An external rotor motor generator

A motor-generator, outer rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, synchronous machines, etc., can solve the problem of not finding excitation windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be described in further detail below in conjunction with the accompanying drawings.

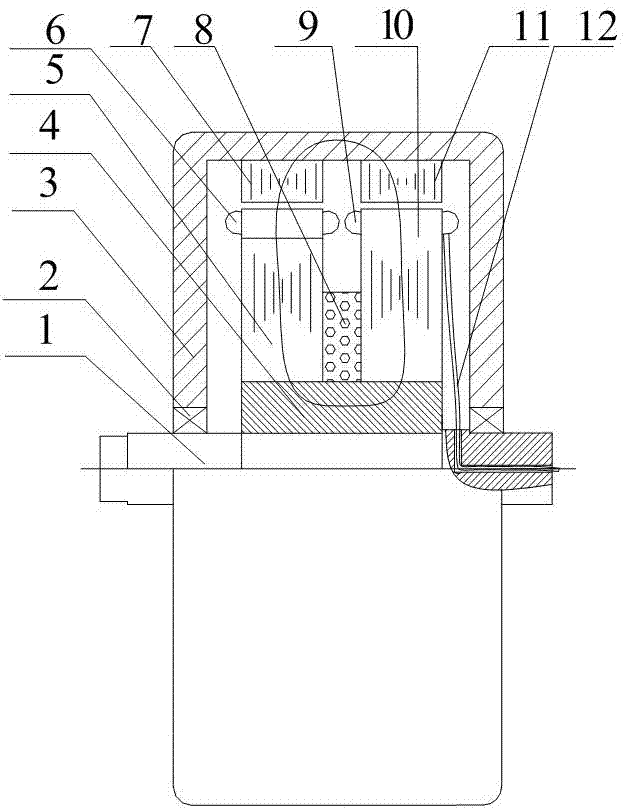

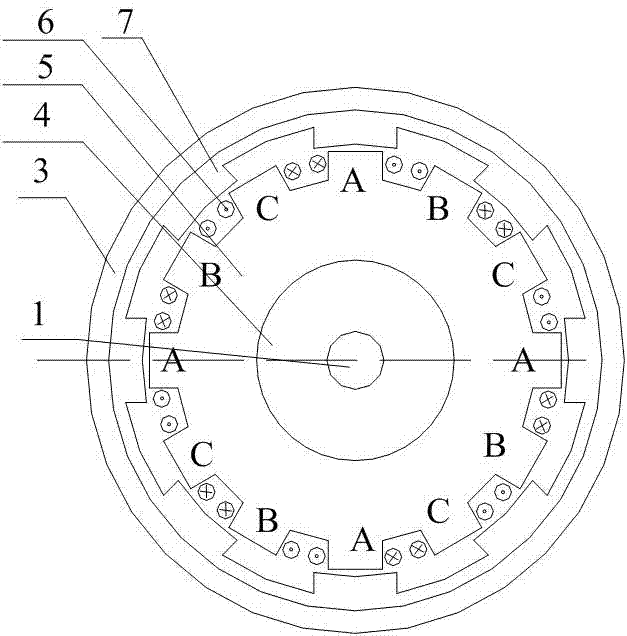

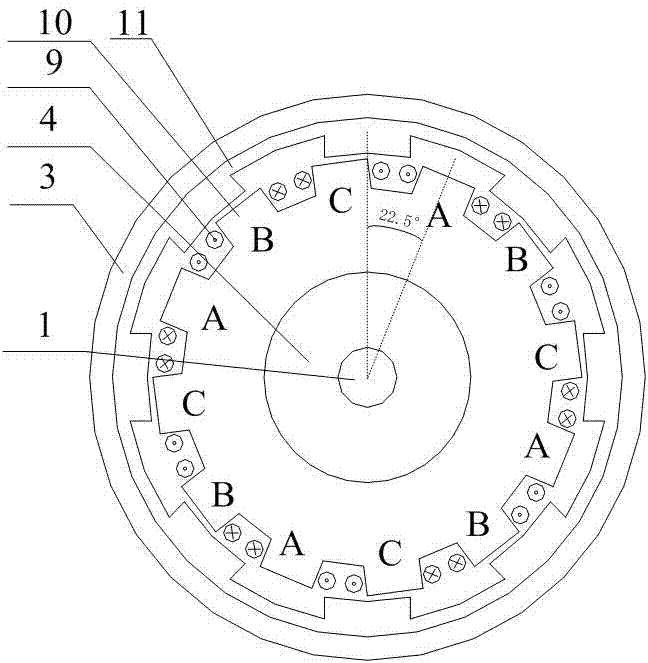

[0030] figure 1 It is a longitudinal sectional view of an outer rotor motor generator of the present invention. In this example n=3. The motor generator comprises a shaft (1), a housing (3), a stator yoke (4), an N-pole stator core (5), an S-pole stator core (10), an N-pole rotor core (7), an S-pole rotor Iron core (11), armature winding and field winding (8). The N-pole stator core (5) and the S-pole stator core (10) have pole numbers of 3n=12 and are arranged at intervals in the axial direction, and the N-pole stator core (5) and the S-pole stator core (10) are fixed on the stator yoke (4 )superior.

[0031] Between the N-pole stator core (5) and the S-pole stator core (10) is the field winding (8) wound around the stator yoke (4), and the N-pole stator core (5) can be formed by energizing the field winding (8). N pole, and the S pole stator core (10) constitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com