Molded pulp tray with composite structure and production method thereof

A pulp molding and composite structure technology, applied in rigid containers, containers, packaging, etc., can solve the problems of easy damage to natural ecology, poor strength and rigidity, and damage to the plastic environment, and achieve low price, light weight, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention will be described in detail below with reference to the accompanying drawings.

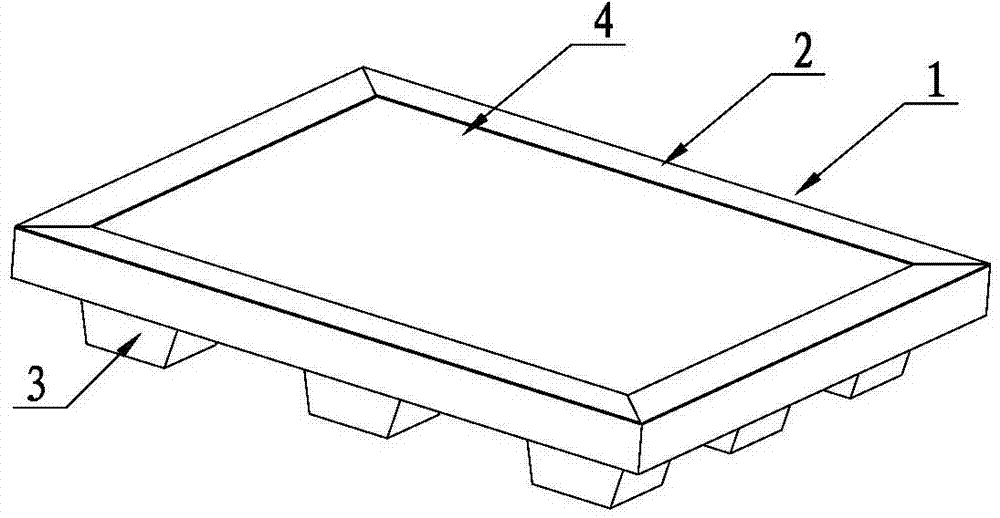

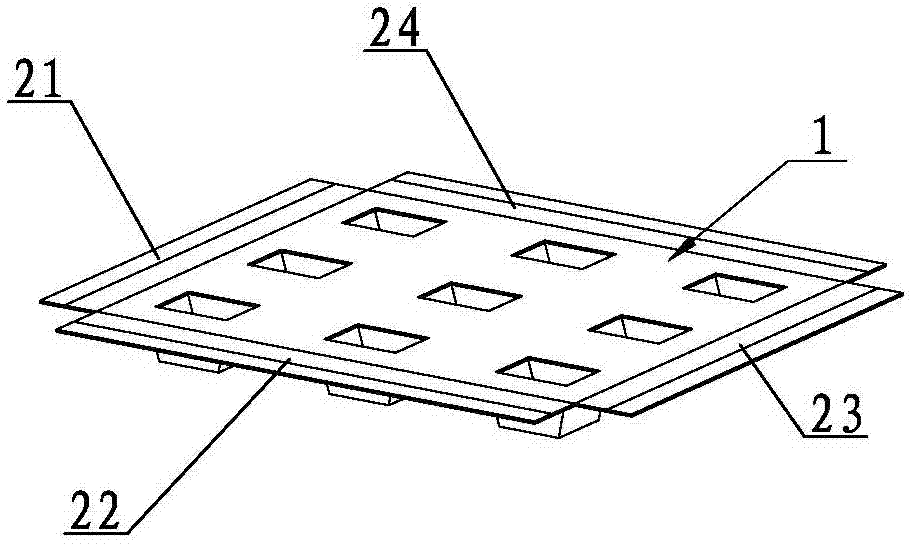

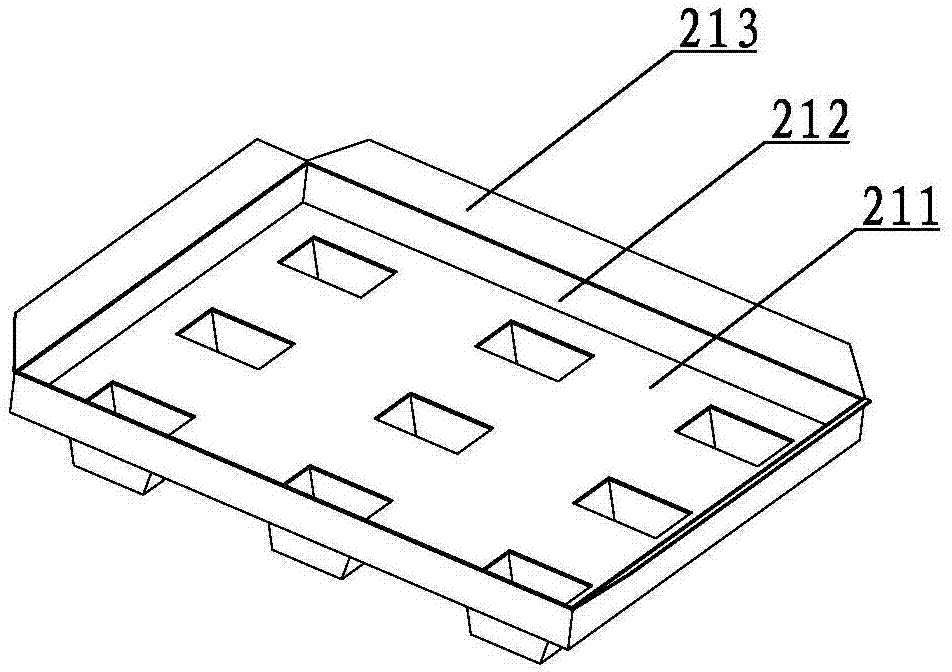

[0039] See Figure 1 to Figure 13 , A molded pulp tray with a composite structure, comprising a molded pulp body 1, the molded pulp body 1 including a packaging component 2 and a number of hollow supporting feet 3 arranged below the packaging component 2, the A honeycomb-filled cardboard or several layers of corrugated cardboard 5 are arranged in the supporting leg 3, a honeycomb cardboard 4 is arranged above the supporting leg 3, and the periphery of the packaging assembly 2 is bent into a shape and covered and connected to the outer side of the honeycomb cardboard 4 . The pulp molded tray adopts the packaging combination of the pulp molded body structure on the honeycomb paperboard 4 and the corrugated paperboard 5 in the structure. Because the honeycomb paperboard 4 has the advantages of light weight, low price and high strength, especially its honeycomb structure has a large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com