Patents

Literature

46results about How to "Effective complementary" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

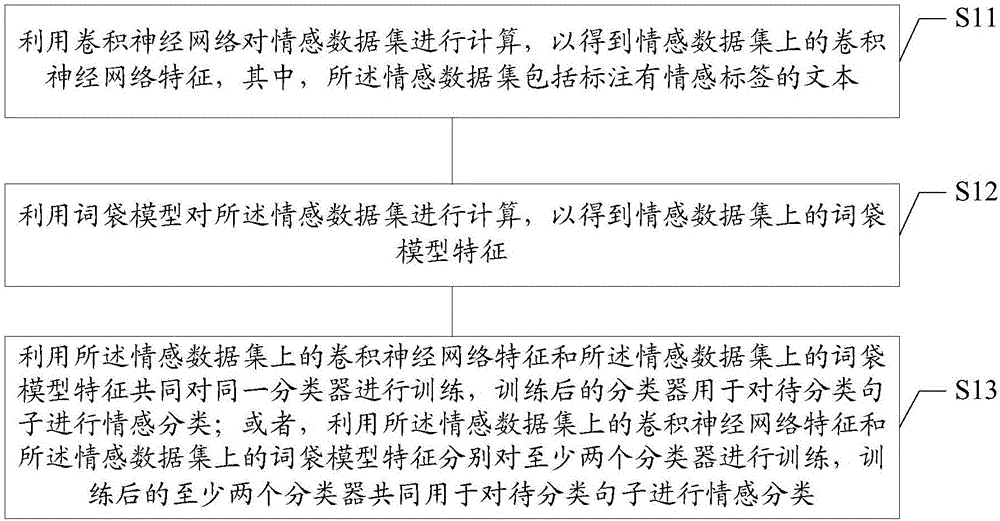

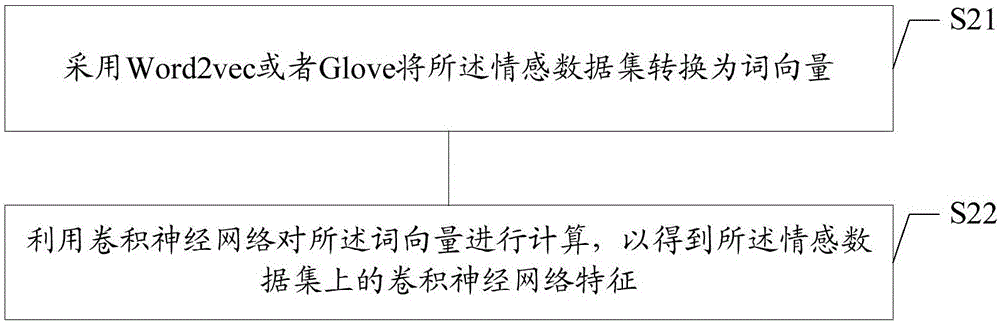

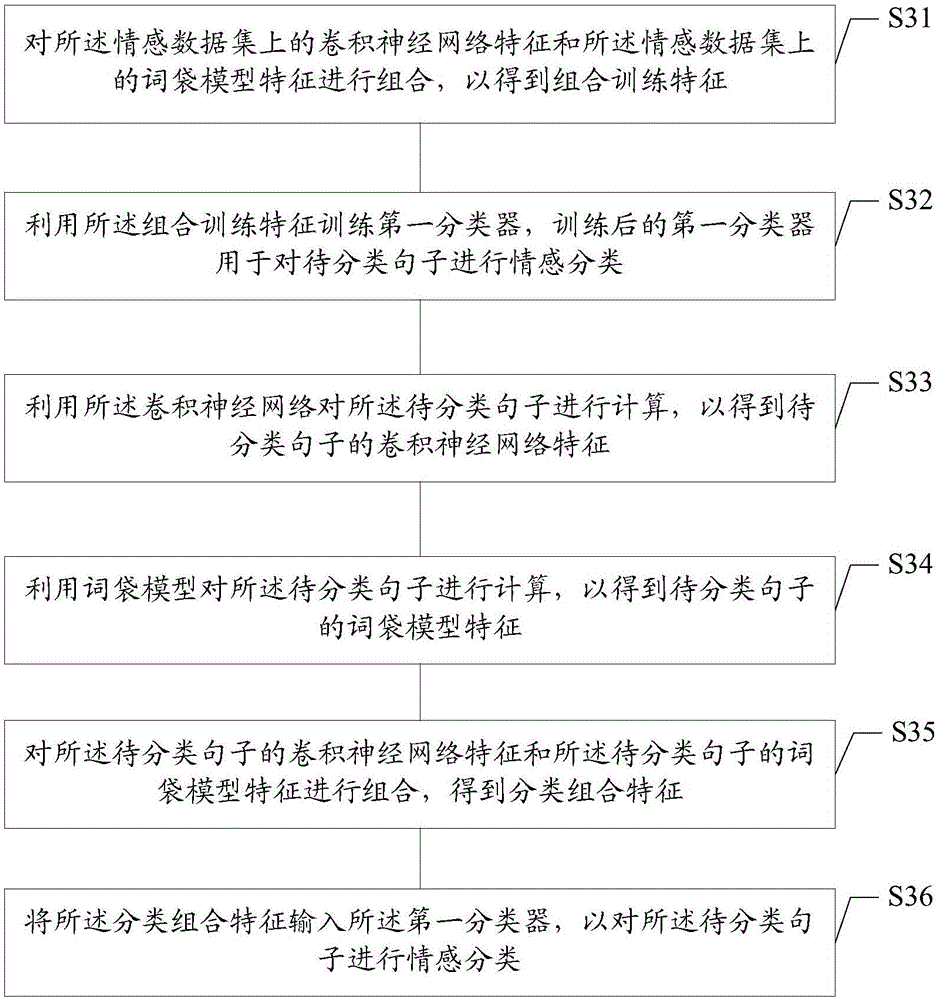

Sentiment classifying method and device

InactiveCN106445919AEffective complementaryImprove accuracyCharacter and pattern recognitionNatural language data processingData setConvolutional neural network

The invention discloses a sentiment classifying method and device. The method includes the steps that sentiment data are calculated through a convolutional neural network to obtain convolutional neural network features on a sentiment data set, wherein the sentiment data set includes texts labeled with tags; the sentiment data set is calculated through a word bag model to obtain word bag model features on the sentiment data set; a classifier is trained through the convolutional neural network features on the sentiment data set and the word bag model features on the sentiment data set, and the classifier obtained after training is used for carrying out sentiment classification on sentences to be classified; or at least two classifiers are trained through the convolutional neural network features on the sentiment data set and the word bag model features on the sentiment data set, and the two classifiers obtained after training are used for carrying out sentiment classification on the sentences to be classified. The method and device are higher in classification accuracy.

Owner:SHANGHAI XIAOI ROBOT TECH CO LTD

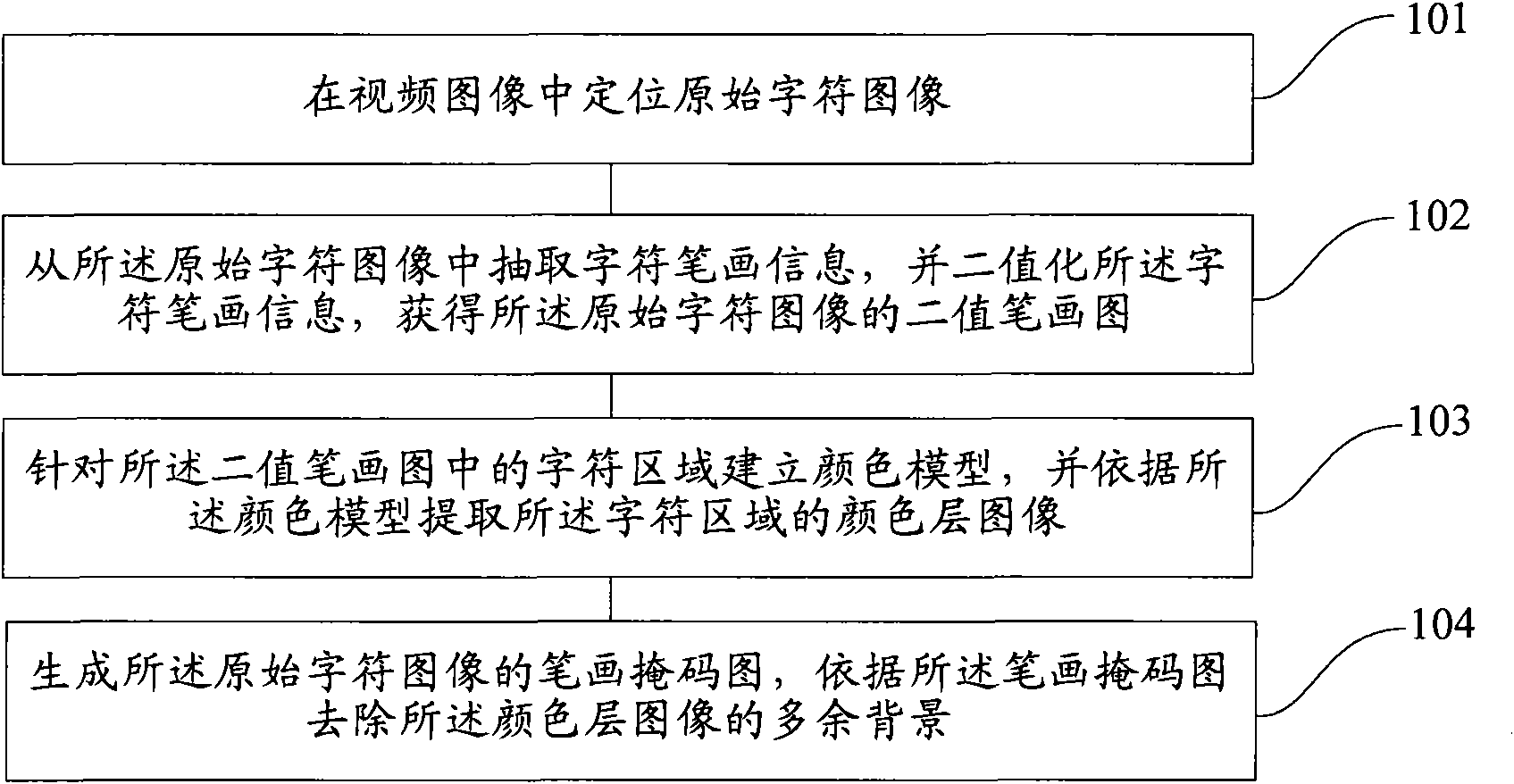

Method and device for segmenting characters from video image

InactiveCN101599124AGood character segmentationProtection from erosionCharacter and pattern recognitionColor modelAnalysis method

