A medical precision regulator assembly device and assembly method thereof

A technology for assembling devices and regulators, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult repair and maintenance, high precision of debugging, and long cost recovery period, so as to achieve low production cost and high product quality. Excellent quality and the effect of saving assembly cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

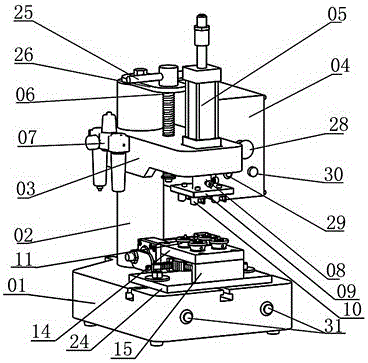

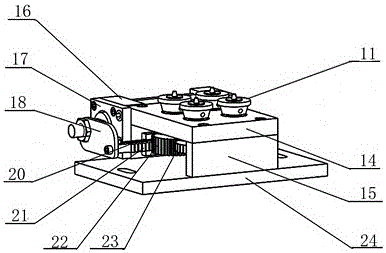

[0035] figure 1 It is a structural diagram of a medical precision regulator assembly device, such as figure 1 and figure 2 As shown, a medical precision regulator assembly device includes: a mechanical structure part, an upper mold tooling part, a lower mold tooling part, a power supply and a control system;

[0036] The mechanical structure part includes: workbench 01, support column 02 and lifting platform 03, the support column 02 is vertically fixed to the workbench 01, and the lifting platform 03 is installed to the support column 02 through a circular hole that can be lifted and connected;

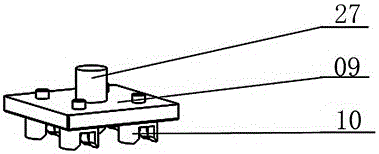

[0037] Upper mold tooling part, including: adjustable stroke cylinder 05, upper template 09 and multiple upper molds 10, adjustable stroke cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com