Energy-saving gas cooker with fin plate heat exchanger

A technology for heat exchangers and gas stoves, applied in heating fuel, gaseous heating fuel, household stoves, etc., can solve the problem of small heat exchange area between hot exhaust gas and combustion-supporting air, improve thermal efficiency and furnace temperature, and reduce energy consumption , noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

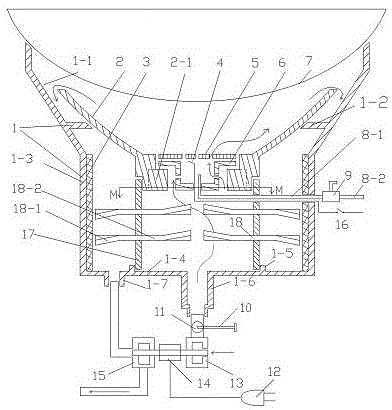

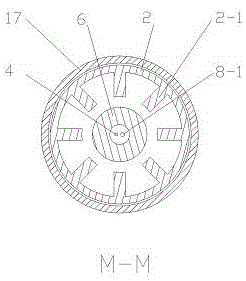

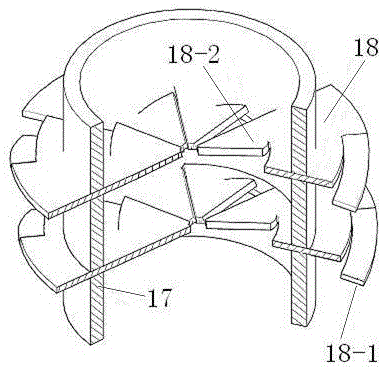

[0017] Embodiment 1, combining figure 1 , figure 2 , image 3 It is a further description of the present invention. The energy-saving gas stove with finned plate heat exchanger includes the outer wall 1 of the existing gas stove, and the return air wall that is stuck on the inner bump 1-2 of the upper part 1-1 of the outer wall. Plate 2, the air mixing chamber 6 and the combustion head 5 installed on the return air coaming fin plate 2-1, the heat insulation plate 3 attached to the inner wall of the lower part 1-3 of the outer coaming plate, the ignition electrode 4 and the ignition switch 16 connected to the The combustible gas pipeline 8-1 respectively passes through the hole on the lower part 1-3 of the outer coaming, the hole on the heat shield 3, the hole on the heat exchange tube 17, the bottom hole of the gas mixing chamber to the gas mixing chamber 6, and is located at The air volume control replica 11 at the outlet of the blower 13, the air volume control rotating r...

Embodiment 2

[0024] Example 2 combined Figure 4 , Figure 5 For further description, in embodiment 2, because the finned plate heat exchanger is formed by casting or stretching, the heat exchange tube 19 and the inner axial cold air fin plate 19- 2. The outer axial hot air fin 19-1 has an integrated structure. In order to increase the heat exchange effect, the cold air fin plate 19-2 and the hot air fin plate 19-1 are opposite to the heat exchange tube 19, and a gap 19-3 is provided on the hot air fin plate 19-1 to reduce heat axial conduction. The upper end 19-4 of the heat exchange tube 19 of the heat exchanger (without the fin plate) is opposite to the annular gap at the lower end of the return air coaming fin plate 2-1, and the lower end 19-5 of the heat exchange tube 19 (without the fin plate) is inserted into the The inner side of the ring-shaped convex edge 1-5 provided on the bottom 1-4 of the outer layer coaming plate is formed by the heat exchange tube 19 and its fin plates 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com