A method for compounding two kinds of copper alloys on the blank of plunger pump cylinder

A technology of copper alloy and plunger pump, which is applied in the direction of cylinders, pistons, engine components, etc., to achieve the effects of reducing pores, avoiding uneven distribution, and increasing nucleation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

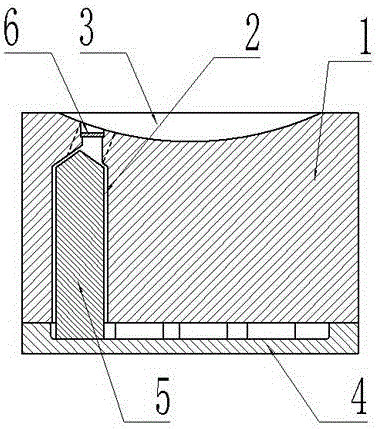

[0032] As shown in the figure, there is a spherical concave surface 3 in the center of the top of the hydraulic plunger pump cylinder blank 1, and a circle of cylindrical cylinder holes 2 is arranged inside the blank 1, a total of 7, and there is a gap between the cylinder hole 2 and the spherical concave surface 3. The connecting channel, the connecting channel is a vertical stepped hole, designed with a dividing plate 6, which can be installed in the stepped hole.

[0033] Before compounding, a diversion groove 4 is first installed at the bottom of the blank 1, and the diversion groove 4 can connect the bottoms of the seven cylinder holes 2 into a cavity. Seven mandrels 5 are installed on the diversion groove 4, and the core The upper end of the rod 5 is inserted in the hole 2 of the cylinder body.

[0034] The composite steps are as follows:

[0035] 1. Use absolute ethanol as a cleaning agent to clean the casting surface of the blank 1, and then apply or place a metal act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com