Active breathing moisture-proof and steam-exhausting inverted roof system and its construction method

A technology of roofing system and construction method, applied in ventilation system, roof ventilation, heating method, etc., can solve the problems affecting the construction speed, quality and life of waterproof layer, cracking failure of membrane waterproof layer, difficult to control the moisture content of base layer, etc. Achieve the effect of reducing roof leakage, good steam exhaust effect and long continuous working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

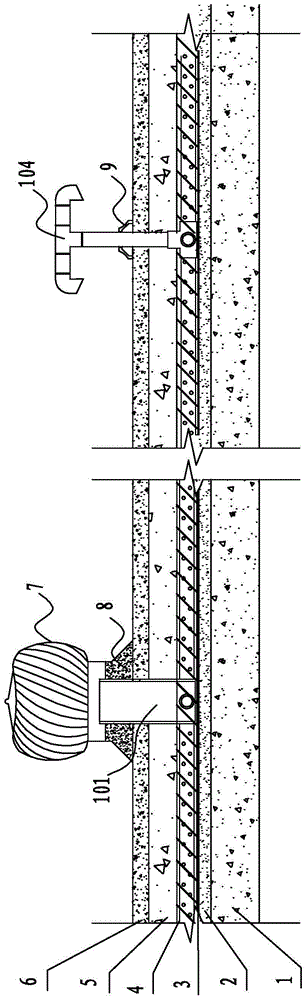

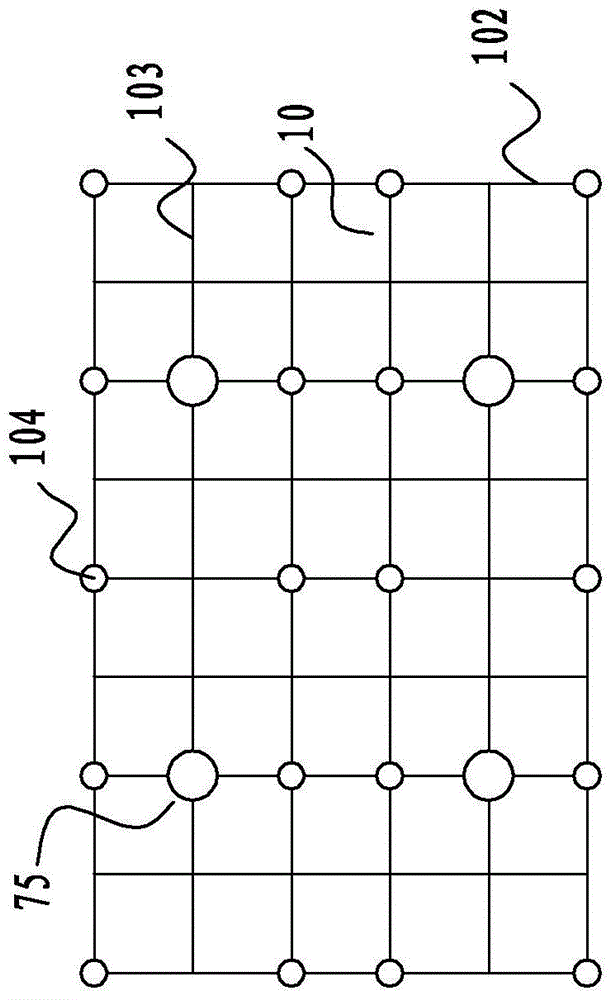

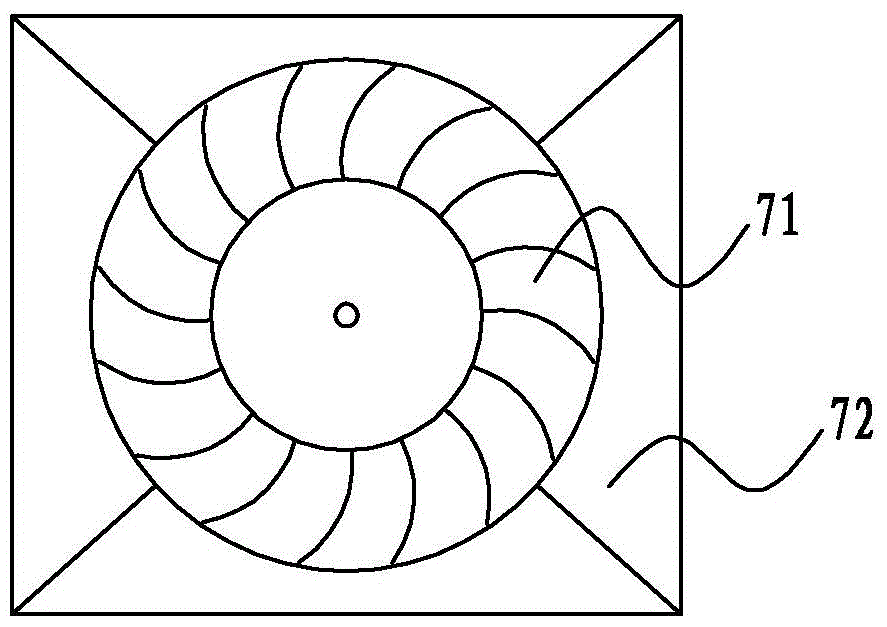

[0060] An active breathing type moisture-proof and exhaust steam inverted roof system, such as figure 1 As shown, the active breathing type moisture-proof and exhaust steam inverted roof system includes a roof structural layer 1 and a roof screed layer 2, a roof waterproof layer 3, a roof insulation layer 4, and a roof slope finding layer, which are sequentially arranged from the inside to the outside on the roof structure layer 1. The roof composed of layer 5 and the roof rigid protective layer 6, an active breathing type moisture-proof exhaust steam system composed of a breathing pipe network system 10 and an unpowered hood device 7;

[0061] The breathing tube network system 10 is an air flow channel, including an outlet breathing vertical tube 101, a breathing horizontal tube 102, a breathing longitudinal tube 103, a T-shaped intake breathing tube 104, a breathing hole 105 and a connector 106; the breathing horizontal tube 102 The adjacent tubes of the breathing longitudinal ...

Embodiment 2

[0068] A construction method of an active breathing type moisture-proof and exhaust steam inverted roof system. The method is a construction method for the active breathing type moisture-proof and exhaust steam inverted roof system described in the first embodiment. It changes the sequence of various traditional roofing processes and is used in the roof An active breathing type moisture-proof exhaust steam system composed of a breathing pipe network system 10 and an unpowered hood device 7 is added; the construction method includes the following steps:

[0069] A. Roof base layer-namely: roof structure layer 1 cleaning and leveling: After cleaning the dust, debris, etc., use cement mortar to carry out roof leveling layer 2 construction on roof structure layer 1, and set corresponding separation joints according to the specifications;

[0070] B. Construction of roof waterproof layer: After the roof leveling layer 2 is dry, carry out roof waterproof layer 3 construction according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com