Wirelessly powered magnetostrictive high-frequency response characteristic measuring device

A technology of wireless power supply and magnetostriction, applied in circuit devices, battery circuit devices, electromagnetic wave systems, etc., to achieve the effects of easy overheating, convenient and flexible layout, and simple and reliable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

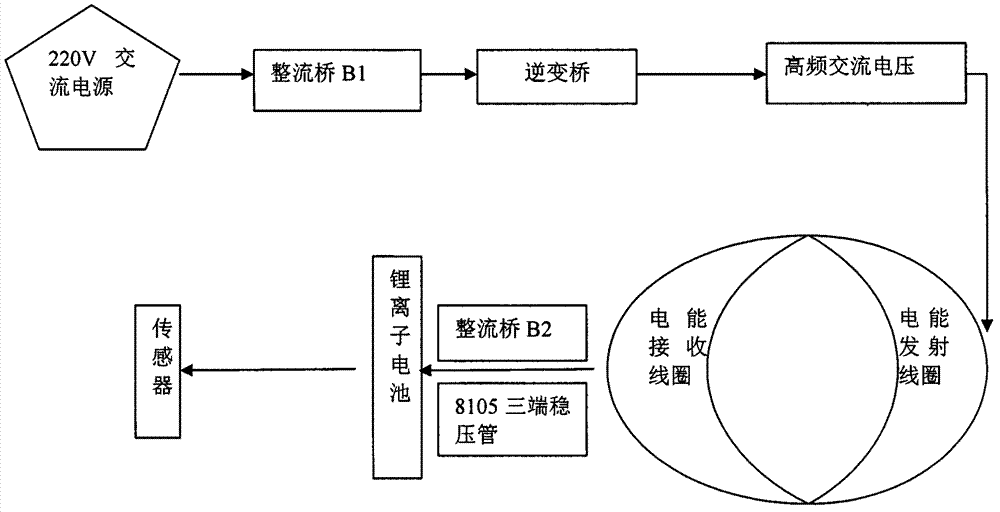

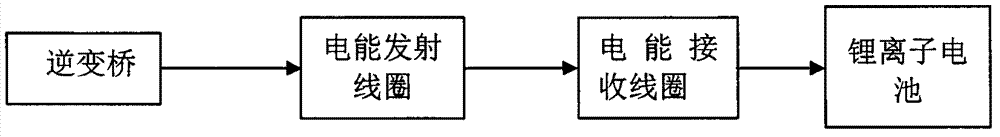

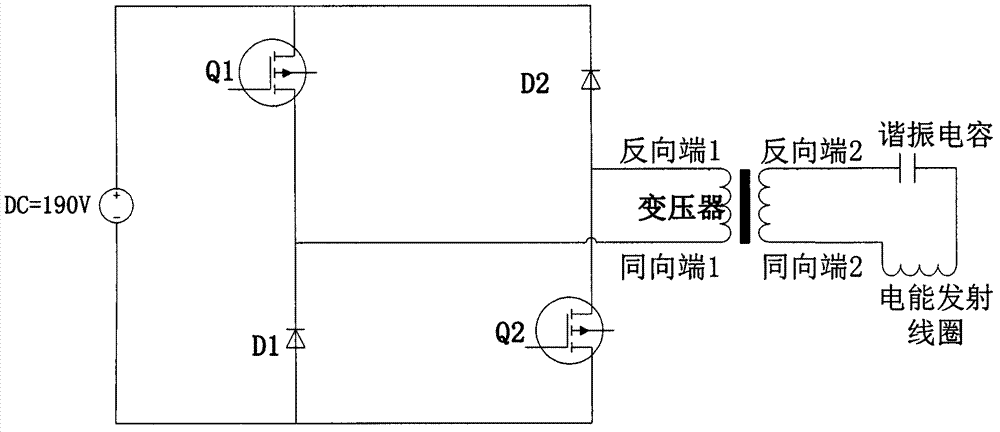

Method used

Image

Examples

Embodiment 1

[0027] When the system is working, there are two sensors, the square wave voltage output by the inverter bridge is 190V, the square wave output of the inverter bridge is continuous for 1ms, the interrupt output is 9ms, and the electric energy is output alternately. Transmitted to the power receiving coil, the distance between the power transmitting coil and the power receiving coil is 2.5m, the inductance and parasitic capacitance of the power receiving coil form the receiving system to receive power, the voltage of the single-turn coil of the receiving coil is 6.8V, 1MHz alternating current, through the rectifier bridge After rectification and 8105 three-terminal regulator voltage regulator, 5V DC is used to supply power to the lithium-ion battery.

[0028] Finally, the 5V wireless power transmission to the two sensors is realized.

Embodiment 2

[0030] Except that the number of sensors is 4, and the distance between the power transmitting coil and the power receiving coil is 1.8m, everything else is the same as that of Embodiment 1.

[0031] Finally, 5V wireless power transmission to 4 sensors is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com