Waste gas purification device

An exhaust gas purification device and exhaust gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of heavy cleaning and maintenance management workload, high cost, insufficient contact and absorption of exhaust gas and washing liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

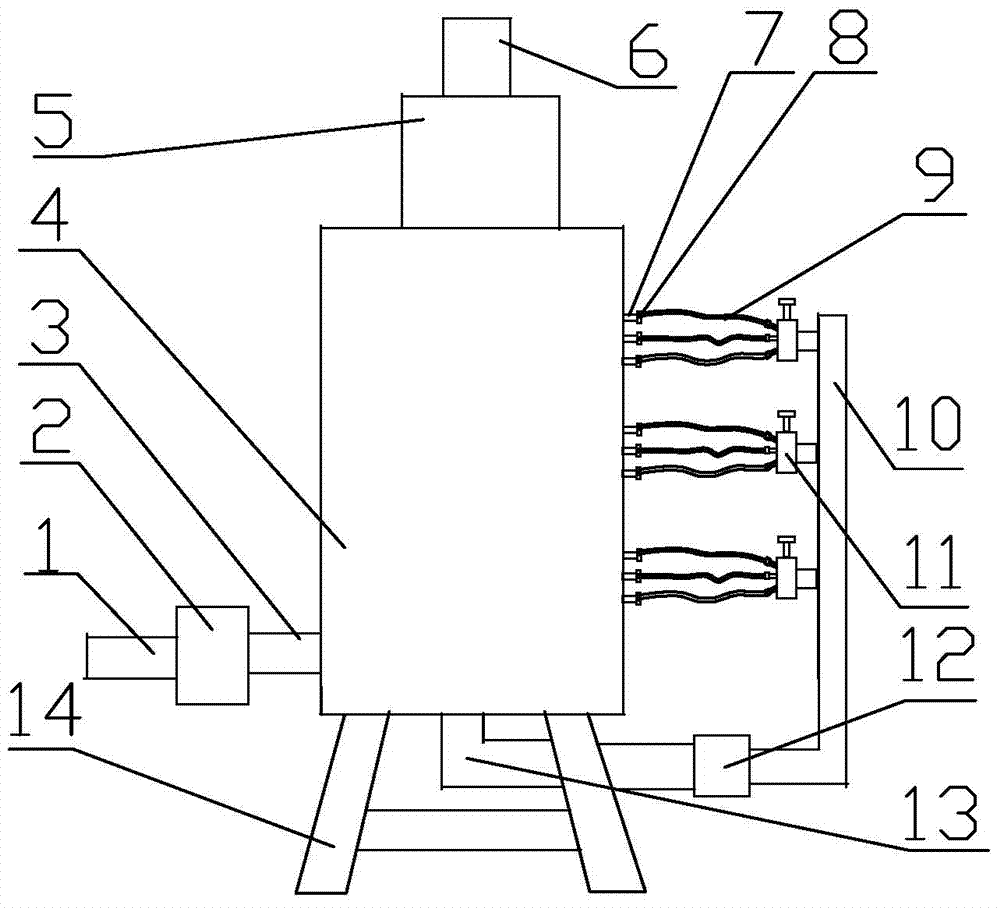

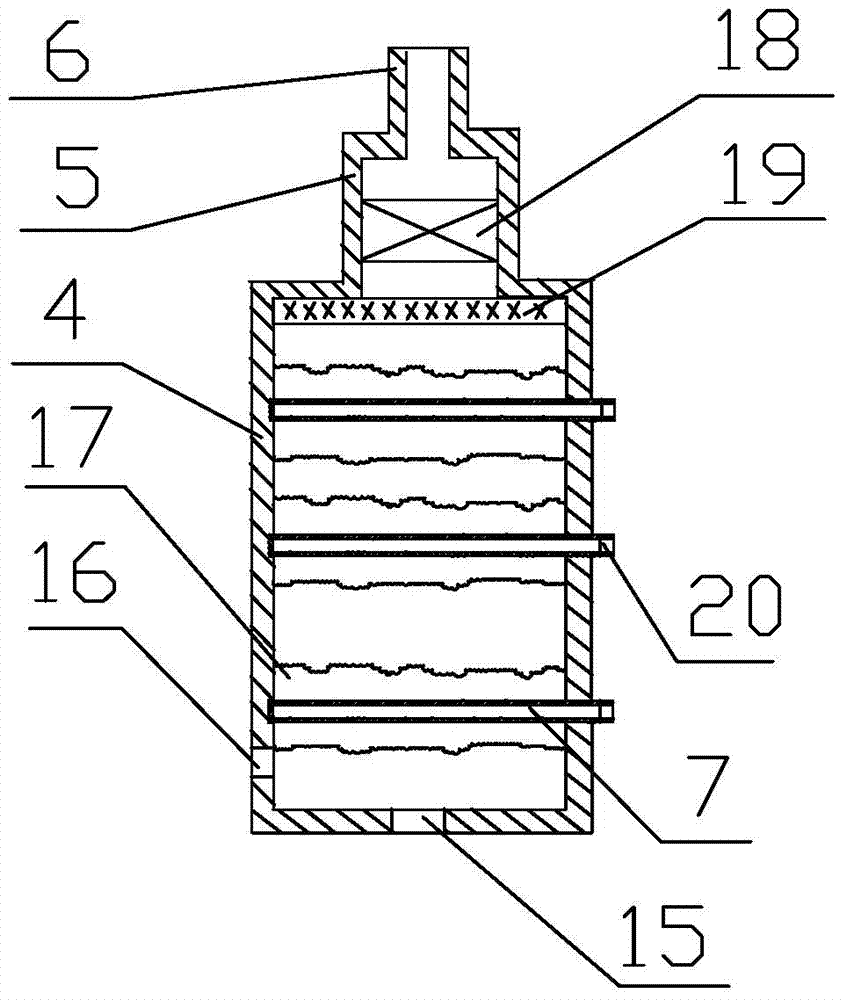

[0010] A waste gas purification device of the present invention will be further described in conjunction with schematic diagrams below. figure 1 A schematic structural diagram of an exhaust gas purification device of the present invention, figure 2 It is a schematic cross-sectional view of a washing tower in an exhaust gas purification device of the present invention. The whole device includes a waste gas flow adjustment device, a washing tower and a washing liquid recovery input device. The middle of the washing tower contains several washing liquid atomization areas 17, and a fixed demisting net is arranged on the top of the washing tower body 4 19. The demister net is a screen made of stainless steel, which is installed at the connection between the tower body and the tower neck; an unpowered centrifugal demist device 18 is installed on the neck of the washing tower, and the unpowered centrifugal demist device is A device similar to a windmill, with a rotating shaft in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com