Preparation method of single-layer nano-metal grating

A nano-metal and nano-grating technology, which is applied in the field of nano-manufacturing, can solve the problems of difficult control of graphic side erosion, many process steps, and high process difficulty, and achieve the effects of low cost, simplified process steps, and high graphic resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a single-layer nano-aluminum grating, the preparation method comprising the steps of:

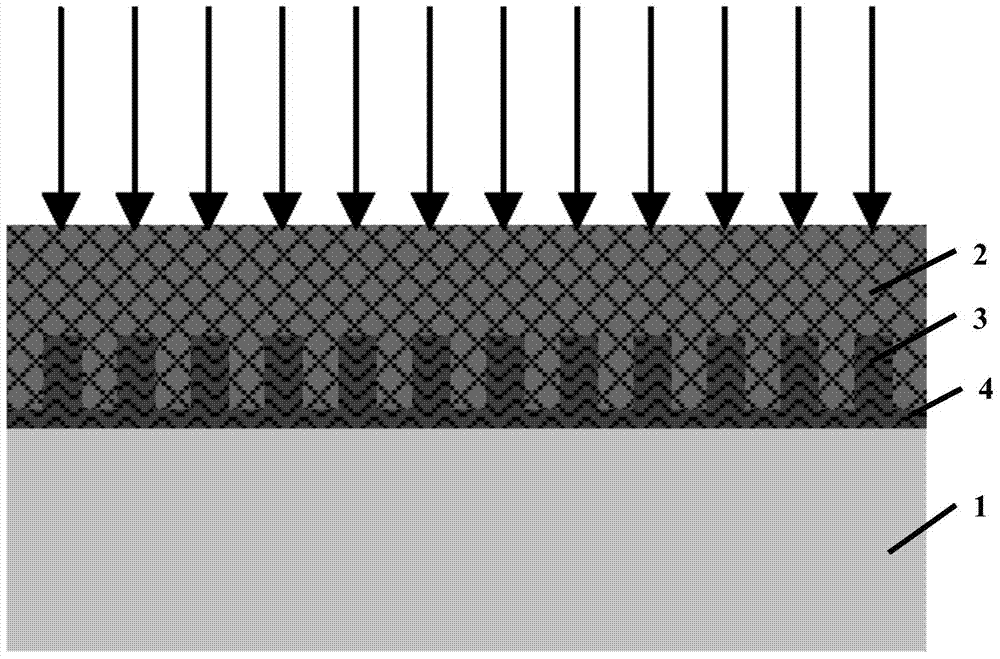

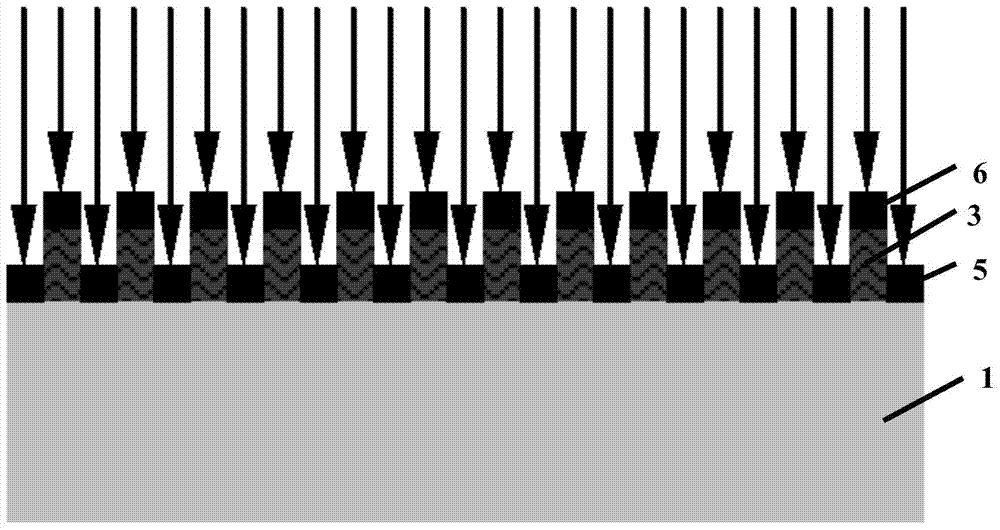

[0028] ①The substrate is spin-coated with imprinting glue first, and then the imprinting template with nano-grating pattern is pressed into the imprinting glue. Using ultraviolet nano-imprinting, the nano-pattern is transferred, the imprinting template and the substrate are separated, and the imprinting glue is formed and embossed. The nano-grating pattern complementary to the imprint template structure, that is, the imprint adhesive layer of the one-dimensional nano-grating structure is obtained, and finally the imprint residual adhesive layer is removed by oxygen reactive ion etching technology;

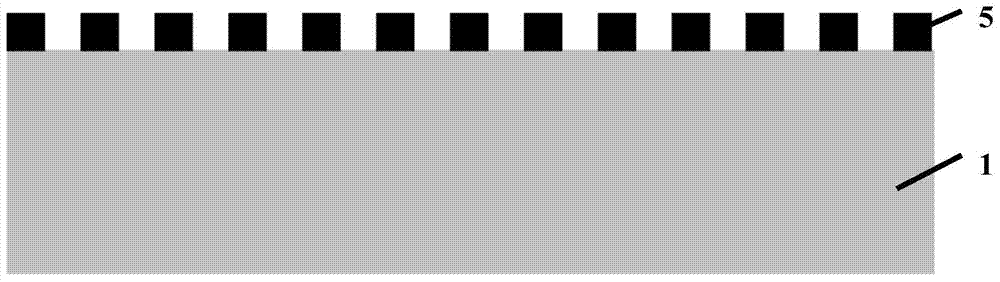

[0029] ②A 90nm aluminum layer is deposited on the side with the nano-grating pattern on the substrate by thermal evaporation, an upper aluminum nano-grating layer is formed on the embossed adhesive layer, and a lower aluminum nano-grating layer is formed on the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com