Chamber structure applied to plasma equipment and plasma equipment

A plasma and chamber technology, applied in the field of plasma, which can solve the problems of process performance, such as etching speed and etching uniformity, which cannot be precisely controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

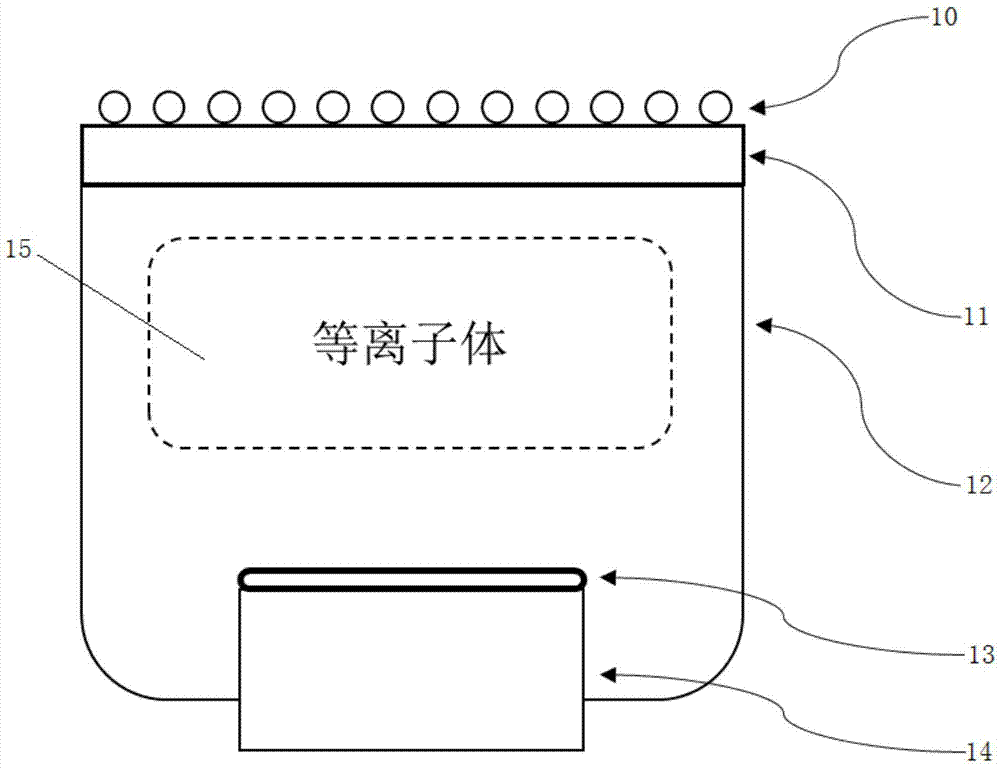

[0021] The embodiment of the present application provides a chamber structure and plasma equipment applied to plasma equipment, which can increase the density of plasma, thereby adjusting the corresponding local process performance capabilities such as etching speed, etching uniformity, etc. , to improve product quality.

[0022] The main realization principles, specific implementation modes and corresponding beneficial effects of the technical solutions of the embodiments of the present invention will be described in detail below in conjunction with each accompanying drawing.