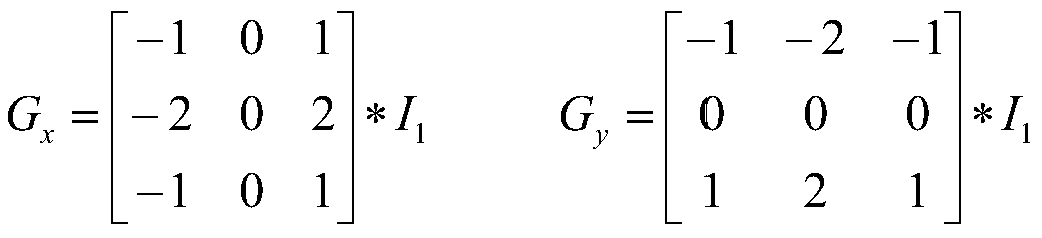

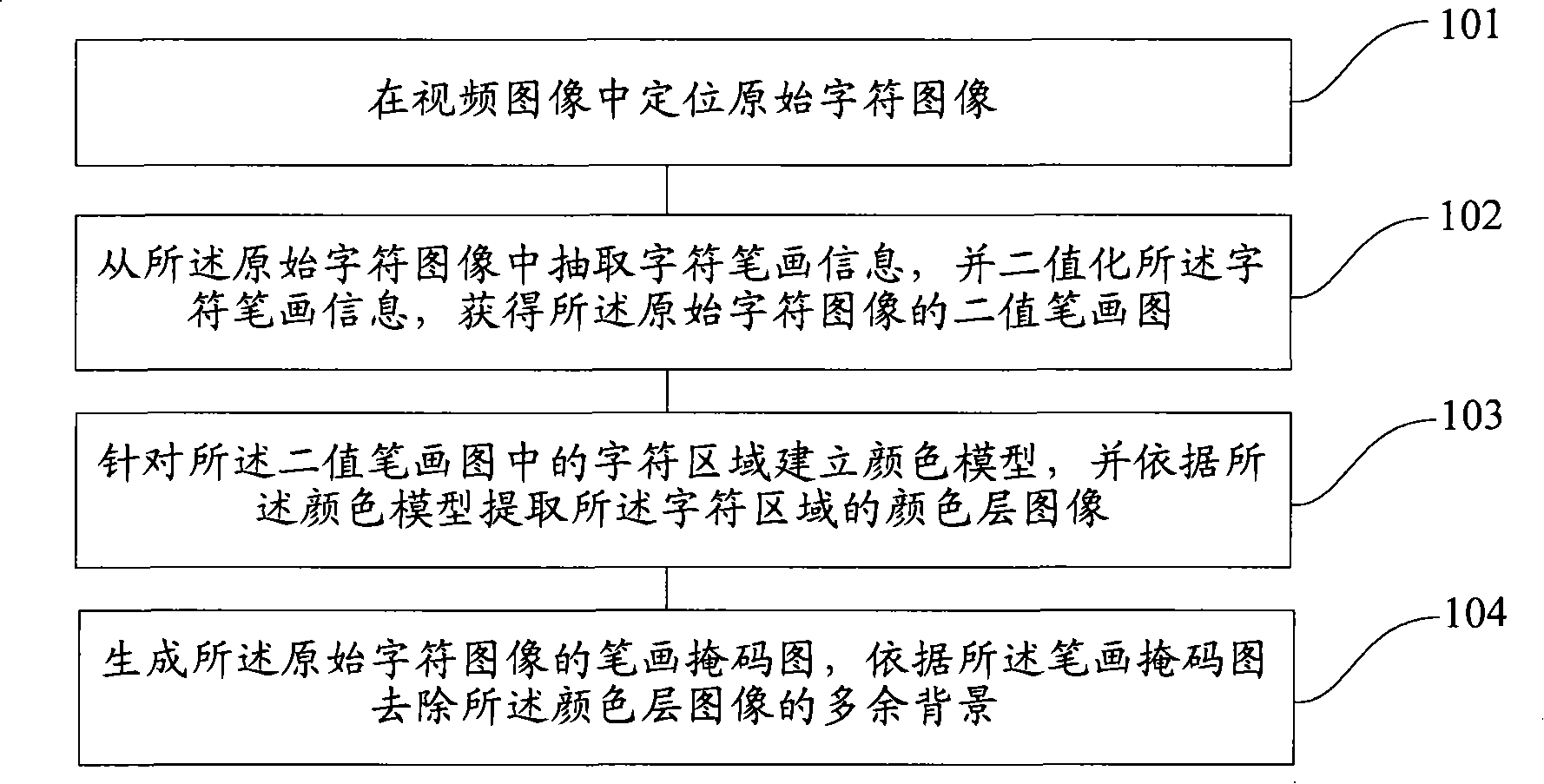

The invention discloses a method for segmenting characters form a video image, which comprises the following steps: positioning an original character image in the video image; extracting character stroke information from the original character image, obtaining a binary stroke image of the original character image according to the character stroke information; establishing a color model aiming at a character region in the binary stroke image, extracting a color layer image of the character region according to the color model; and removing excess backgrounds and noise by using an improved connection body analysis method with stroke masks so as to obtain the target character image. The invention has little computation and good property and can rapidly and accurately segment the characters from the video image of the complex backgrounds without machine learning.

Owner:HANVON CORP

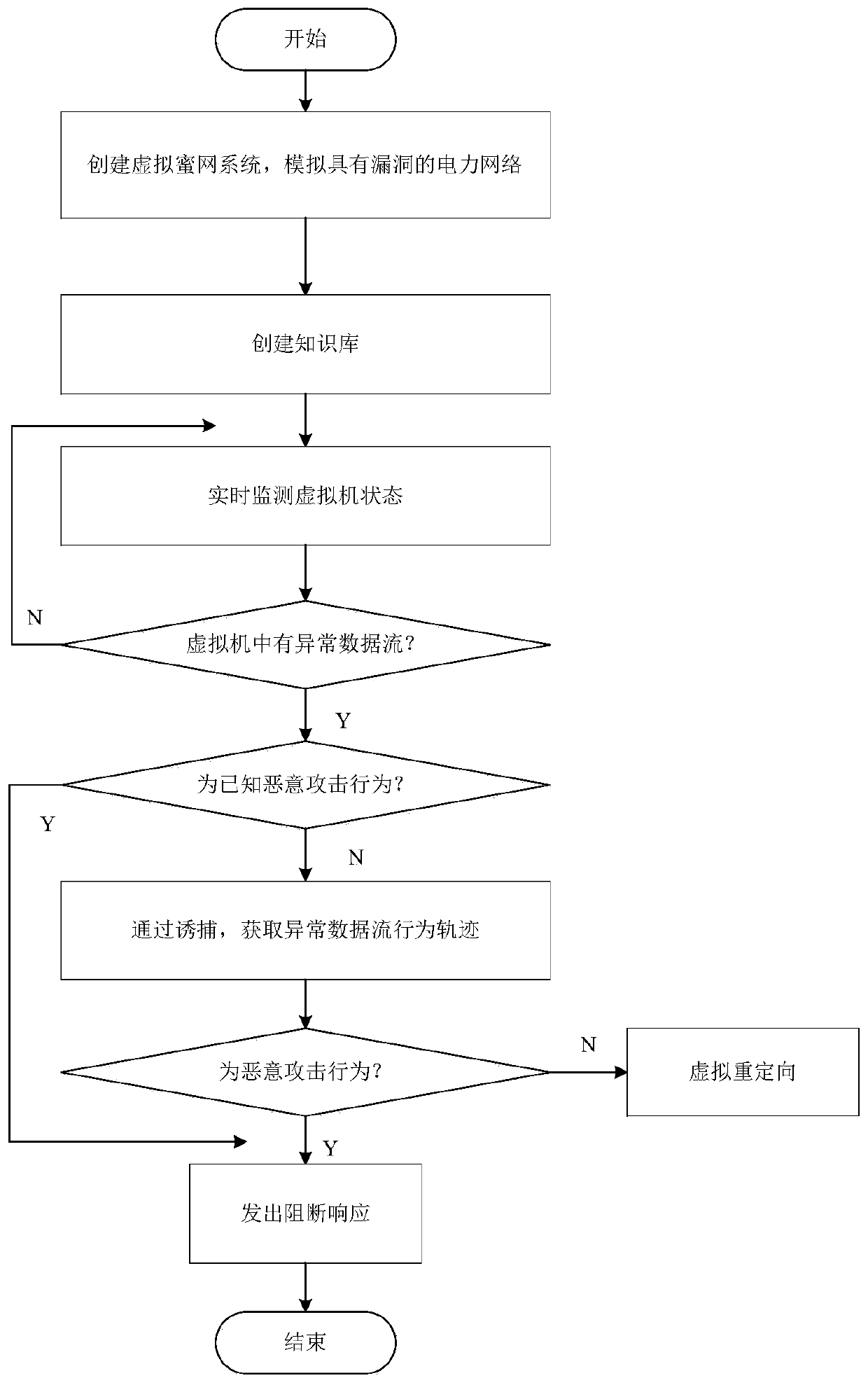

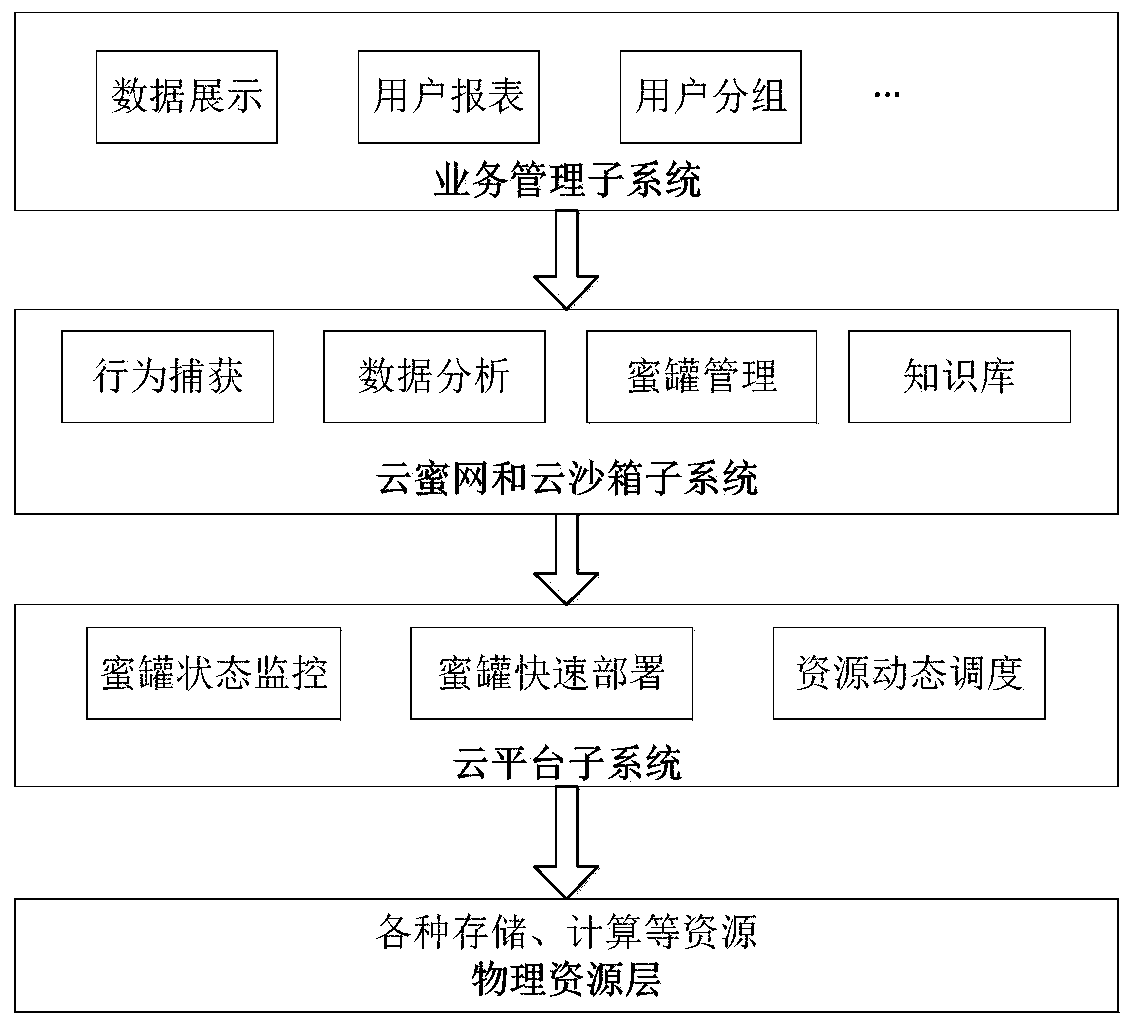

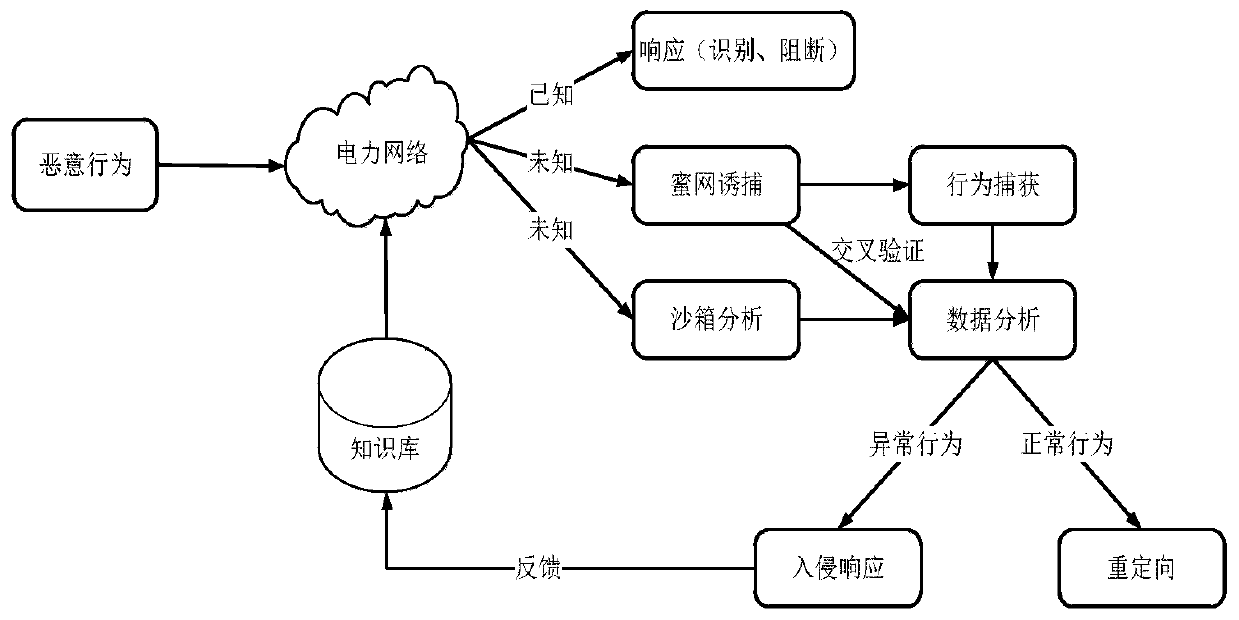

Power monitoring active defense method and system based on virtualization dynamic deployment

InactiveCN110784476AImprove securityReduce the likelihood of being detectedTransmissionVirtualizationData stream

