High-nitrogen-content polymeric microsphere and preparation method thereof

A technology of microspheres and polyphosphazene, which is applied in the field of high nitrogen-containing polymer microsphere materials and its preparation, can solve the problems of low nitrogen content, low yield, long reaction preparation time, etc., and achieve the effect of increasing nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment includes the following steps:

[0017] The first step is to react acetonitrile, triethylamine as an acid-binding agent, hexachlorocyclotriphosphazene, and triaminopyrimidine at 150°C for 3 hours, that is, 400 mg of hexachlorocyclotriphosphazene, triaminopyrimidine, and Pyrimidine is 288 mg, in a 200 mL digestion tank, add 60 mL of acetonitrile and 4 mL of triethylamine to the digestion tank in sequence.

[0018] The second step is to wait for the digestion tank to cool down to room temperature naturally in a drying oven; pour the product into a centrifuge tube, and use an ultrasonic cleaner to crush the product with large particles.

[0019] The third step is to centrifuge in a centrifuge at 7200 rpm for 5 minutes, then rinse with an organic solvent and centrifuge again, repeat three times; then dry at 80-100°C to obtain polymer microsphere materials.

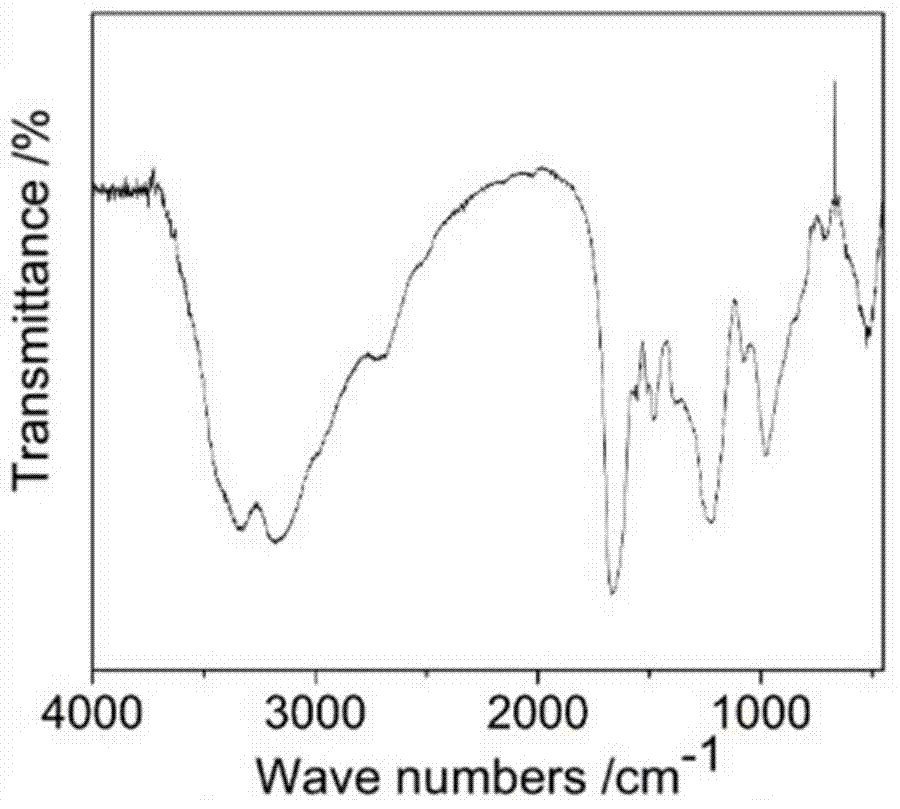

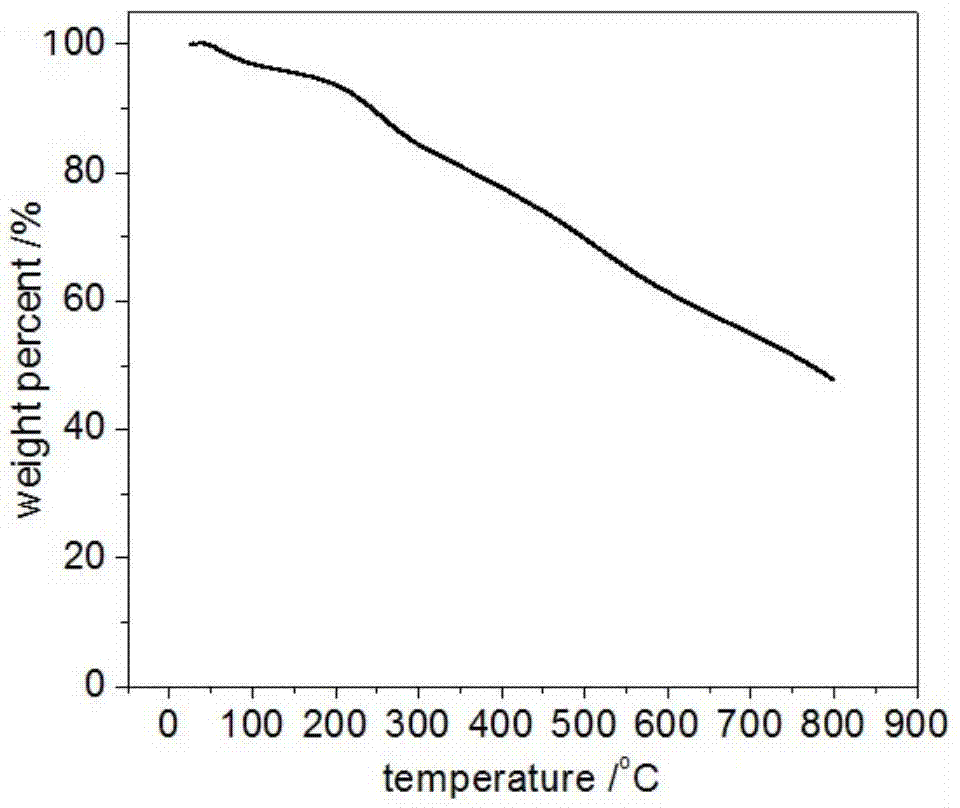

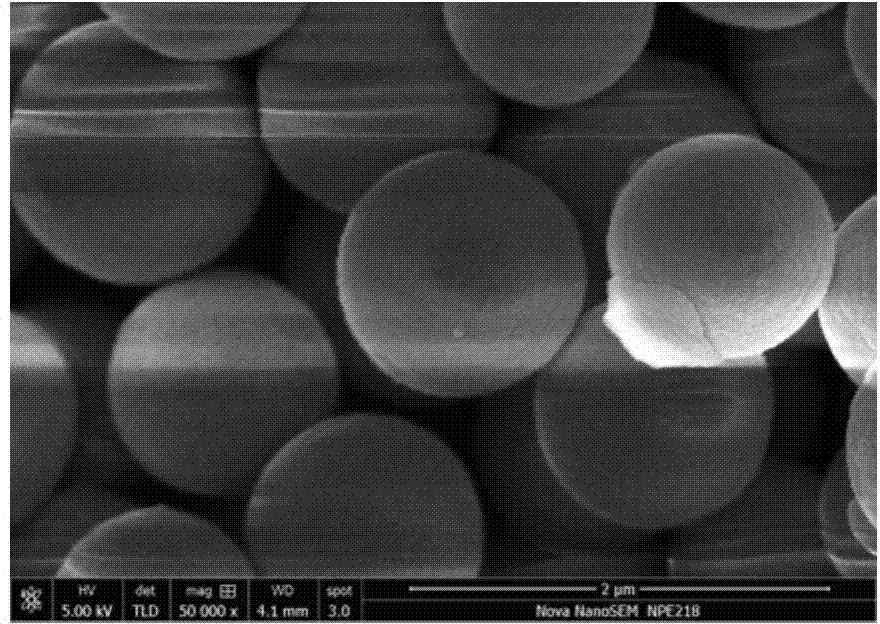

[0020] Such as Figure 1 ~ Figure 3 Shown are the infrared spectrogram, thermogravimetric curve and ...

Embodiment 2

[0022] This embodiment includes the following steps:

