Production line and production method of thermoplastic composite material prepreg unidirectional tape

A technology of composite materials and unidirectional belts, which is applied in the production of thermoplastic composite materials, can solve the problems of poor fluidity and inability to automatically penetrate fibers, etc., and achieve the effects of high heat resistance, good toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

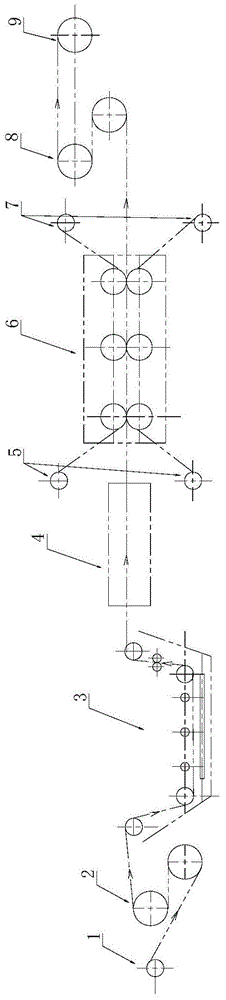

[0050] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

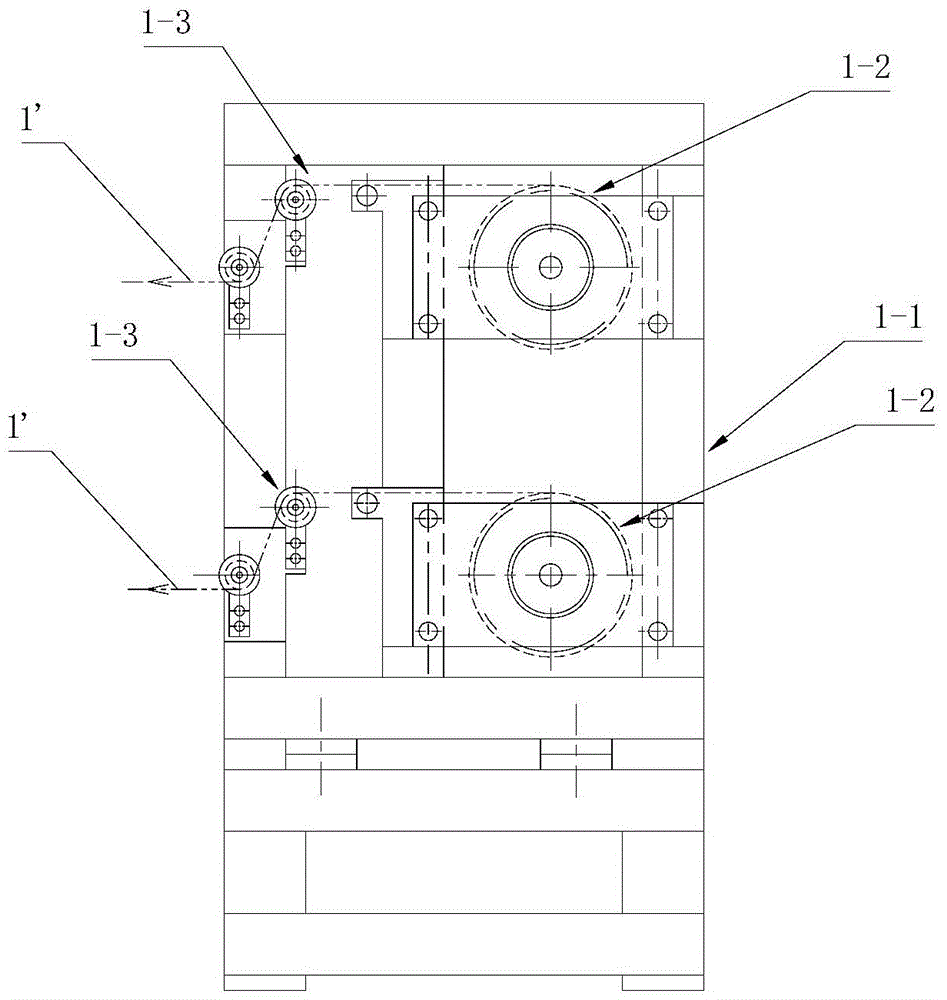

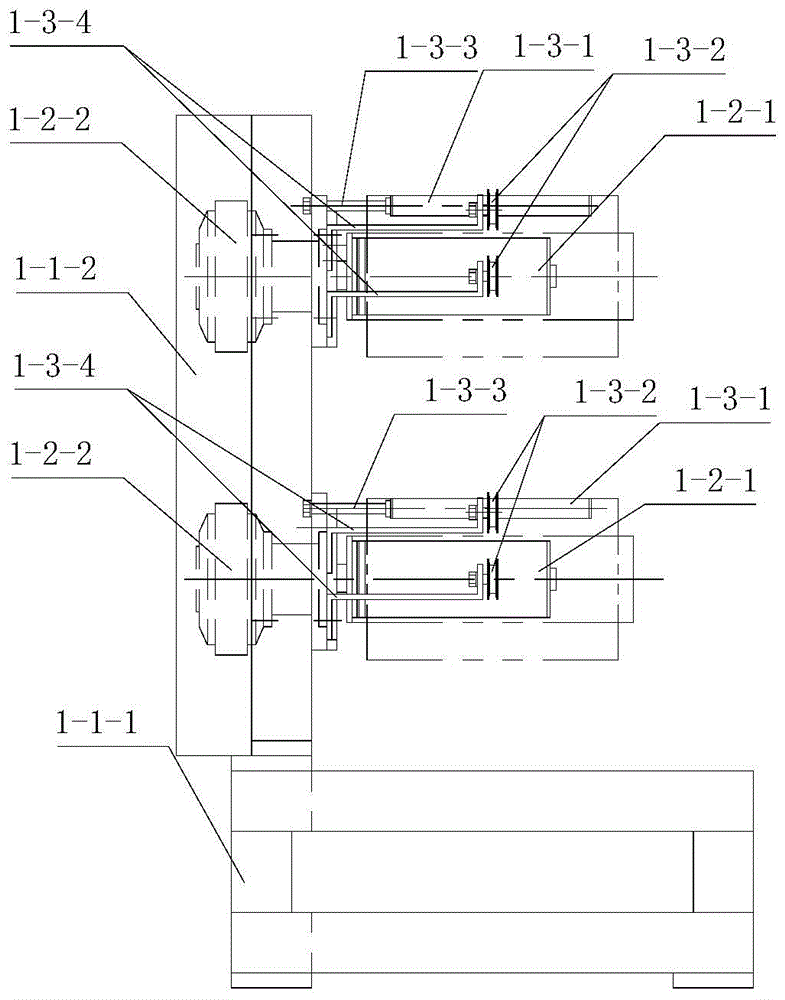

[0051] refer to Figure 1-16 , a production line for thermoplastic composite material prepreg unidirectional tape, consisting of a fiber unwinding device 1, a front-end traction device 2, a water immersion device 3, a preheating device 4, a film unwinding device 5, a hot pressing device 6, a film collecting device The winding device 7, the rear-end traction device 8 and the one-way belt winding device 9 are sequentially connected to form, and the specific structure of each device is as follows:

[0052] The fiber unwinding device includes a yarn unwinding frame 1-1, and the yarn unwinding frame is composed of a yarn unwinding base frame 1-1-1 and a yarn unwinding stand 1-1-2 arranged at the upper end of the yarn unwinding base frame Composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com