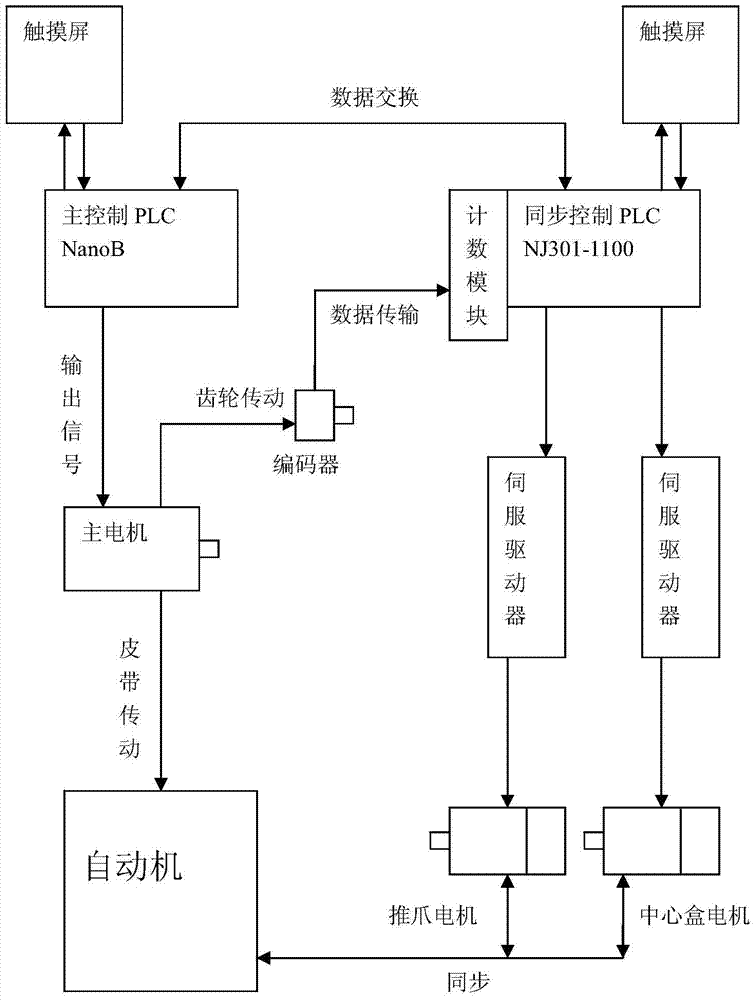

[0047] Such as figure 1 As shown, the synchronous control system between the push claw device and the center box device and the automatic machine in the capsule machine of the present invention has a main control unit and a synchronous control unit, wherein the output terminal of the main control unit is connected with a main motor control circuit, and the main motor passes through the transmission device Drive the automatic machine to run; the synchronous control unit collects the speed data of the main motor through the encoder, the synchronous control unit controls the claw motor and the center box motor respectively through two servo drivers, and the main control unit communicates with the synchronous control unit.

[0048] The main motor is connected to the reduction box, one side of the output shaft of the reduction box pulls the mechanical au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com