The invention relates to a power monitoring active defense method and system based on virtualization dynamic deployment, and the method comprises the steps: (1), building a virtual honeynet system, and simulating a real business system of a power network; (2) monitoring the state of the virtual machine in real time, and carrying out honeynet trapping to obtain an abnormal behavior track when an abnormal data flow is monitored; and (3) analyzing whether the behavior is a malicious attack behavior or not, and carrying out blocking response. The active defense system adopting the honeypot and sandbox technology can reduce the possibility that a real service network of the power system is detected, increase the attack cost difficulty and timeliness of attackers, and effectively complement passive protection measures existing in the power system.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

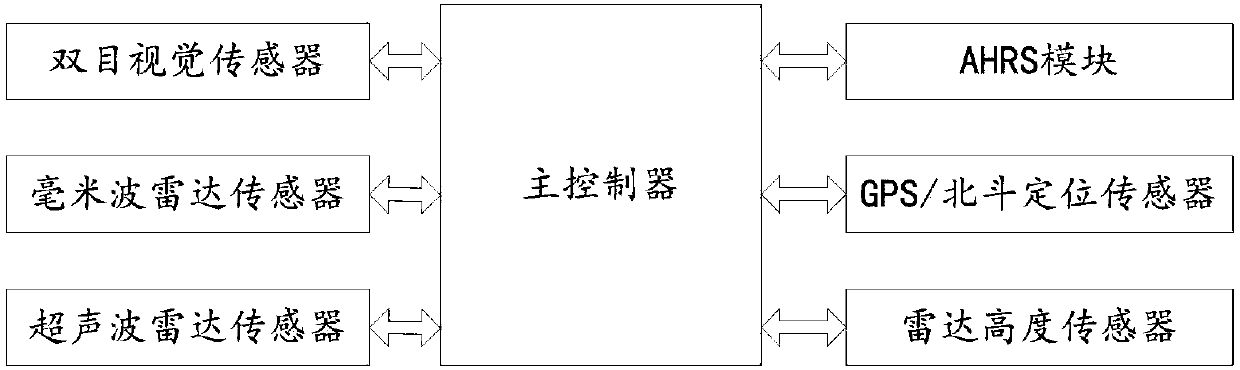

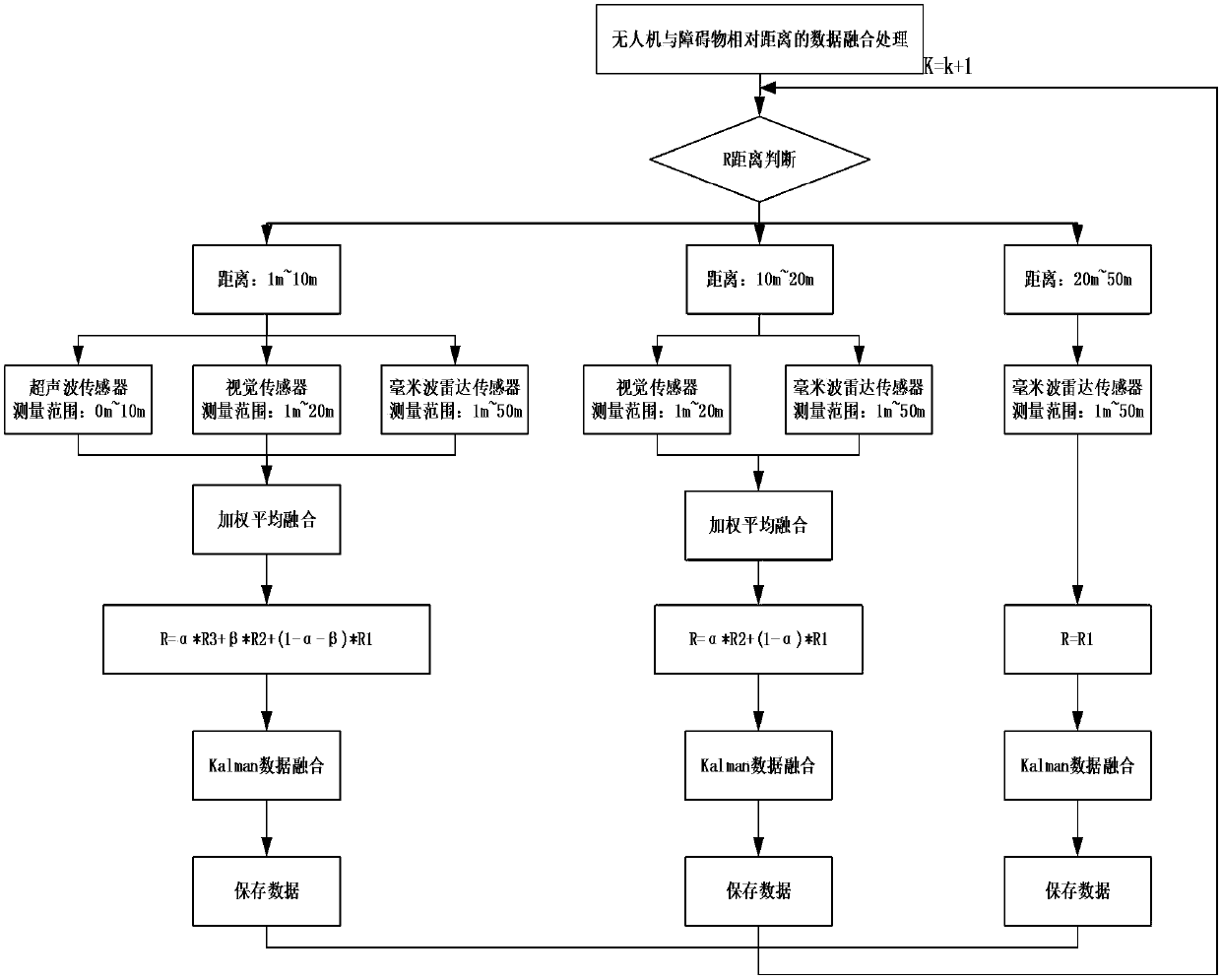

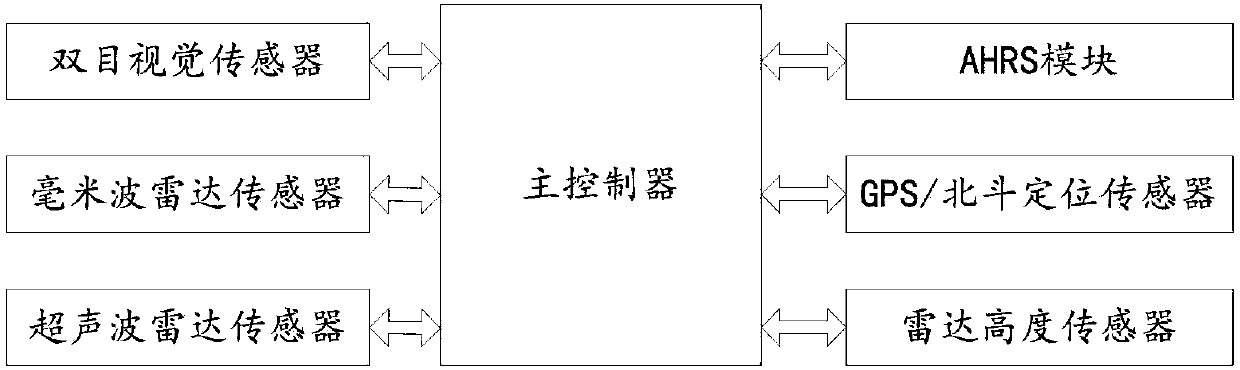

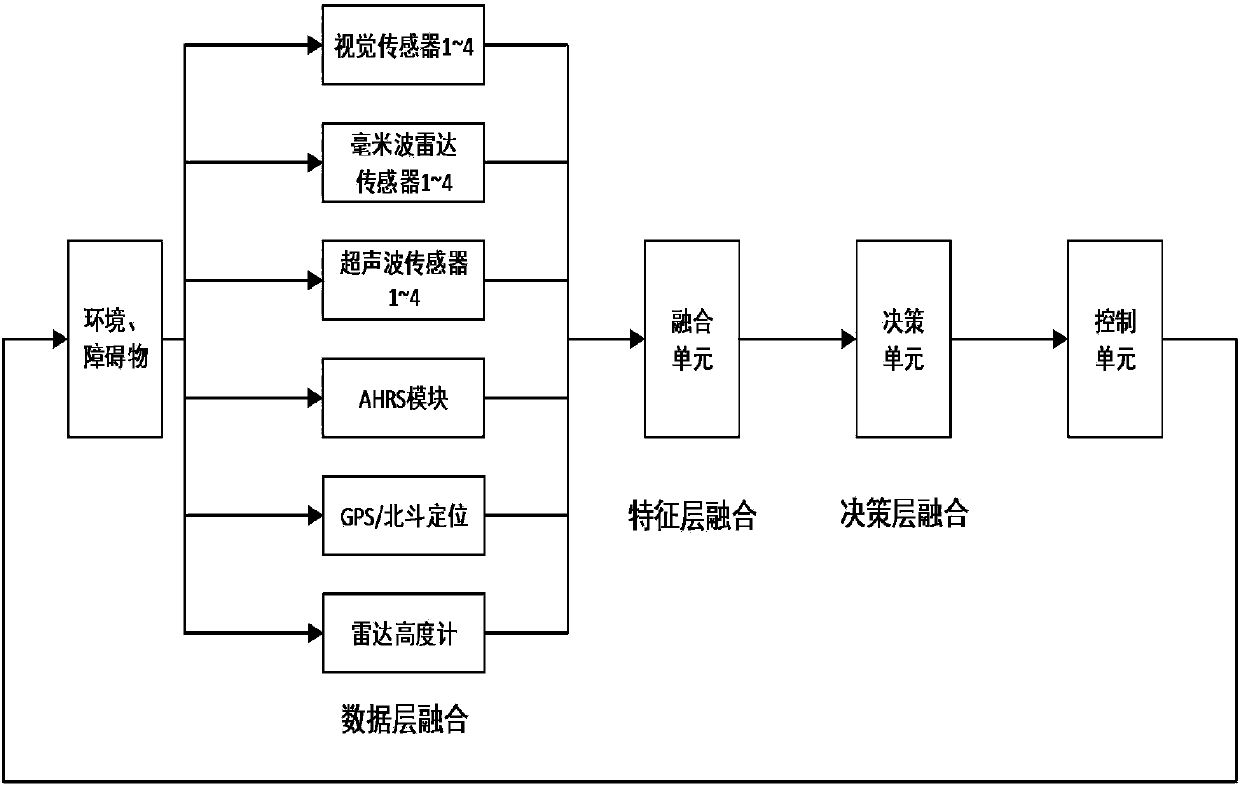

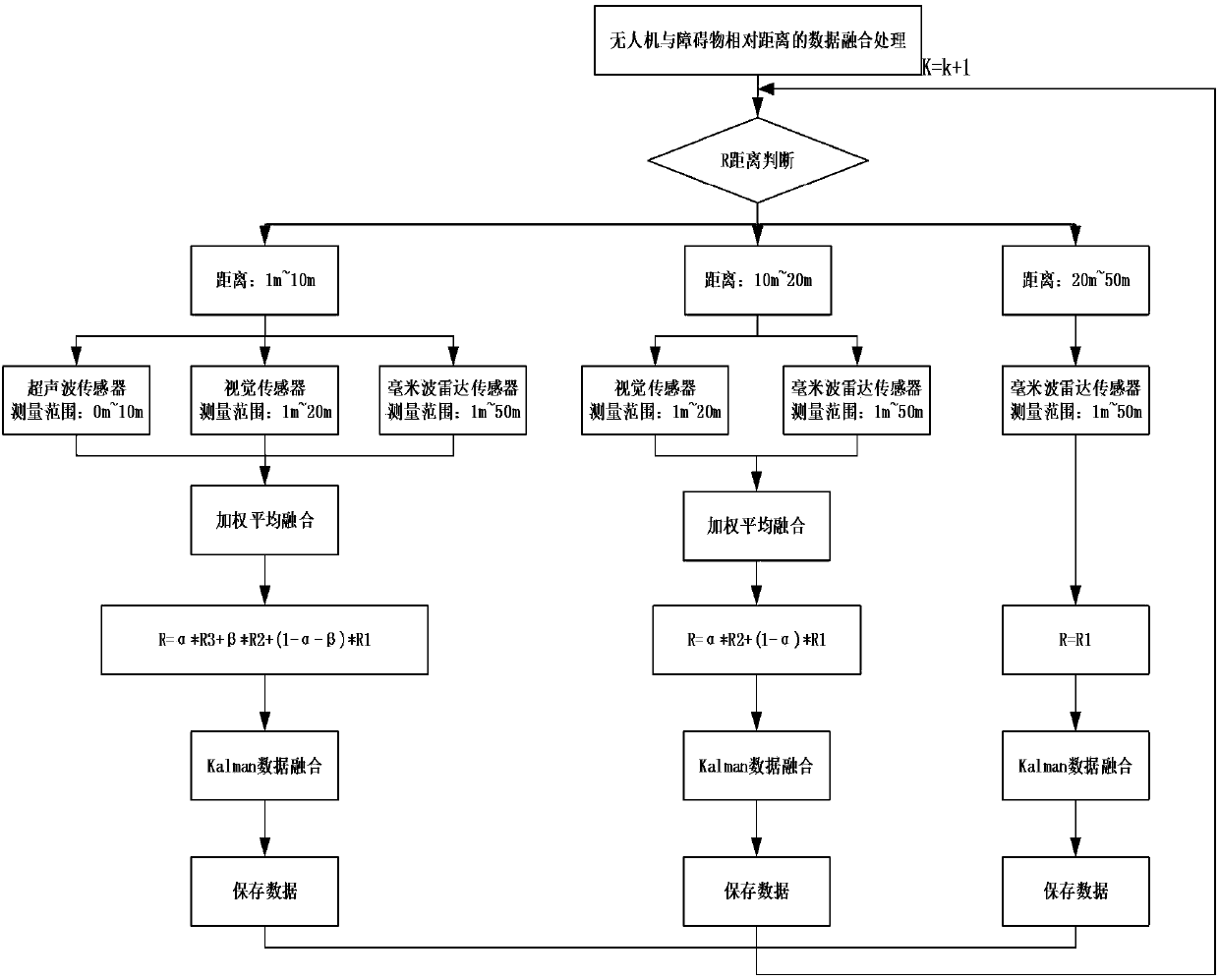

Unmanned plane and barrier data fusion method

ActiveCN107783106AEliminate redundancyEliminate contradictionsScene recognitionRadio wave reradiation/reflectionRadarLocal environment