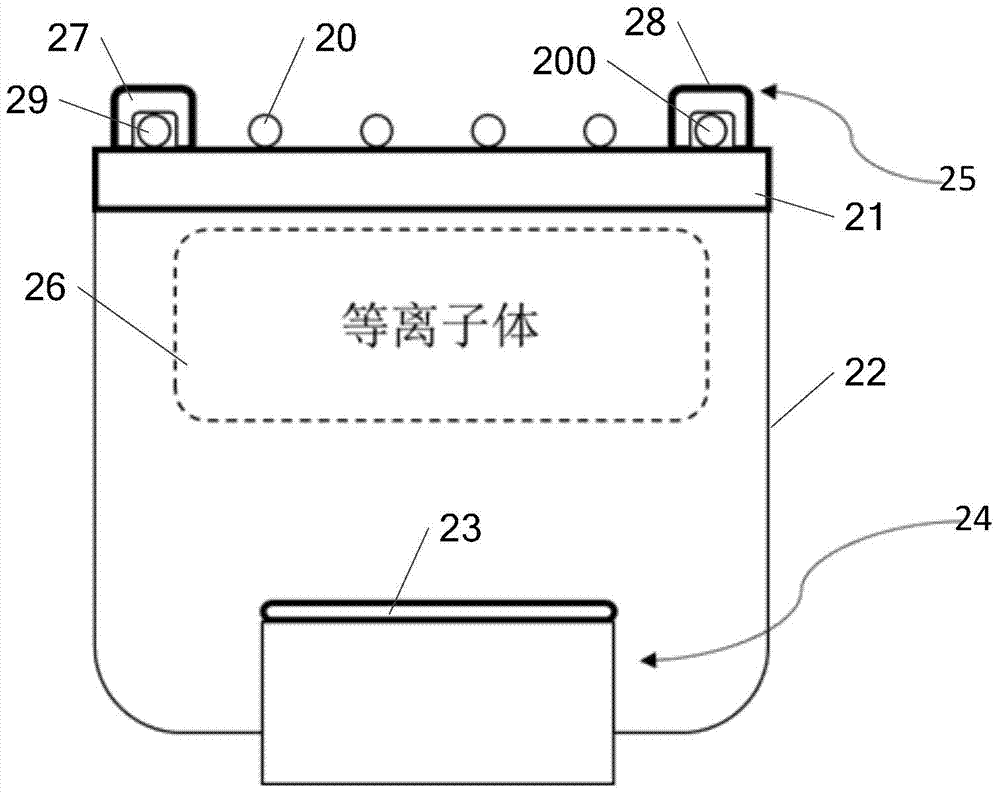

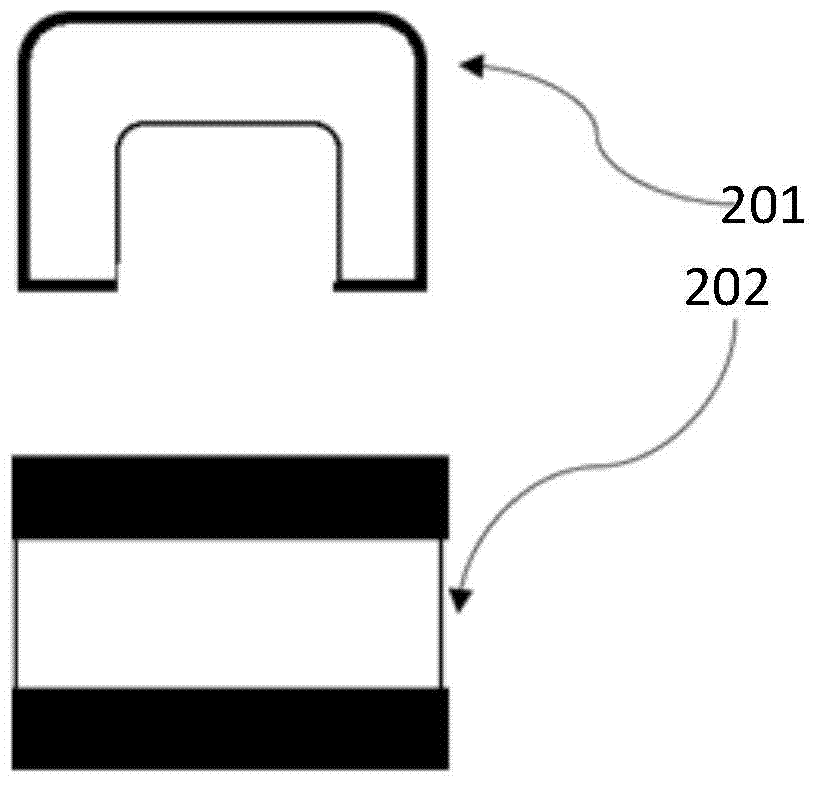

[0023] An embodiment of the present invention proposes a chamber structure applied to plasma equipment, see figure 2 , including a radio frequency coil 20, a quartz coupling window 21, a cavity 22, a substrate 23, a lower electrode 24 and a magnetizer 25, the radio frequency coil 20 is arranged on the upper part of the quartz coupling window 21, and the quartz coupling window 21 is arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com