Indoor aluminum alloy combination suite door

A technology for suiting doors and aluminum alloys, which is applied in the direction of door leaves, window/door frames, etc., can solve the problems of long production cycle, delay in decoration progress, slow smell emission, etc., to avoid formaldehyde volatilization, not easy to crack and deform, and reduce use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

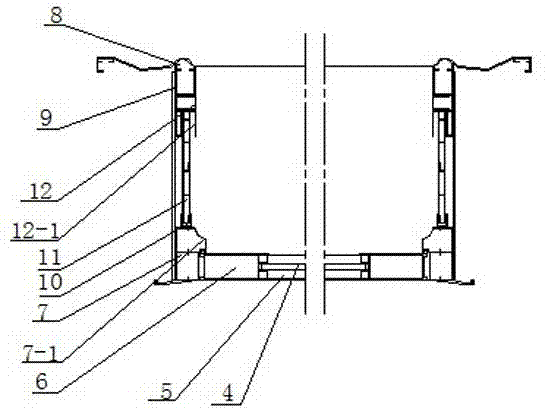

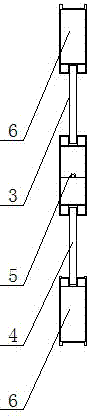

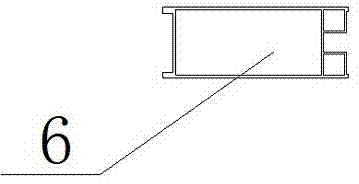

[0016] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the present invention includes a door and a door pocket, and the door includes A door panels 3, B door panels 4, center columns 5 and mullions 6, and the upper and lower sides of the center column 5 are respectively provided with Groove, the inner side of the mullion 6 is provided with grooves, the two ends of the middle column 5 are respectively installed in the mullion 6, and the four sides of the A door panel 3 and the B door panel 4 are respectively embedded in the grooves on the upper and lower sides of the middle column 5 and the inner side of the mullion 6 On the groove, the door cover includes a turn-up frame 7, a front cover 8, a group of connecting plates 9, a U-shaped groove 10, a buckle plate 11 and an F-shaped fastener 12, and an F-shaped fastener installation groove is opened on the front cover 8. The turn-up frame 7 is provided with an arc-shaped boss 7-1, the front cover 8 is movably installed on the turn-up fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com