The invention relates to an unmanned plane and barrier data fusion method. The method is characterized by comprising steps that data acquired by each sensor is processed by a data fusion layer; millimeter wave radar sensor output data is a relative distance R1 between an unmanned plane and a barrier, the relatively speed V1 and angles between the barrier and a radar normal, and an azimuth theta1 and a pitch angle psi1 are comprised; a relative distance R2 between the unmanned plane and the barrier is inputted by an ultrasonic radar sensor; an object area S, an azimuth theta2 and a relative distance R3 are outputted by a binocular vision sensor; and a height value R4 between the unmanned plane and the ground is outputted by a radar height sensor. The method is advantaged in that incompletedata of local environments provided by same or different types of sensors at different positions are fused, possible redundancy among the sensors and contradiction data are eliminated, complementationis carried out, and uncertainty is reduced.

Owner:DALIAN ROILAND SCI & TECH CO LTD

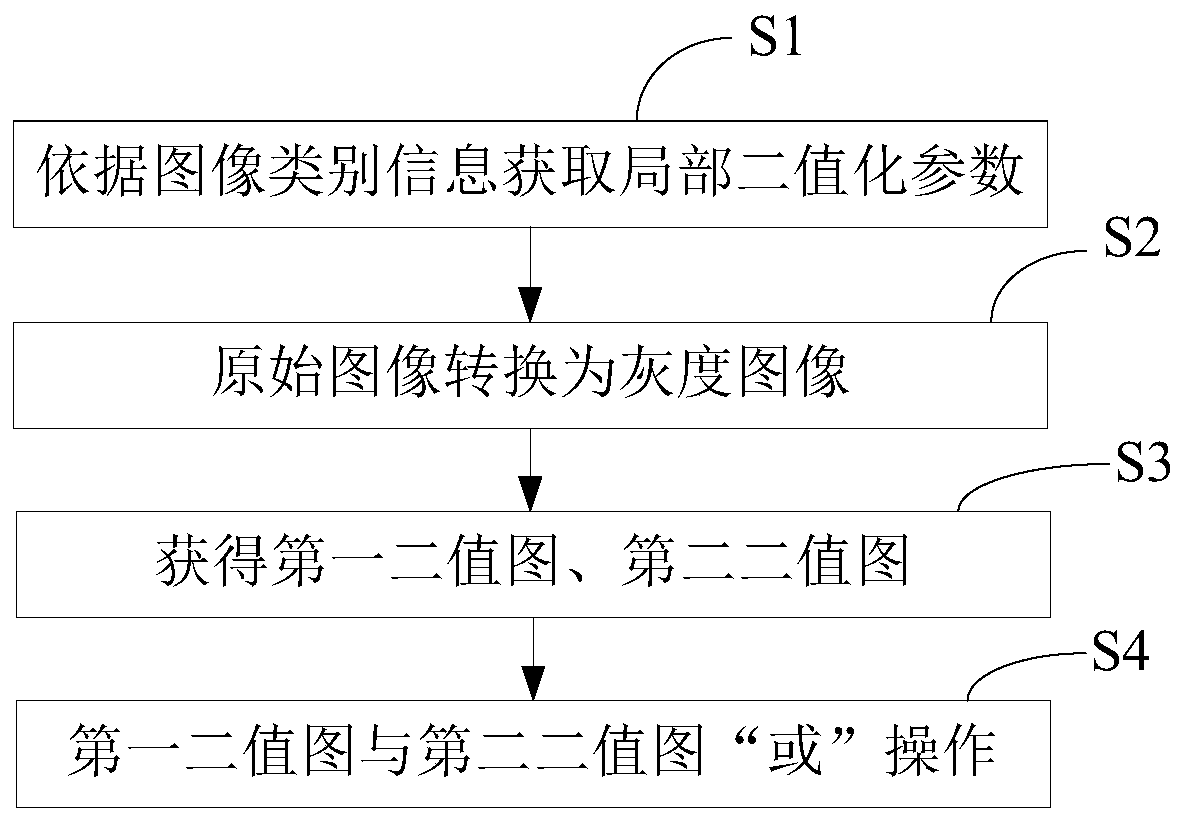

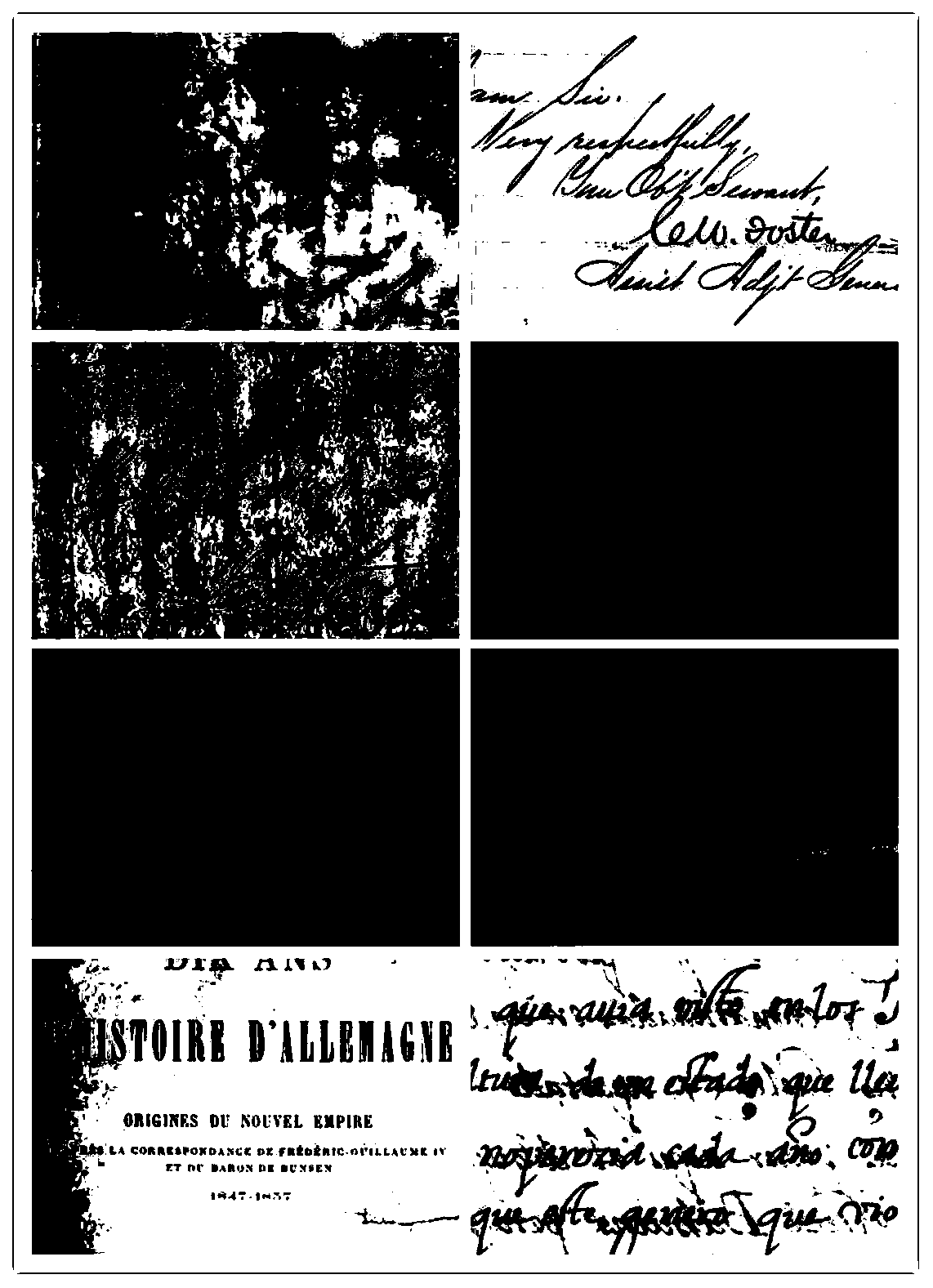

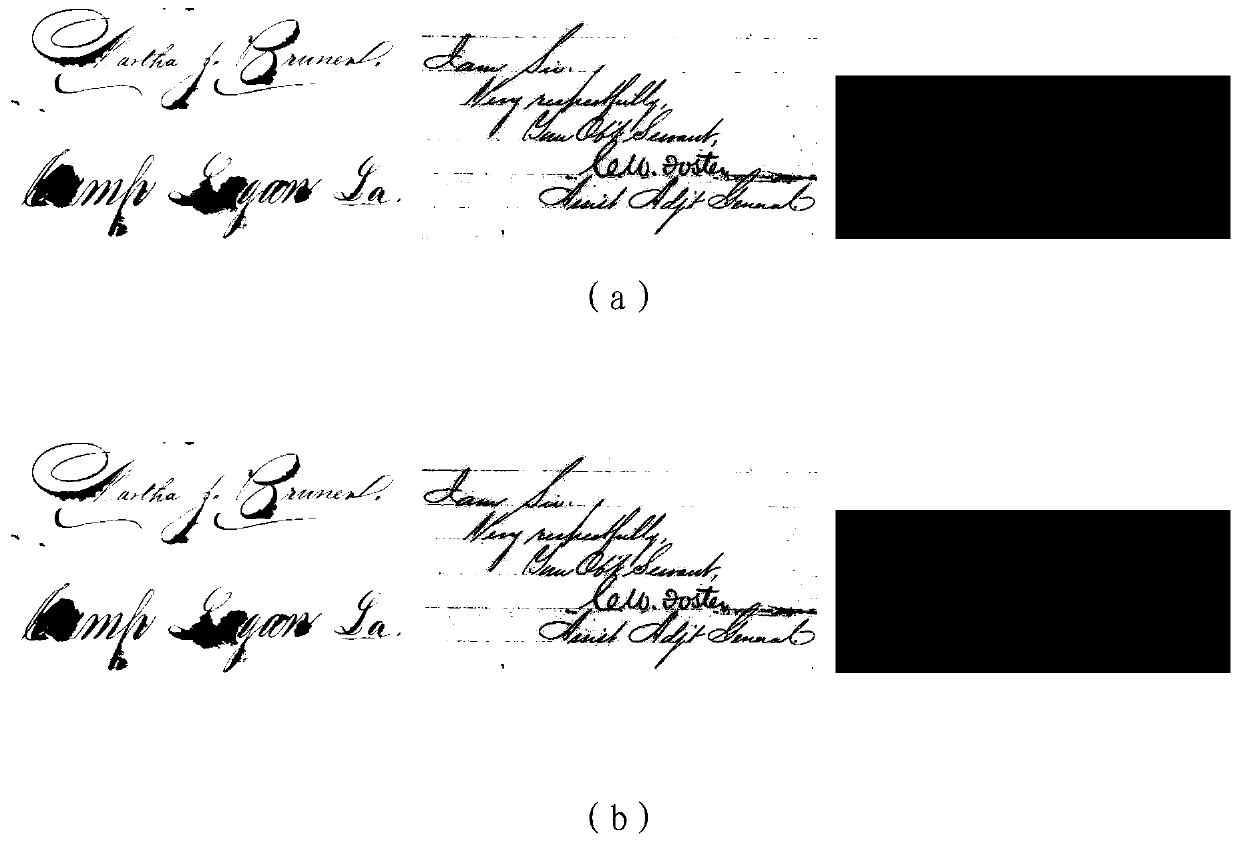

Complex background text image extraction method and system based on multi-threshold fusion

ActiveCN110008954ABinarization worksMake up for lost defectsCharacter and pattern recognitionImage extractionNoise removal

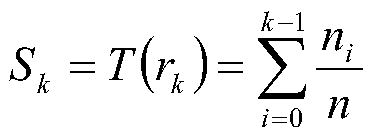

The invention discloses a complex background text image extraction method and system based on multi-threshold fusion. The method comprises the following steps: S1, acquiring an original image, and acquiring a local binarization parameter according to image category information; S2, converting the original image into a grayscale image; S3, obtaining an edge-based first binary image of the grayscaleimage by using a first processing algorithm; performing local binarization processing on the grayscale image based on the local binarization parameter by using a second processing algorithm to obtaina second binary image; and S4, carrying out logic OR operation on the first binary image and the second binary image, outputting the two images, and extracting the text image. The first binary imagebased on the edge and a second binary image obtained by local binarization processing are fused, a defect that foreground characters are lost due to noise removal in the second binary image is effectively overcome, and the local binarization parameters are set according to the category of the to-be-processed image, so that the processing effect on the characters with shallow strokes is very excellent, and the quality of the binarized image is improved.

