Innocent treatment method and system for liquid crystal panel

A technology of harmless treatment and liquid crystal panel, which is applied in the field of harmless treatment of hazardous waste, can solve the problems of high treatment cost, complicated process, secondary pollution, etc., and achieve simple operation, simple process flow and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

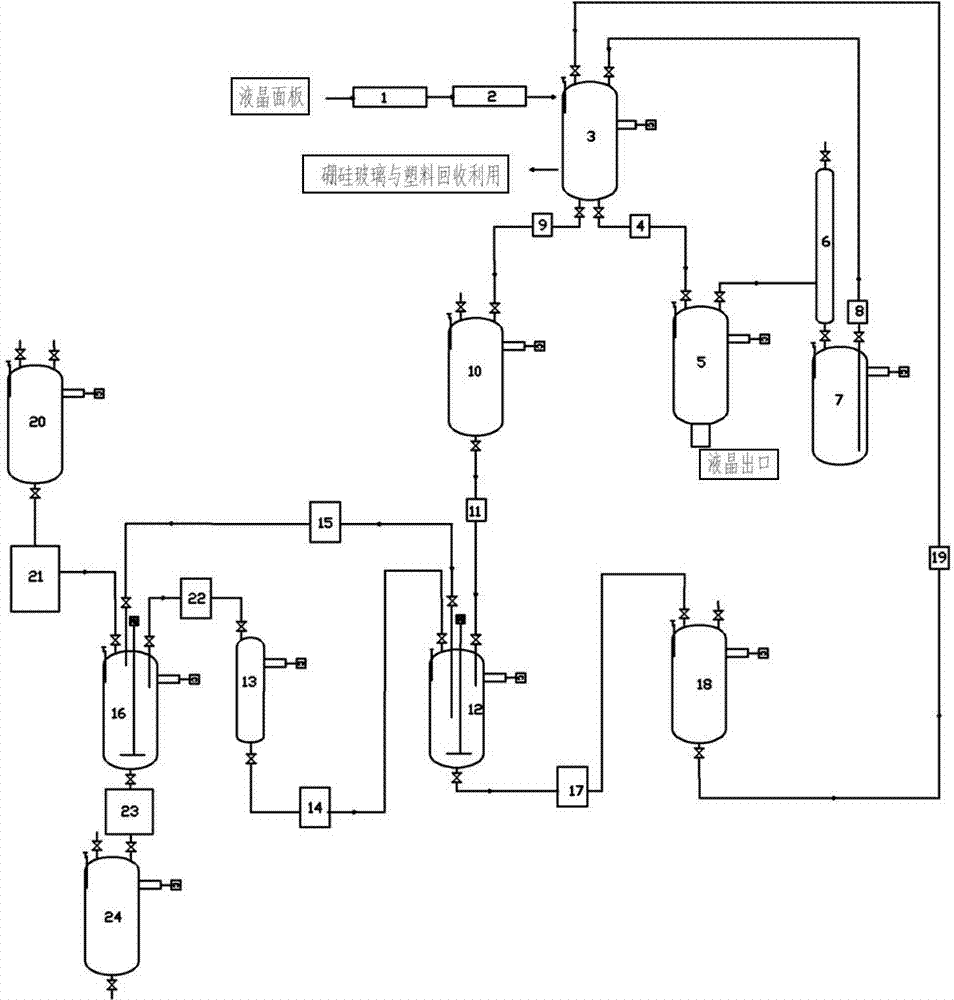

[0043] The harmless treatment process of the liquid crystal panel of the present invention can be briefly described as: A. The liquid crystal panel is broken; B. The broken liquid crystal panel is soaked in acetone solution, and the soaked acetone solution is evaporated and condensed to recover and dissolve in acetone Liquid crystal in the solution; C. Soak the broken liquid crystal panel soaked in acetone solution in sulfuric acid solution, and recover the solid phase residue after soaking; D. Extract and back-extract the sulfuric acid solution soaking liquid, and recycle to obtain indium-containing pure solution. Therefore, while realizing the harmless treatment of the liquid crystal panel, the purpose of recovering the liquid crystal and the precious metal indium is achieved.

[0044] The liquid crystal panel harmless treatment method and system of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0045]The imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com