High slump retention and high strength slump retention agent and preparation method thereof

A slump-preserving agent and high-strength technology, applied in the field of concrete, can solve the problems of excessive concrete slump loss, and achieve the effects of increasing the slump-preserving function, delaying the slump loss speed, and reducing the shrinkage cracking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

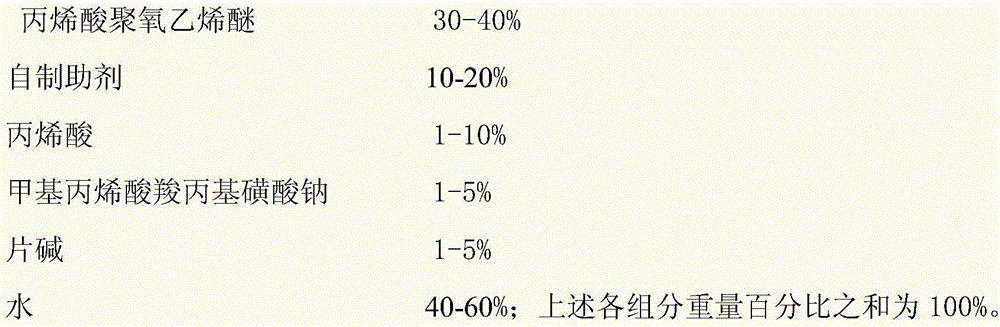

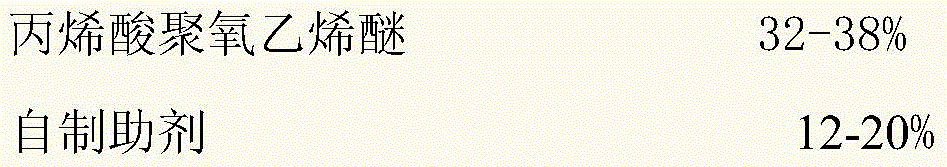

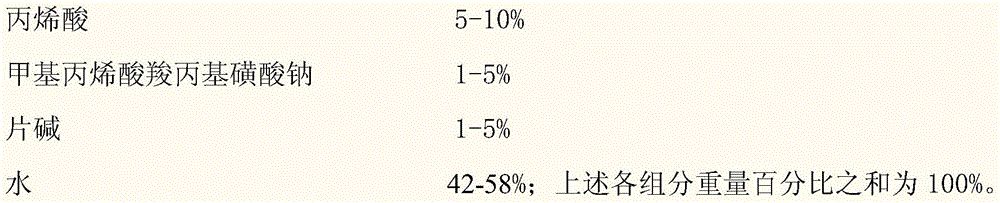

[0023] Raw material ratio:

[0024] Acrylic polyoxyethylene ether 35%, self-made additives 15%, acrylic acid 5%, sodium methacrylate carboxypropyl sulfonate 2%, caustic soda 3%, water 40%.

[0025] Homemade additives: 15% acrylic acid, 5% ammonium persulfate, 80% water.

[0026] The preparation steps include: first, weighing the raw materials of each component according to the formula ratio; heating the water with half the formula ratio to 40°C, then adding polyoxyethylene acrylic acid ether and self-made additives to the water and stirring and mixing evenly; then the temperature of the mixture Raise the temperature to 50°C, add acrylic acid and stir to mix evenly, then raise the temperature of the reaction system to 60°C; keep the heated material in step (2) warm and mix and stir to react for 2 hours, then add carboxypropyl sulfonyl methacrylate dropwise Add the solution of sodium bicarbonate and water mixed with the other half of the formula ratio to the reaction system, an...

Embodiment 2

[0028] Raw material ratio:

[0029] Acrylic acid polyoxyethylene ether 40%, self-made additives 10%, acrylic acid 8%, sodium methacrylate carboxypropyl sulfonate 1%, caustic soda 1%, water 40%.

[0030] Homemade additives: 18% acrylic acid, 8% ammonium persulfate, 74% water.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] Acrylic polyoxyethylene ether 32%, self-made additives 18%, acrylic acid 5%, sodium methacrylate carboxypropyl sulfonate 1%, caustic soda 1%, water 43%.

[0034] Homemade additives: 20% acrylic acid, 2% ammonium persulfate, 78% water.

[0035] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com