Owner:CHONGQING UNIV

Ultrasonic testing process of marine steel-welding joint phased array

InactiveCN101832973ALow costHigh speedAnalysing solids using sonic/ultrasonic/infrasonic wavesAviationPhased array

The invention relates to an ultrasonic detecting process of a marine steel-welding joint phased array, which is characterized by comprising the following steps of: a, preparing detecting equipment; b, removing splashes, rust and oil dirt on the surface of a detected object and in a probe moving zone and smearing coupling agents on the surface of the detected object and the probe moving zone; c, selecting a reflecting angle and a transmitting depth for scanning; d, inputting data or scanned images after scanning; e, analyzing scanned zones according to the detecting data or the scanned images; and f, evaluating the quality of welding joints. The invention can carry out no-damage welding joint detection and achieve the purpose of higher speed, precision, resolution and reliability than those of the prior art and fills the blank of the research application of a phased array technique in national marine industry; besides, the invention can be directly applied to the quality detection of submarine shells and aircraft engines for missiles, makes up the shortages of the traditional ultrasonic detection or forms the effective complementation with other detecting techniques and can ensure that the quality detecting process of a product tends to be more perfect, thereby enhancing the reliability of the product detecting technique.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

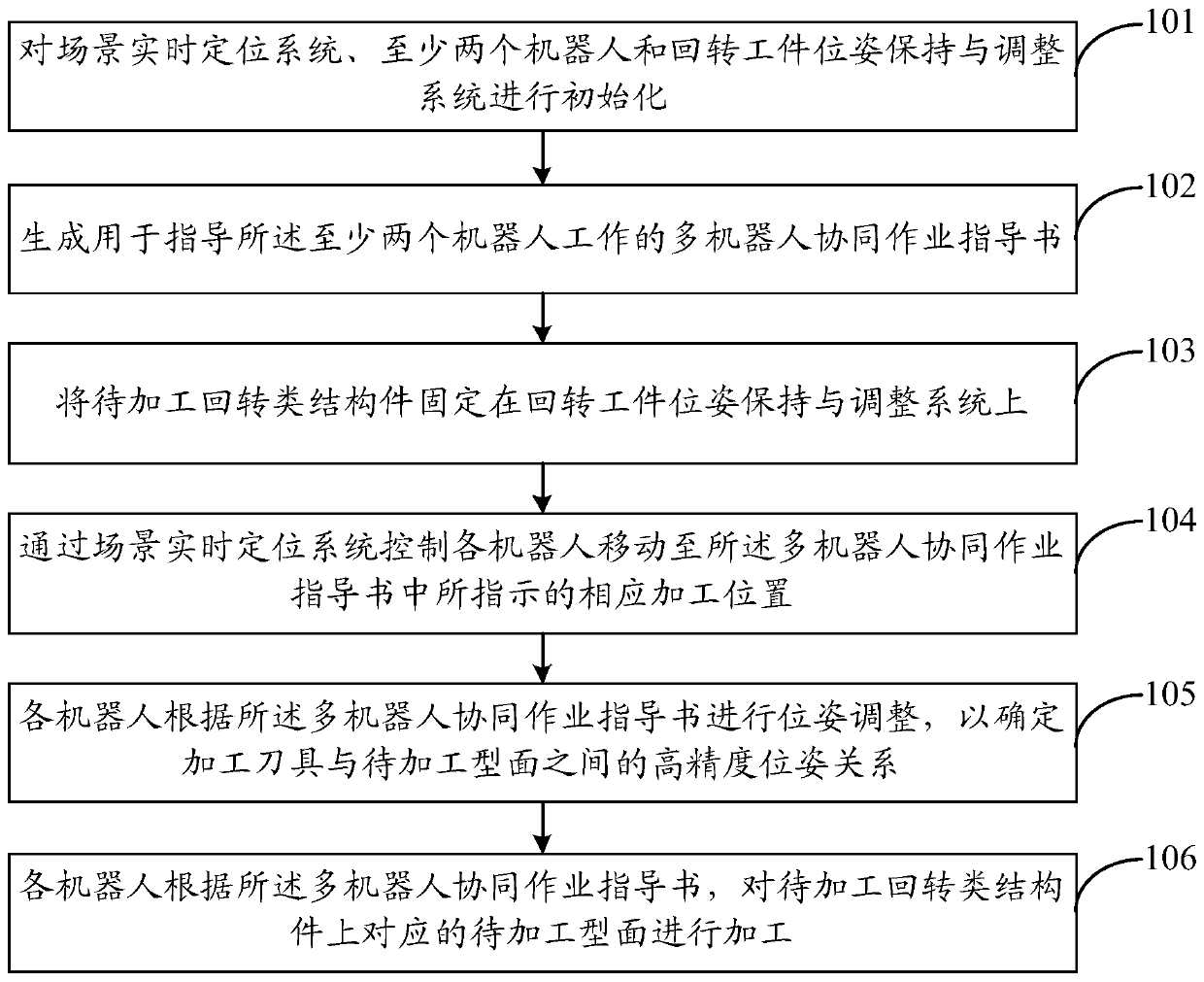

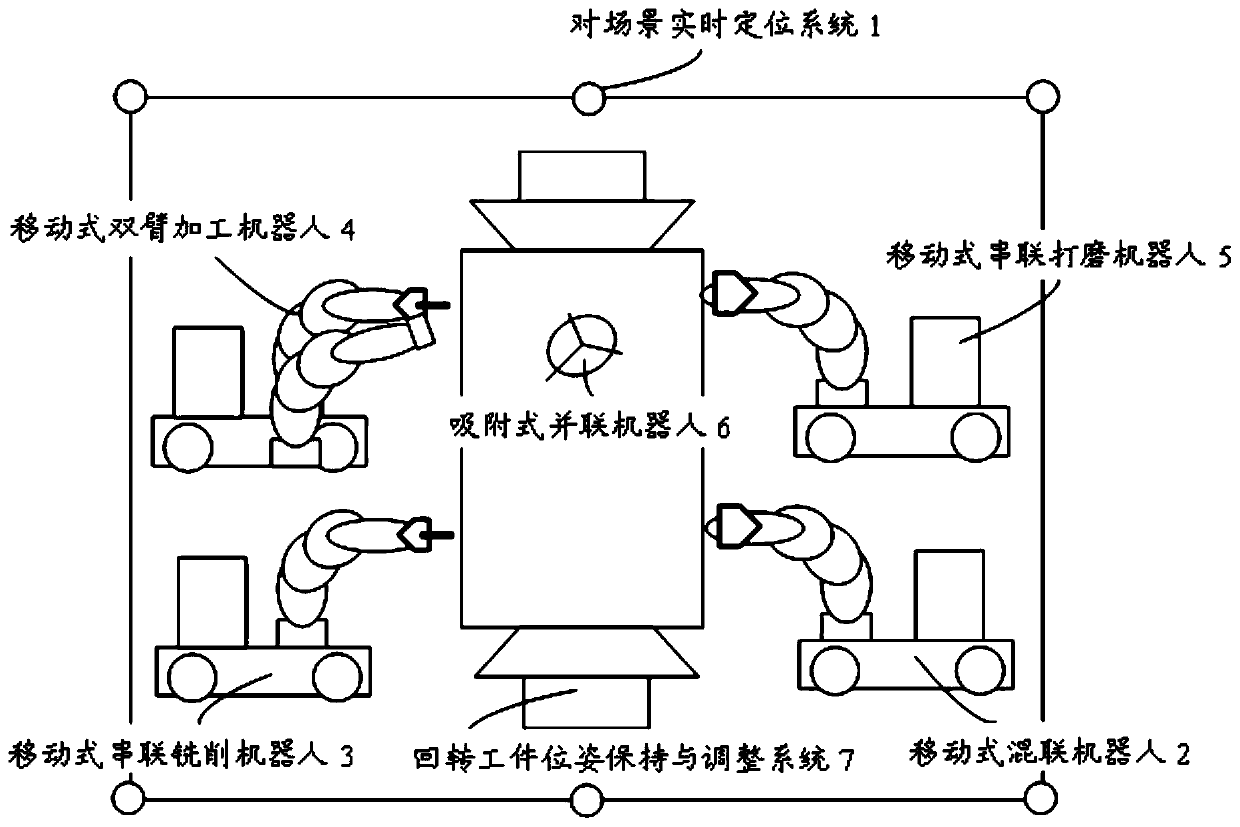

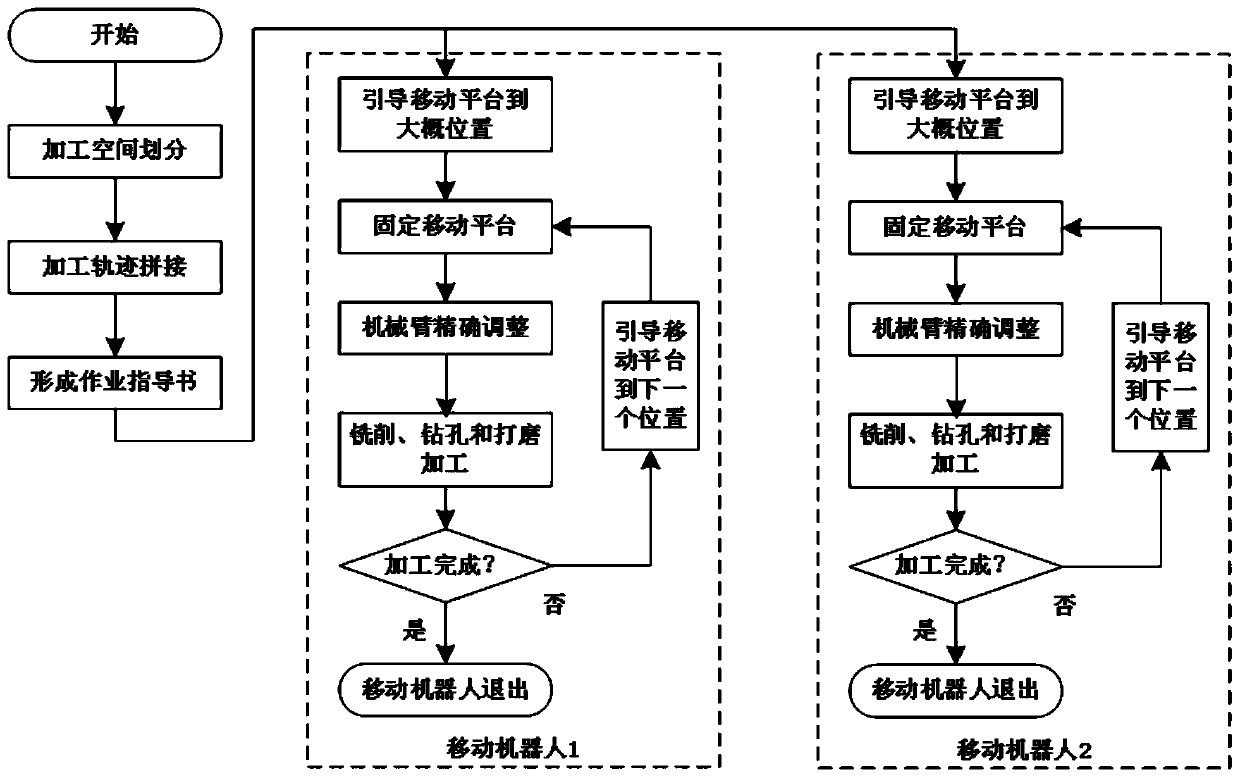

Multi-robot machining method for rotary structural part

ActiveCN109849019AIncrease the level of automationImprove processing efficiencyProgramme-controlled manipulatorGripping headsRobot machiningEngineering

The invention discloses a multi-robot machining method for a rotary structural part. The multi-robot machining method for the rotary structural part comprises the following steps: initializing a real-time scene location system, at least two robots, and a rotary workpiece position-posture keeping and adjustment system; generating multi-robot collaborative operation instruction; fixing the rotary structural part to be machined to the rotary workpiece position-posture keeping and adjustment system; controlling the robots to move to corresponding machining positions through the real-time scene location system; carrying out position-posture adjustment by the robots according to the multi-robot collaborative operation instruction to determine a high-accuracy position-posture relationship betweena machining tool and profiles to be machined; and machining the corresponding profiles to be machined on the rotary structural part to be machined by the robots according to the multi-robot collaborative operation instruction. Through the multi-robot machining method for the rotary structural part, parallel milling, drilling and grinding for a plurality of machining surfaces on a large rotary structure are realized; and due to a parallel operation method, the automation level and the machining efficiency of the large rotary structure can be effectively increased.

