Cutting fluid recycling device

A recovery device and cutting fluid technology, which is applied in the direction of grinding/polishing equipment, maintenance and safety accessories, mobile filter element filters, etc., can solve the problems of mixed metal fragments, low processing accuracy, complex structure, etc., and achieve cost reduction Low cost, good recycling quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

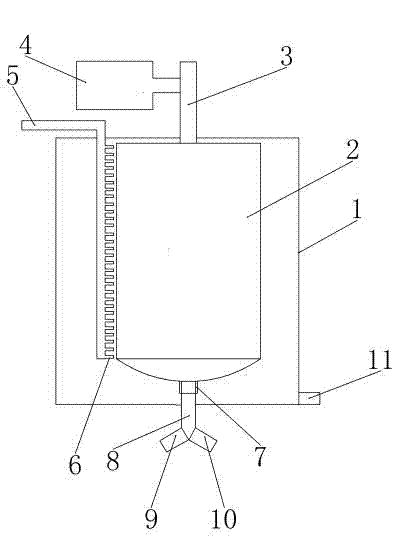

[0013] Such as figure 1 As shown, the present invention provides a cutting fluid recovery device, including a casing 1, the casing 1 is provided with a liquid outlet pipe 11 and a shock absorber, and a centrifugal roller 2 is pivotally connected to the casing 1, and the centrifugal roller 2 The side of the centrifugal roller 2 is a sieve-like dense hole, one end of the centrifugal roller 2 is connected to the rotating shaft 3, and the rotating shaft 3 is connected to the motor 4, and the funnel-shaped end of the centrifugal roller 2 is connected to the main pipe 8 through the sealing ring 7, and the main pipe 8 is connected to the feeder in a branched manner. Material pipe 9 and outlet pipe 10, housing 1 is provided with recoil water pipe 5, said recoil water pipe 5 is provided with water spray head 6 aimed at centrifugal roller 2, and water spray head 6 is along the centrifugal roller 2. A row of sprinkler heads 6 arranged radially.

[0014] The cutting fluid with metal frag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com