Biological treatment device of wastewater and cultivation method of aerobic granular sludge

An aerobic granular sludge and granular sludge technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor removal effect and affect the sedimentation effect of the secondary sedimentation tank , long reaction time and other problems, to achieve the effect of fast sludge granulation process, easy promotion and application, and good ammonia nitrogen removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

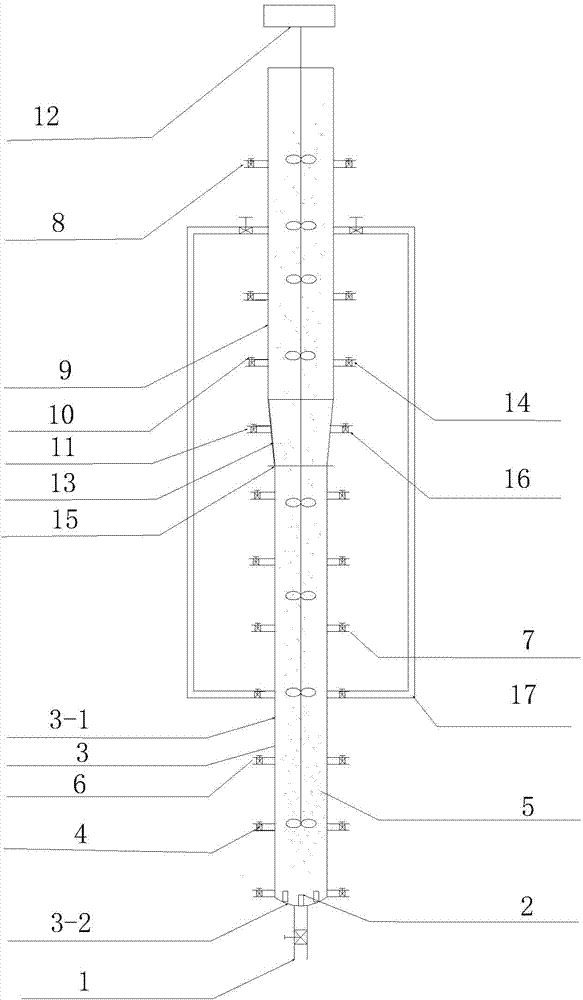

[0025] Specific Embodiment 1: Combining figure 1 This embodiment is described. This embodiment consists of an upper reaction zone and a lower reaction zone. The lower reaction zone includes a water inlet pipe (1), a lower reaction cylinder (3), a plurality of first valve bodies (4), an aerobic particle pollution Mud (5), multiple first sampling pipes (6), first water outlet (7) and gas distribution device (2) in the lower reaction zone; the lower reaction cylinder (3) consists of the lower cylinder (3-1) and Composed of conical bottom cylinder (3-2), the lower cylinder body (3-1) is connected to the conical bottom cylinder (3-2) through a flange, and the water inlet pipe (1) is installed on the conical bottom cylinder (3-2) ) and communicated with the conical bottom cylinder (3-2); the granular sludge (5) is arranged in the lower cylinder (3-1), and a plurality of first sampling pipes (6) are along the lower reaction cylinder ( 3) is axially installed on the outer wall of the...

specific Embodiment approach 2

[0027] Specific Embodiment 2: Combining figure 1 The present embodiment will be described. The upper part of the lower reaction cylinder of the present embodiment is drained. With such setting, the granulation of heterotrophic floc sludge can be realized within 10-30 days. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: Combining figure 1 The present embodiment will be described. The upper part of the lower reaction cylinder of the present embodiment is drained. With such setting, the granulation of the autotrophic floc sludge can be realized within 10-50 days, and then the nitrification granular sludge can be formed. Other compositions and connections are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com