Oil product storage tank safety protection device and protection method

A safety protection device and technology for oil products, applied in packaging, transportation, packaging, containers, etc., can solve the problems of accelerating the volatilization speed of oil surface, and achieve the effect of simple protection method, elimination of hidden dangers of explosion and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

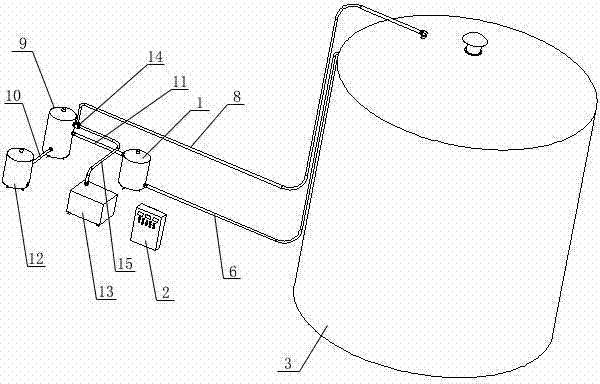

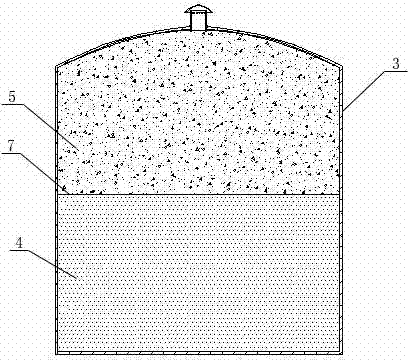

[0028] Embodiment 1: as figure 1 , figure 2 , Figure 5 As shown, an oil storage tank safety protection device includes a gas analysis unit, an inhibitor supply unit 1, and a control unit 2. The gas analysis unit includes an air extraction sampling analysis system 13, and the air extraction sampling analysis system 13 passes The main air extraction pipe 8 is connected to the mixed gas space 5 formed above the liquid level of the oil product 4 in the oil storage tank 3, the inhibitor supply unit 1 is connected to the oil storage tank 3 through the inhibitor supply pipe 6, and the control unit 2 is respectively It is connected with the air pumping sampling analysis system 13 and the inhibitor supply unit 1, and the inhibitor injected into the oil storage tank 3 by the inhibitor supply unit 1 through the inhibitor supply pipe 6 forms a liquid film protective layer on the liquid surface of the oil product 4 7.

[0029]Wherein, the mixed gas space 5 in the oil storage tank 3 is...

Embodiment 2

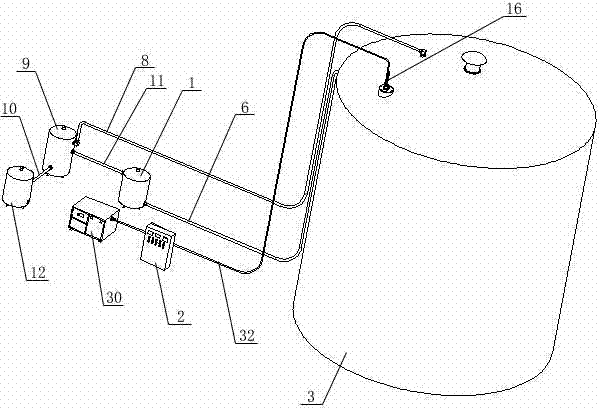

[0034] Embodiment 2: as Figure 3 ~ Figure 4 , Figure 6 ~ Figure 10 As shown, the gas analysis unit includes a bidirectional self-cleaning fiber optic gas sensor sensing head 16 arranged on the oil storage tank 3, and the bidirectional self-cleaning fiber optic gas sensor sensing head 16 includes a fiber optic signal transceiver unit, a fiber optic signal Reflection unit and bi-directional purge unit.

[0035] Wherein, the optical fiber signal transceiver unit includes an optical fiber group 17 and a two-way light-transmitting mirror 18, the optical fiber group 17 is connected to the control unit 2 through a laser transmitter, a sheath 20 is placed on the optical fiber group 17, and the sheath 20 The coated optical fiber group 17 is connected to the inner hole of the positioning sleeve 21, and the positioning sleeve 21 is fixedly connected with the end surface of the main body 22 after being positioned, and the positioning sleeve and the main body are fastened by threads; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com