Owner:BEIJING SATELLITE MFG FACTORY +1

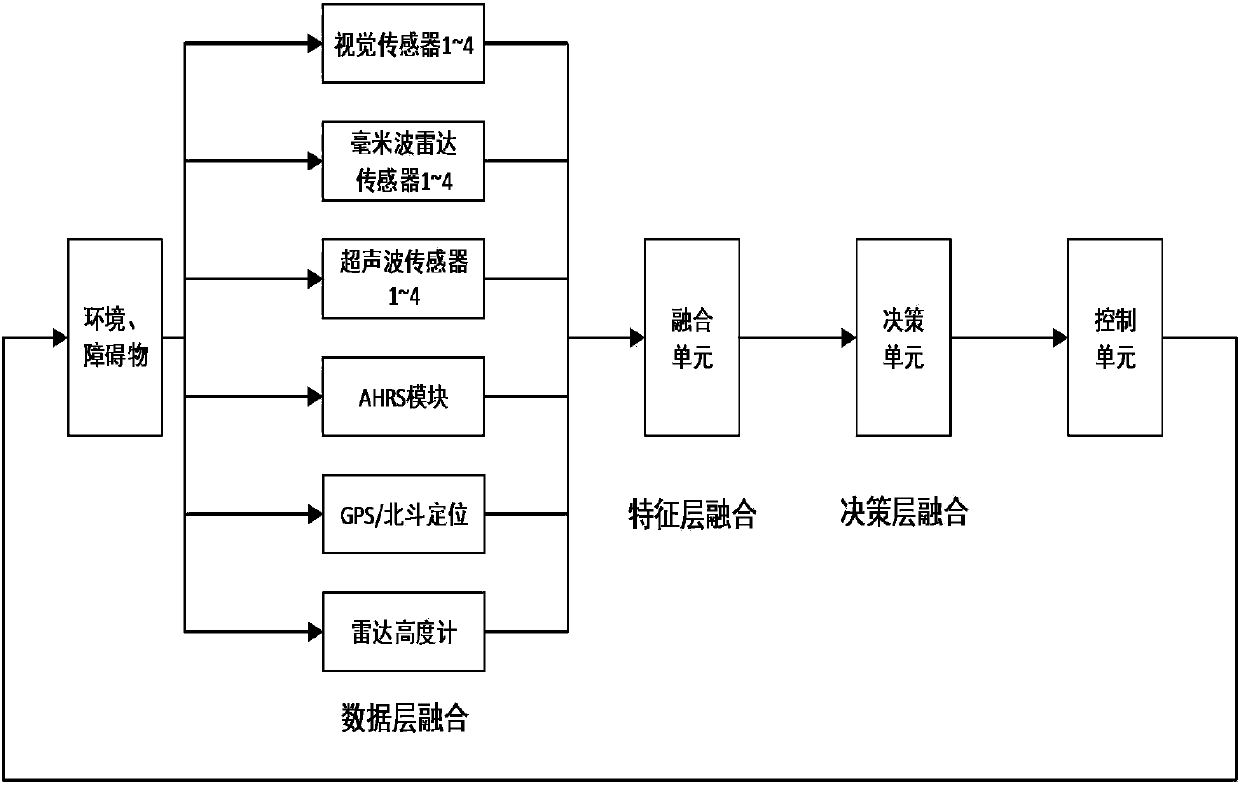

Decision fusion method applied to obstacle avoidance system

InactiveCN107783119AEliminate redundancyEliminate contradictionsRadio wave reradiation/reflectionData informationDecision taking

The invention relates to a decision fusion method applied to an obstacle avoidance system. The method comprises steps that P1, firstly, the relative distance between an unmanned plane and an obstacleis determined, and the relative distance is divided into three parts which are in three ranges of being smaller than N1m, between N1m and N2m and between N2m and N3m; P2, secondly, after distance division, dangerous grade division is carried out according to the relative speed between the unmanned plane and the obstacle; P3, a height value between the unmanned plane and the ground is determined, and grade division of the height value H is carried out; P4, for the dangerous grade, step P3 operation is needed to carry out; for the alarm grade, step P3 operation after emergent speed reduction isneeded to carry out; for the prompting grade and the irrelevant grade, third-step determination is not needed, and the process returns for re-detection. The method is advantaged in that the more accurate obstacle data information is acquired, and more accurate obstacle avoidance decision and obstacle avoidance control can be carried out.

Owner:DALIAN ROILAND SCI & TECH CO LTD

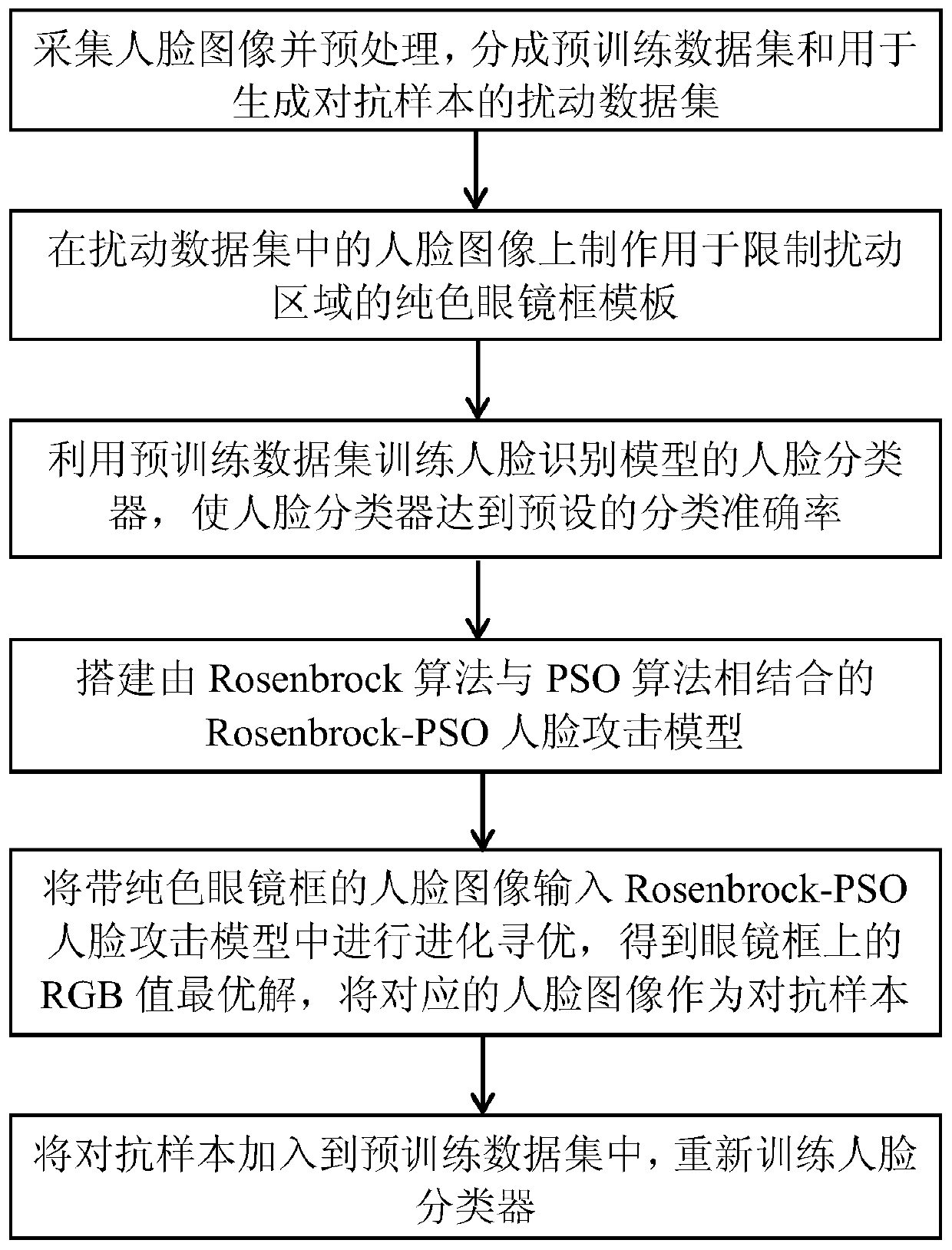

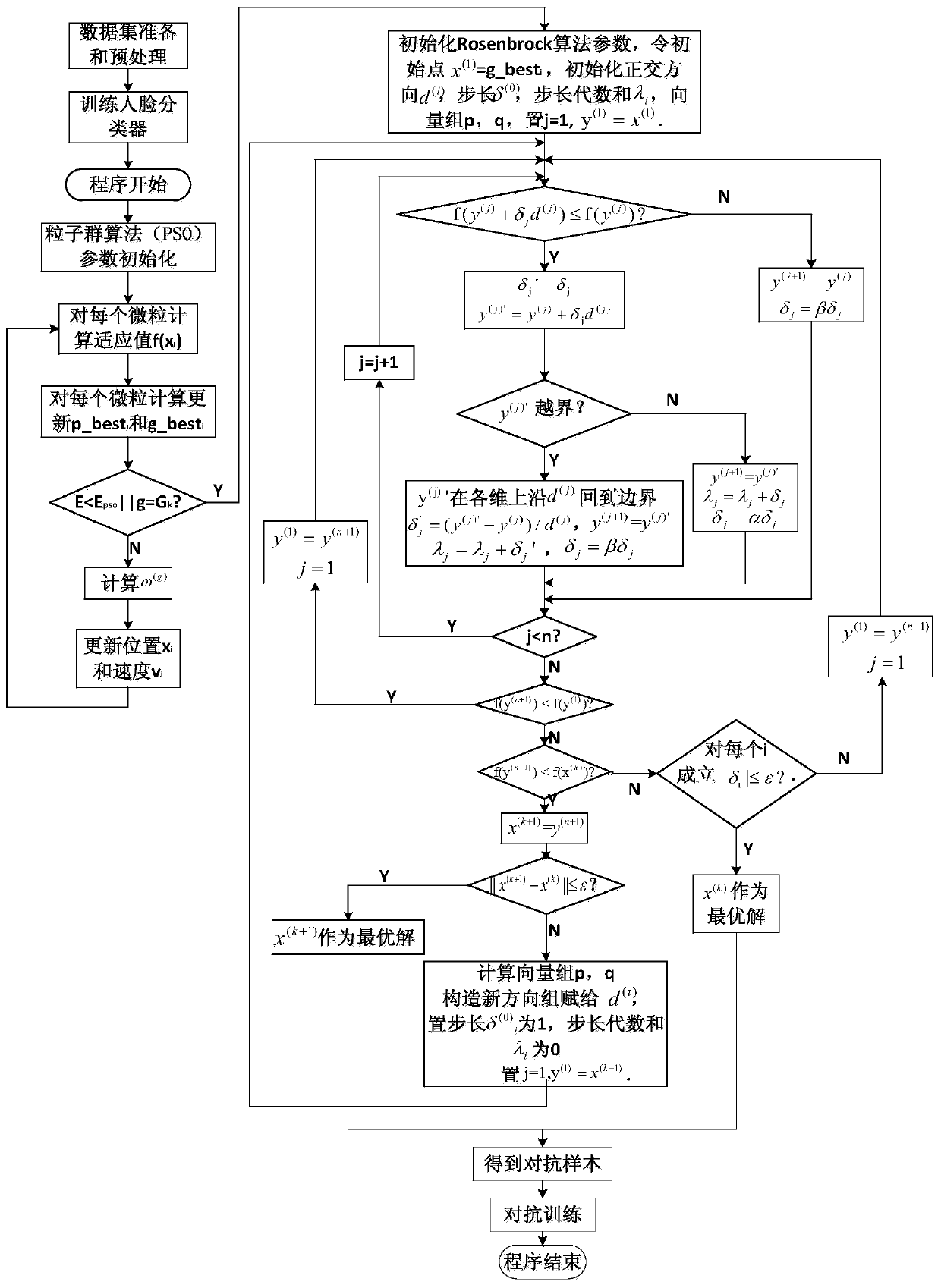

Face recognition attack defense method based on Rosenbrock-PSO

ActiveCN109858368ASave time and costReduce distortionCharacter and pattern recognitionPattern recognitionCountermeasure

The invention discloses a face recognition attack defense method based on Rosenbrock-PSO. The method comprises the following steps: (1) collecting and preprocessing face image data, and dividing the face image data into a pre-training data set and a disturbance data set; (2) manufacturing a pure-color glasses frame template for limiting a disturbance area on the face image in the disturbance dataset; (3) training a face classifier of the face recognition model by using the pre-training data set; (4) constructing a Rosenbrock-PSO face attack model; (5) inputting a face image with a pure-colorglasses frame into the Rosenbrock-PSO face attack model for evolutionary optimization, to obtain a face image when RGB values on a glasses frame are optimal solutions, and the face image is used as anadversarial sample; and (6) adding the confrontation sample into the pre-training data set to retrain the face classifier, so that the face recognition model has the capability of defending against the attack of the confrontation sample. By utilizing the method and the device, the face recognition model which can defend countermeasure samples and has relatively high generalization ability can beobtained.

