Quenching and collecting device for gasified molybdenum oxide nanoparticles

A nanoparticle and collection device technology, applied in the direction of molybdenum oxide/molybdenum hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of unstable product quality, complicated process, low efficiency, etc., and achieve high production efficiency, simple process, The effect of high anger efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

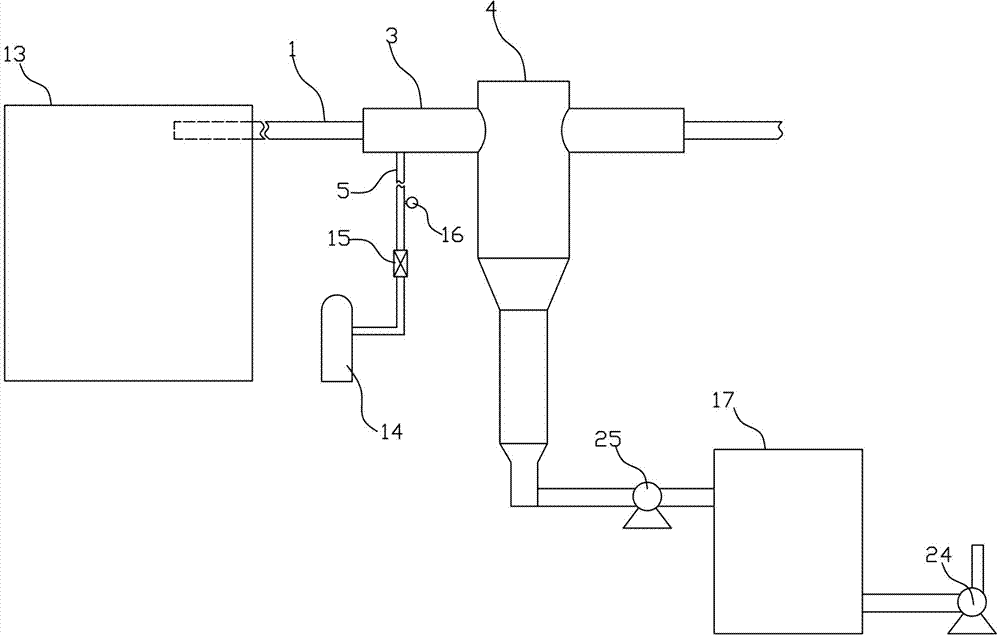

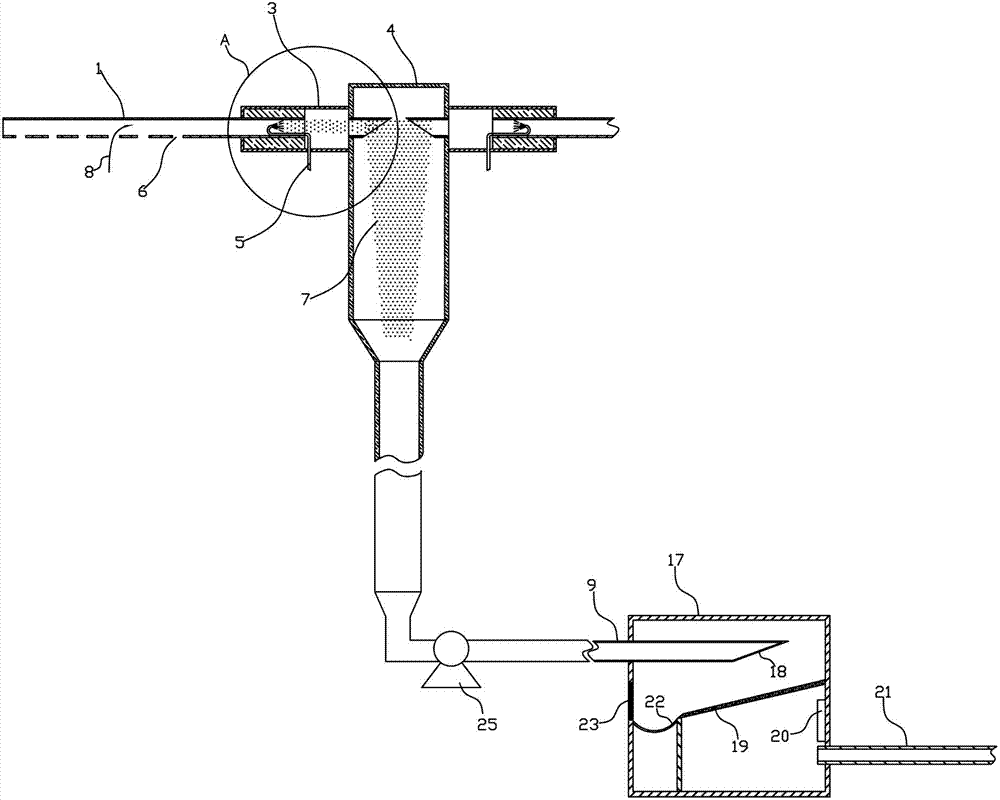

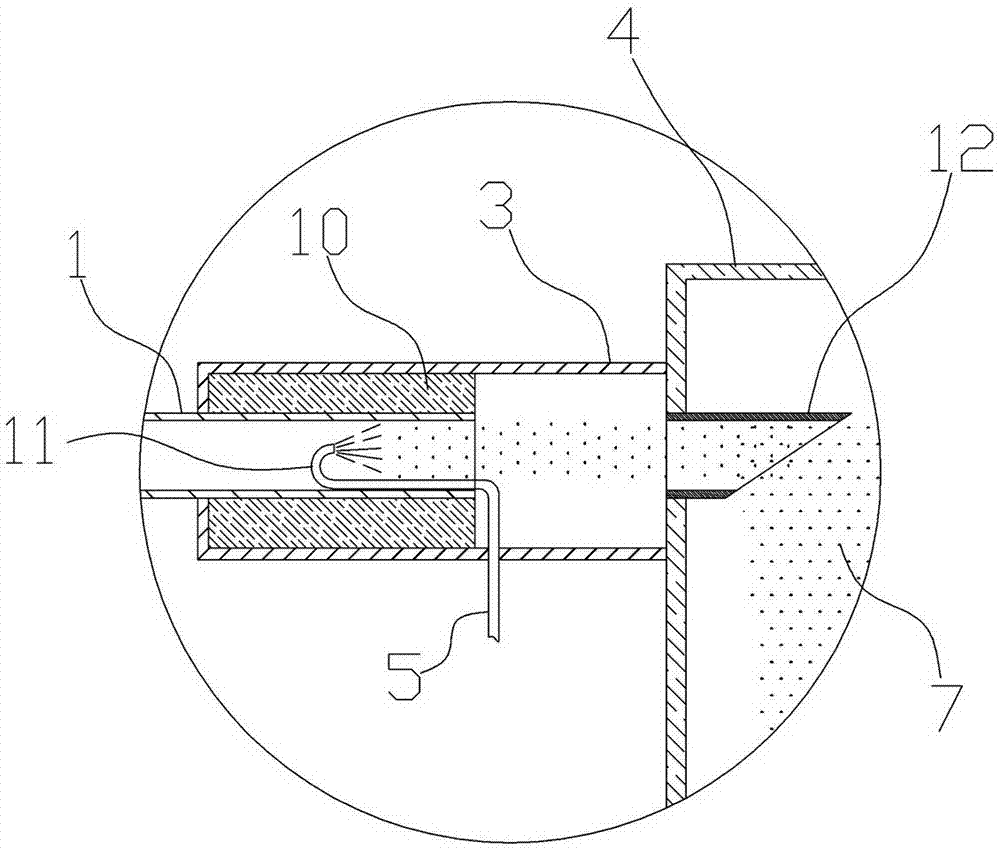

[0027] Embodiment 1: A kind of gasification state molybdenum oxide nano particle quenching, collection device, see figure 1 , figure 2 , image 3 The device includes a gasifier for gasifying the precursor material of molybdenum oxide nanoparticles, a quenching unit for quenching the gasified molybdenum oxide nanoparticles, and collecting molybdenum oxide nanoparticles A collection unit for finished products;

[0028] The quenching unit includes a collection pipe 4, two openings at its left and right ends, and its inlet port is correspondingly arranged in the gasifier, and is used to collect the collection pipe 1 of gasified molybdenum oxide nanoparticles, and its diameter is larger than The protection pipe fitting 3 of the diameter of collecting pipe; The air outlet port of described collecting pipe 1 is correspondingly arranged in the middle part in protecting pipe fitting 3; A thermal insulation layer 5 is arranged in the middle of the pipe fitting 3, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com