A kind of bismuth yttrium oxide nanorod and its preparation method and application

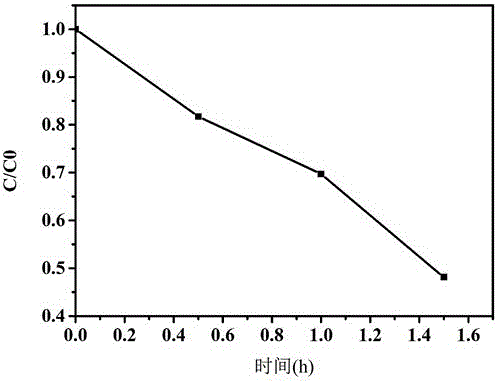

A technology of nanorods and bismuth yttrium oxide, which is applied in the field of bismuth yttrium oxide nanorods and its preparation, can solve problems such as poor morphology of bismuth yttrium oxide, achieve high practical application ability, good reproducibility, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh bismuth nitrate and yttrium nitrate and dissolve in 10ml, 0.1mol / L -1 In dilute nitric acid, the masses of the bismuth nitrate and yttrium nitrate are 0.2425g and 0.1916g respectively.

[0027] (2) The mixed solution in step 1 was ultrasonically stirred for 1 h to obtain a clear and transparent liquid.

[0028] (3) Transfer the liquid obtained in step 2 to a polytetrafluoroethylene-lined reactor, and 4 ∙ H 2 O to adjust the pH value to 8; add water to 80% of the reactor volume.

[0029] (4) The reaction kettle in step 3 was kept in a temperature range of 180ºC, and reacted at a constant temperature for 48 hours to obtain a precipitate.

[0030] (5) Wash the precipitate obtained in step 4 alternately with water and ethanol, and centrifuge.

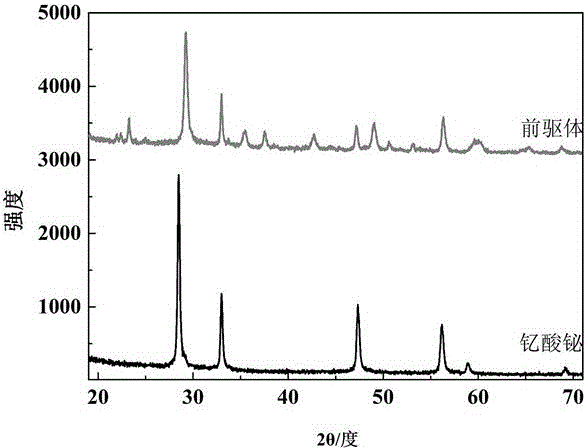

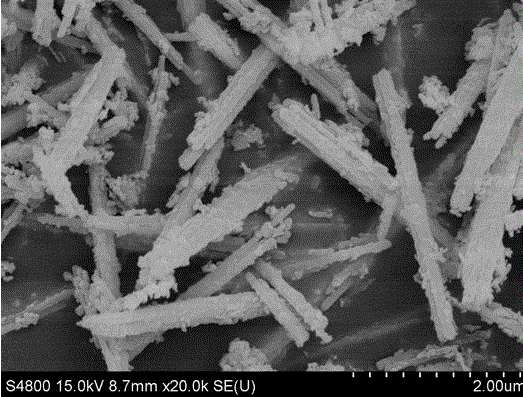

[0031] (6) Calcining the centrifuged product in step 5 at a high temperature to remove impurities to obtain pure-phase bismuth yttrium nanorods. The high-temperature calcination temperature is 450°C, the calcination tim...

Embodiment 2

[0033] (1) Weigh bismuth nitrate and yttrium nitrate and dissolve in 10ml, 0.1mol / L -1 In dilute nitric acid, the masses of the bismuth nitrate and yttrium nitrate are 0.2425g and 0.1916g respectively.

[0034] (2) The mixed solution in step 1 was ultrasonically stirred for 1 h to obtain a clear and transparent liquid.

[0035] (3) Transfer the liquid obtained in step 2 to a polytetrafluoroethylene-lined reactor, and 4 ∙ H 2 O to adjust the pH value to 8.5; add water to 80% of the reactor volume.

[0036] (4) The reaction kettle in step 3 was kept in a temperature range of 200 ºC for 24 hours at a constant temperature to obtain a precipitate.

[0037] (5) Wash the precipitate obtained in step 4 alternately with water and ethanol, and centrifuge.

[0038] (6) The centrifuged product in step 5 is calcined at high temperature to remove impurities, so as to obtain pure phase bismuth yttrium nanorods. The temperature of high-temperature calcination is 550°C, the calcination tim...

Embodiment 3

[0040] (1) Weigh bismuth nitrate and yttrium nitrate and dissolve in 10ml, 0.1mol / L -1 In dilute nitric acid, the masses of the bismuth nitrate and yttrium nitrate are 0.2425g and 0.1916g respectively.

[0041] (2) The mixed solution in step 1 was ultrasonically stirred for 1 h to obtain a clear and transparent liquid.

[0042] (3) Transfer the liquid obtained in step 2 to a polytetrafluoroethylene-lined reactor, and 4 ∙ H 2 O to adjust the pH value to 9; add water to 80% of the reactor volume.

[0043] (4) The reaction kettle in step 3 was kept in a temperature range of 240 ºC for 16 hours at a constant temperature to obtain a precipitate.

[0044] (5) Wash the precipitate obtained in step 4 alternately with water and ethanol, and centrifuge.

[0045] (6) Calcining the centrifuged product in step 5 at a high temperature to remove impurities to obtain pure-phase bismuth yttrium nanorods. The high-temperature calcination temperature is 650°C, the calcination time is 2h, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com