Owner:ZHEJIANG UNIV OF TECH

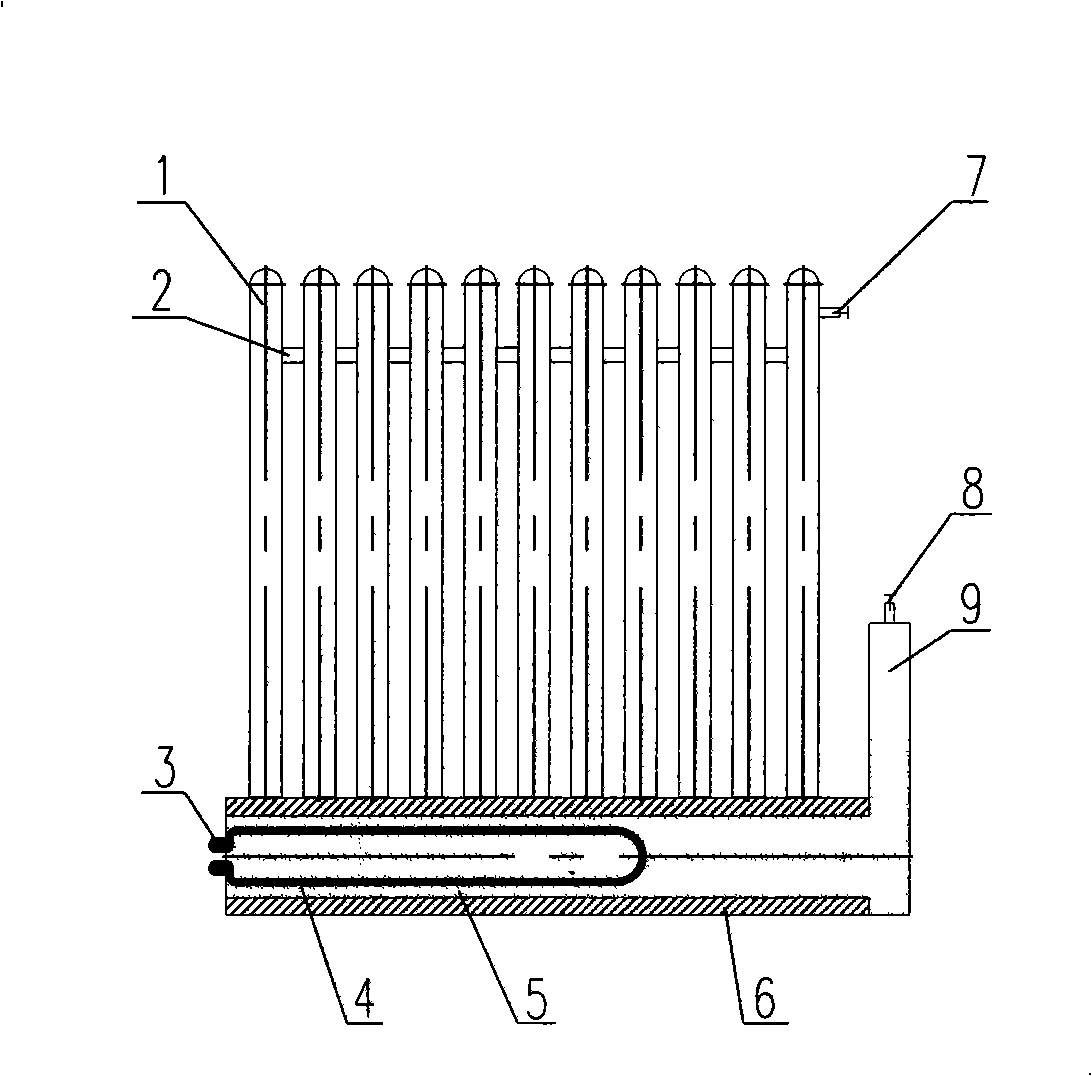

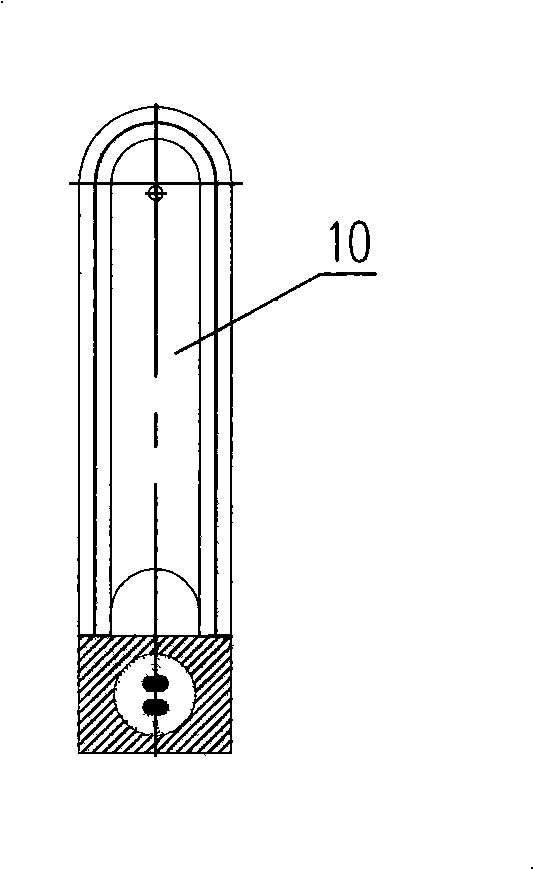

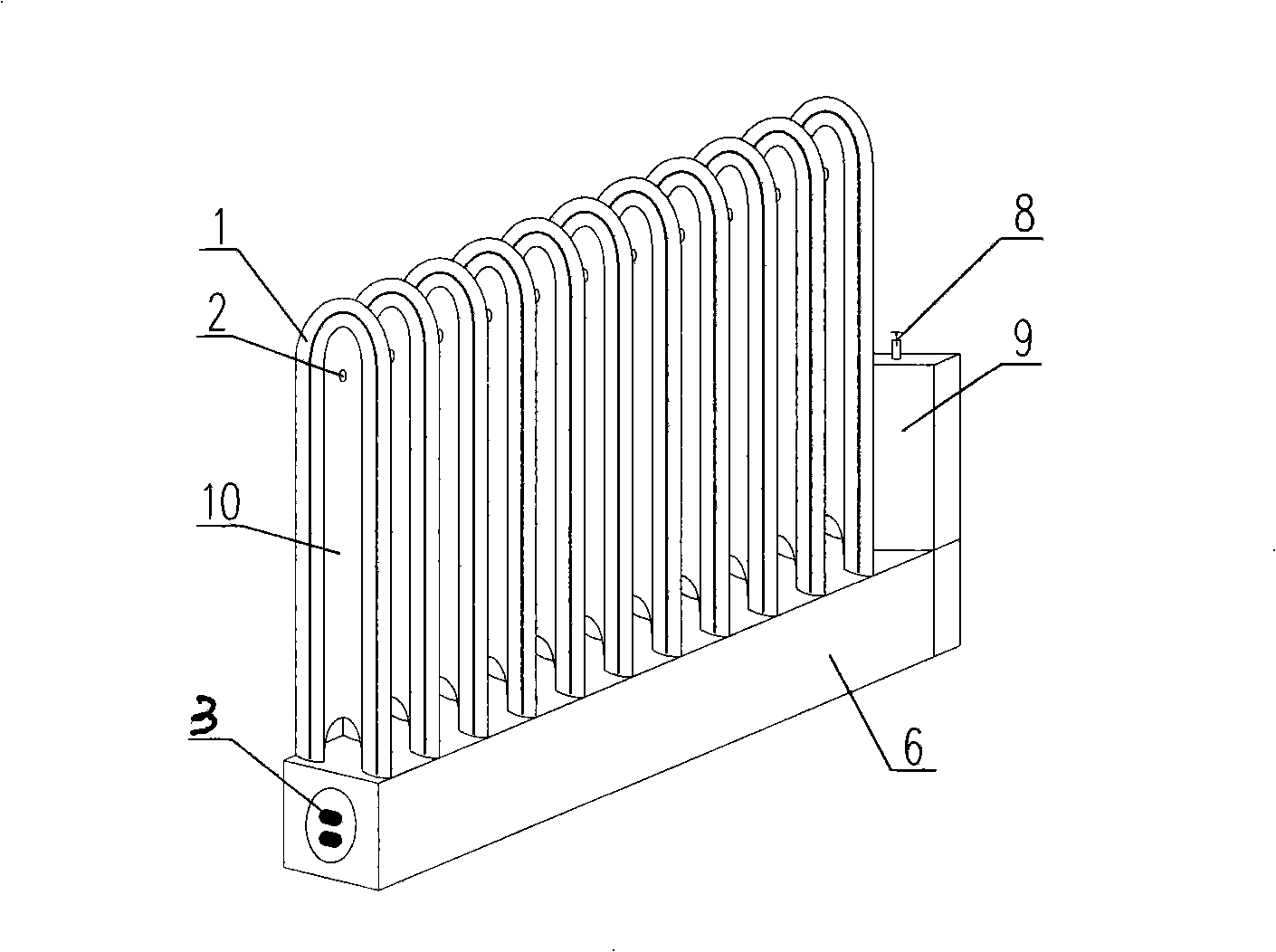

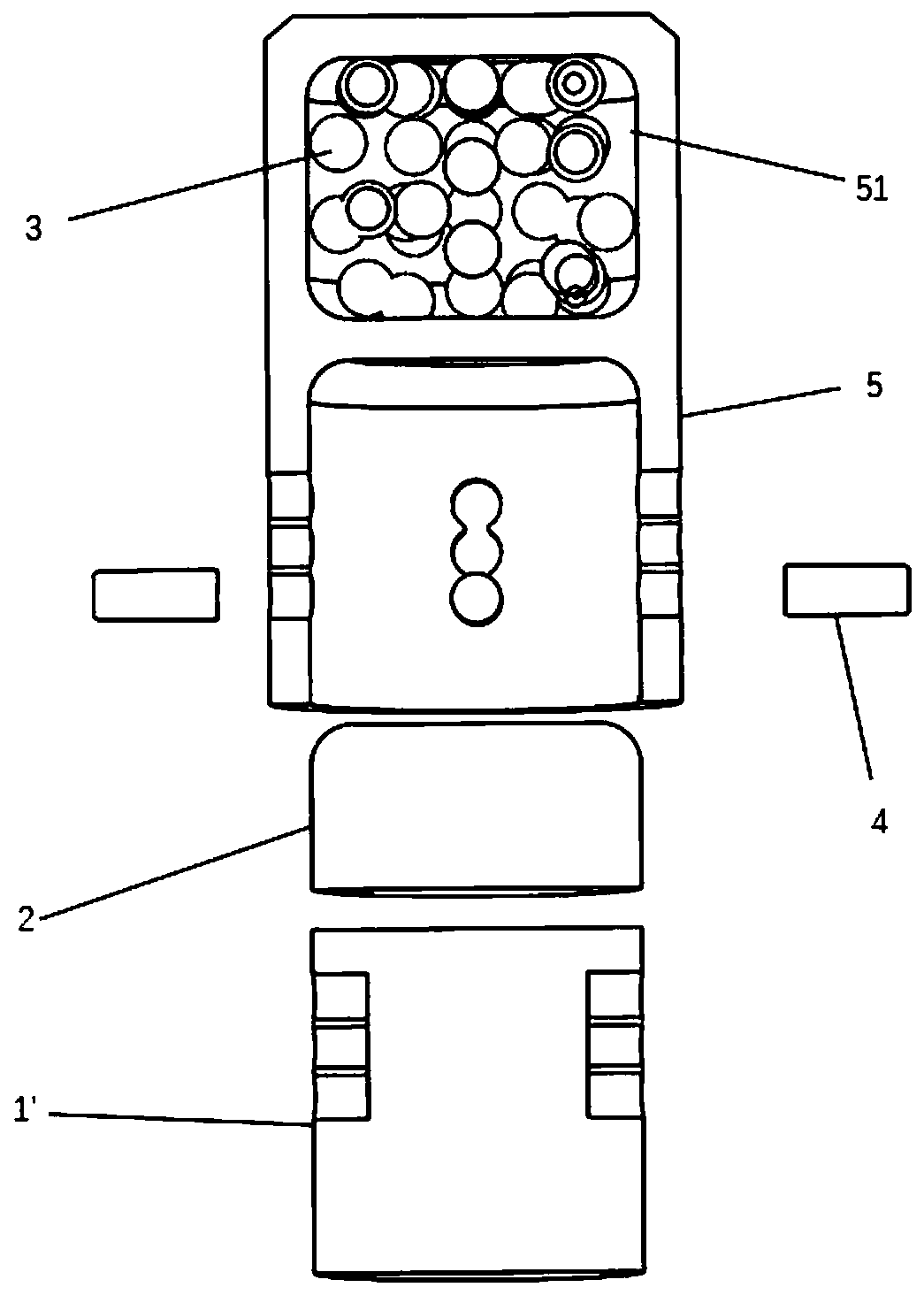

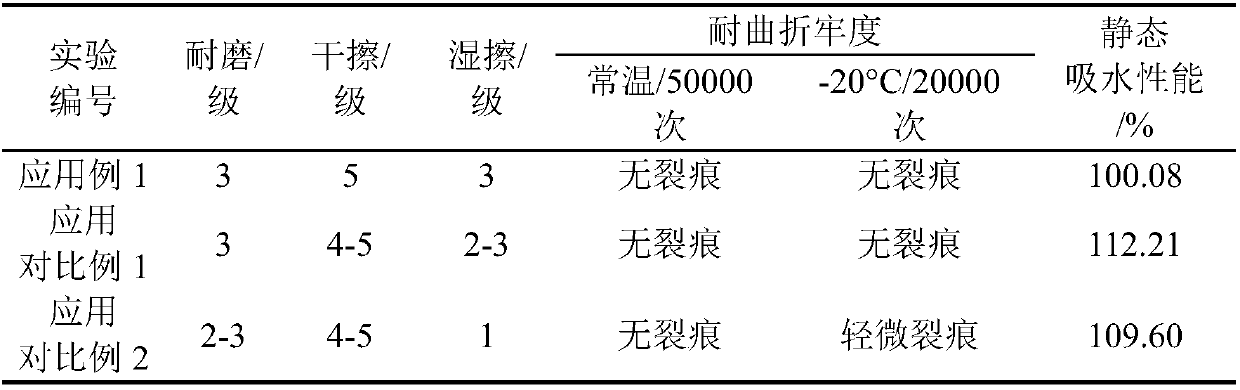

Heat conducting oil vacuum superconductor electric heater

InactiveCN101334187ANovel structural designImprove stability and securityElectric heating systemAir heatersElectric heatingEngineering

The invention discloses a heat conduction oil vacuum superconducting electric heater, which comprises inverse U-shaped vacuum heat conducting pipes and a heat conducting oil chamber. A superconducting liquid chamber is arranged outside the heat conducting oil chamber and presents an interlayer structure; the inverse U-shaped vacuum heat conducting pipes are arranged on the superconducting liquid chamber and are communicated with the superconducting liquid chamber; a superconducting liquid injection and vacuum pumping hole switch is arranged at the upper end of an inverse U-shaped vacuum heat conducting pipe at the end part, an electric heating pipe is arranged in the heat conducting oil chamber, a heat conducting oil expansion chamber communicated with the heat conducting oil chamber is arranged at one end of the heat conducting oil chamber, and a heat conducting oil injection and vacuum pumping switch is arranged on the heat conducting oil expansion chamber. The heat conduction oil vacuum superconducting electric heater solves the technical problems that the power consumption is large and the operation service life is short in the prior art through the combination and complementation of the heating of the electric heating pipe, the temperature rising of the heat conducting oil and the quick transmission of the superconducting liquid, therefore the heat conduction oil vacuum superconducting electric heater is an ideal heat conducting oil vacuum superconducting electric heater.

Owner:李少白

Method for low-temperature pretreatment of corn straw to improve gas production performance of anaerobic digestion by combination of sodium hydroxide and ammonia water

ActiveCN104593429AReduce preprocessing timeSupplement nitrogen nutritionFermentationNutrientAerobic digestion