[0023] The first step, react acetonitrile, triethylamine, hexachlorocyclotriphosphazene, and triaminopyrimidine at 150°C for 3 hours, that is, 200 mg of hexachlorocyclotriphosphazene and triaminopyrimidine are used for a single preparation. Pyrimidine is 144 mg. In a 200 mL digestion tank, add 60 mL of acetonitrile and 2 mL of triethylamine to the digestion tank in sequence.

[0024] The second step is to wait for the digestion tank to cool down to room temperature naturally in a drying oven; pour the product into a centrifuge tube, and use an ultrasonic cleaner to crush the product with large particles.

[0025] The third step is to centrifuge in a centrifuge at 7200 rpm for 5 minutes, then rinse with an organic solvent and centrifuge again, repeat three times; then dry at 80-100°C to obtain polymer microsphere materials.

Embodiment 3

[0027] This embodiment includes the following steps:

[0028] The first step, react acetonitrile, triethylamine, hexachlorocyclotriphosphazene and triaminopyrimidine at 150°C for 3 hours as an acid-binding agent, that is, the hexachlorocyclotriphosphazene used in a single preparation is 50-150 mg, Triaminopyrimidine is 36-108 mg, in a 200 mL digestion tank, add 60 mL of acetonitrile and 1-3 mL of triethylamine to the digestion tank in sequence.

[0029] The second step is to wait for the digestion tank to cool down to room temperature naturally in a drying oven; pour the product into a centrifuge tube, and use an ultrasonic cleaner to crush the product with large particles.

[0030] The third step is to centrifuge in a centrifuge at 7200 rpm for 5 minutes, then rinse with an organic solvent and centrifuge again, repeat three times; then dry at 80-100°C to obtain polymer microsphere materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com