Waste gas residual heat reclaiming system with metering device

A technology of waste heat recovery system and metering device, which is applied in indirect heat exchangers, climate sustainability, lighting and heating equipment, etc. The effect of fire hazard, radiation reduction and workshop temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

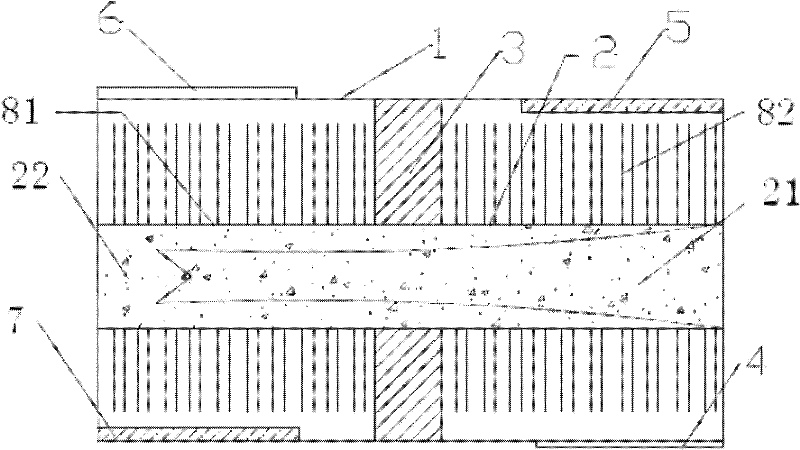

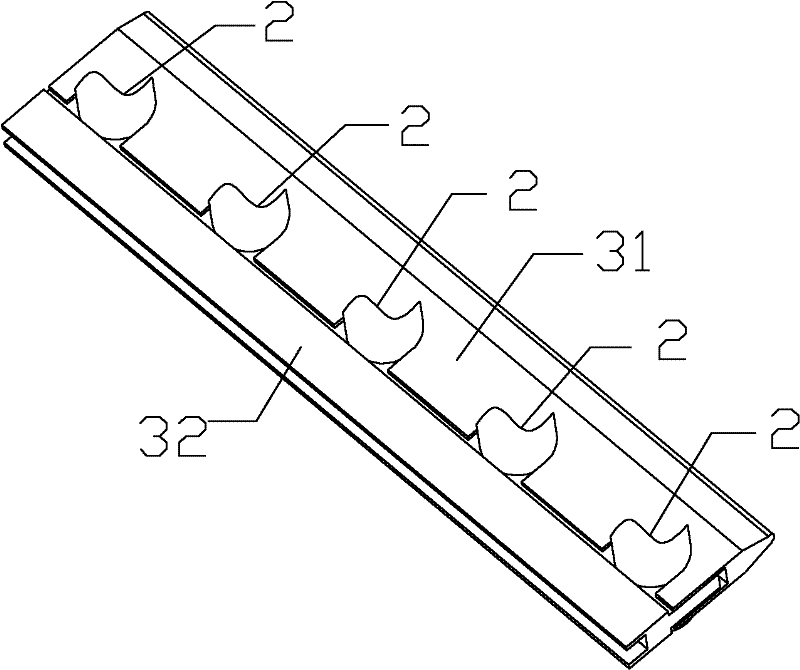

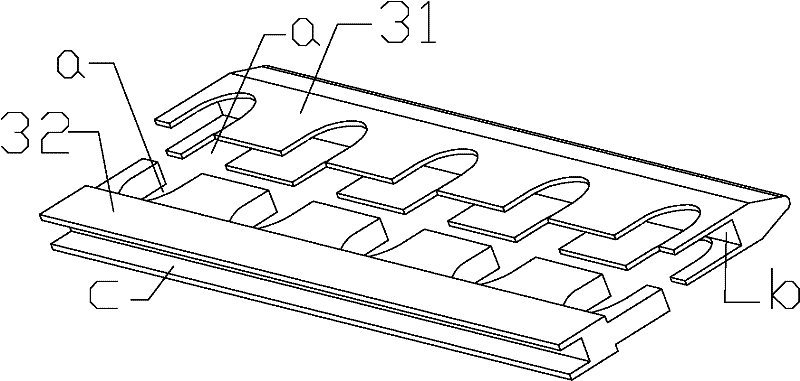

[0030] With reference to accompanying drawing, further illustrate the present invention:

[0031] Exhaust gas waste heat recovery system with metering device, including a box body 1 and a heat pipe 2 arranged inside the box body 1. The heat pipe 2 is covered with a partition that separates the inner cavity of the box into an exhaust gas sub-chamber and a fresh air sub-chamber 3. The exhaust gas sub-chamber is provided with a high-temperature exhaust gas inlet 4 and a low-temperature exhaust gas outlet 5 formed after heat exchange, and the fresh air sub-chamber is provided with a low-temperature fresh air inlet 6 and high-temperature fresh air formed after heat exchange Outlet 7; the evaporation section 21 of the heat pipe 2 is located in the exhaust gas sub-chamber, and the condensation section 22 is located in the fresh air sub-chamber;

[0032] The low-temperature new air inlet 6 is provided with an inlet temperature sensor for obtaining the temperature before the new air en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com