The invention discloses a method for low-temperature pretreatment of a corn straw to improve gas production performance of anaerobic digestion by combination of sodium hydroxide and ammonia water, and belongs to the technical field of efficient resource utilization of the corn straw. The method comprises the following steps: carrying out pretreatment the corn straw at -20 to 20 DEG C by employing sodium hydroxide and ammonia as pretreatment agents, and carrying out sealed storage for 3 days, wherein the pretreatment agents are sodium hydroxide and ammonia water; adding water, so that the total mass of the added water, the water in the ammonia water and the water contained in the corn straw is six times of dry weight of the corn straw; fully stirring, and sealing by a sealing film; carrying out sealed storage in a refrigerator at -20 DEG C for 3 days, and then carrying out anaerobic fermentation, wherein activated sludge is needed in the anaerobic fermentation process; adding activated sludge, adding running water to reach 80% of total volume of the reaction device; filling nitrogen, and sealing by virtue of a rubber stopper; and fixing the reactor in a table concentrator, keeping the constant temperature of the table concentrator at 35+ / -2 DEG C and shaking. The method is mild in operation condition, and low in demands on compressive strength and corrosion resistance of the reactor; and the added ammonia water can be used as a nutrient of microorganisms, and is friendly to environment and low in secondary pollution.

Owner:BEIJING UNIV OF CHEM TECH

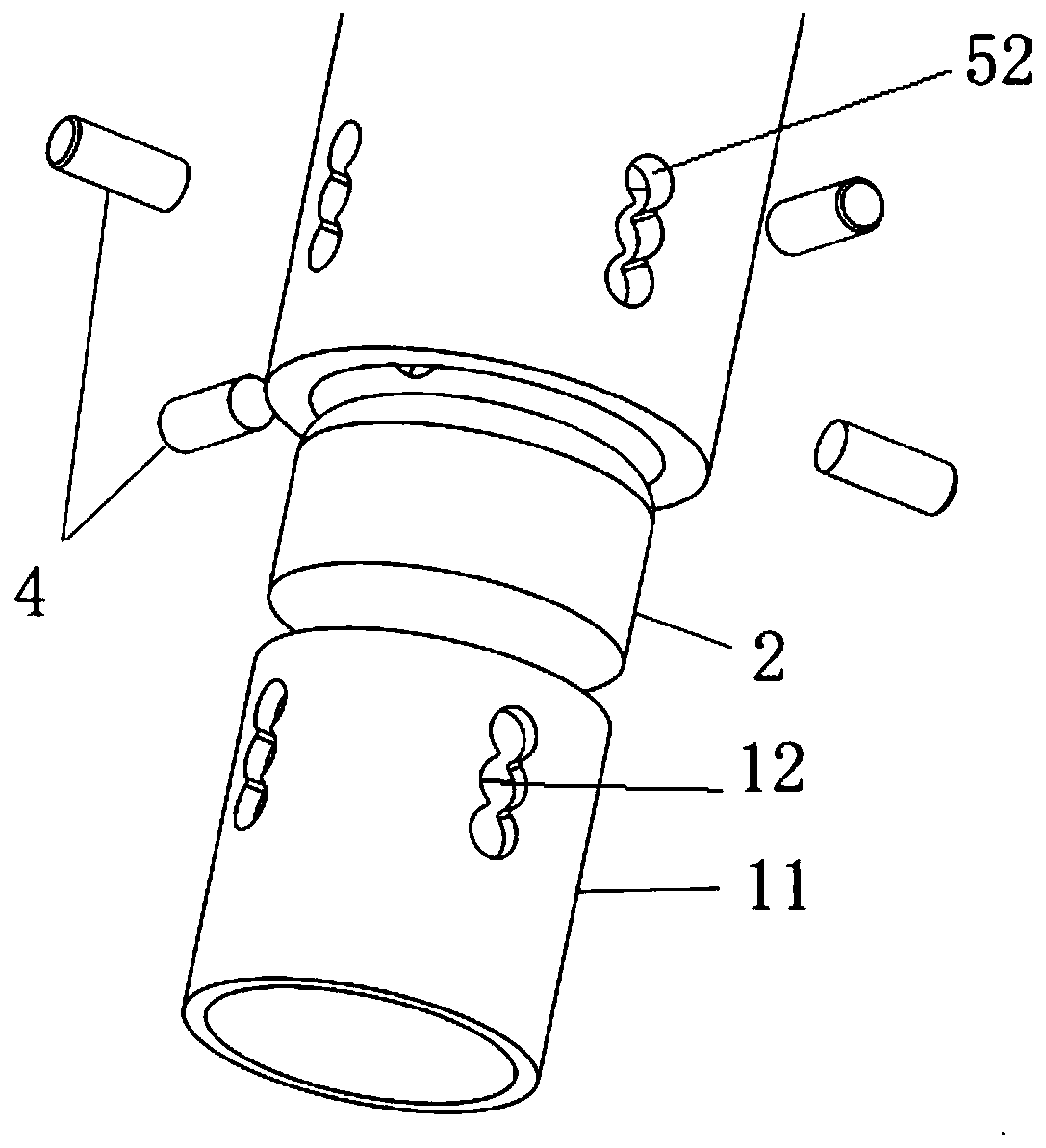

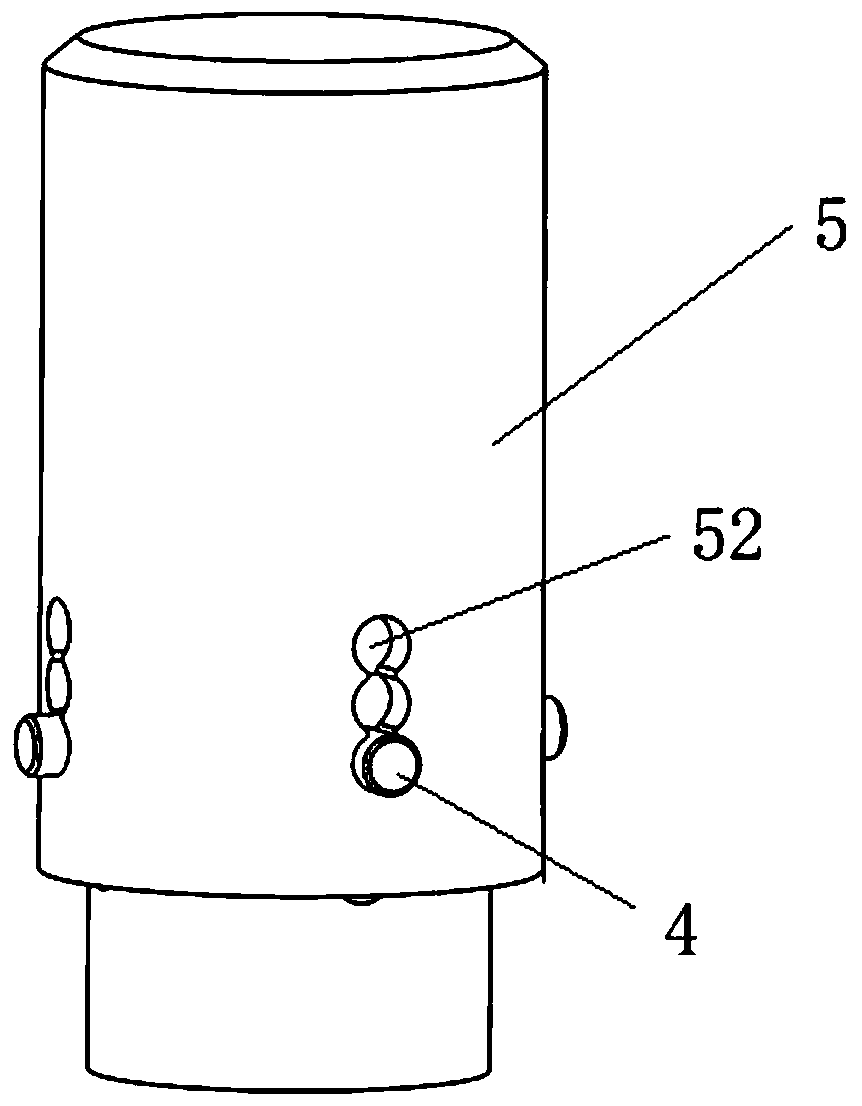

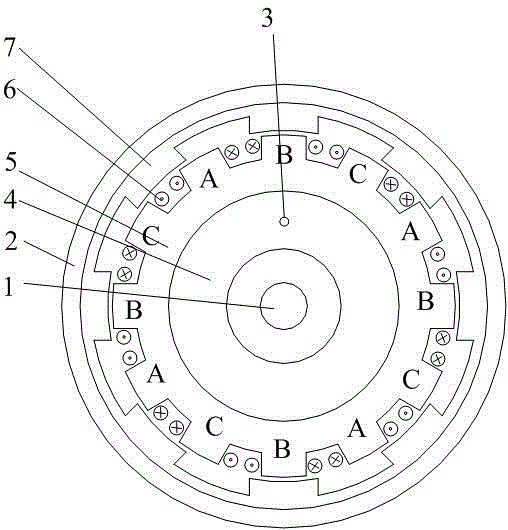

Multi-damping-layer local area resonon unit and application method thereof

PendingCN110230657AGood vibration and noise reductionEffective complementarySpringsSprings/dampers functional characteristicsMedium frequencyEngineering

The invention relates to a multi-damping-layer local area resonon unit. An inner spacing ring is arranged in a rigid outer shell for dividing an inner cavity of the rigid outer shell into upper and lower layers; a third powder damping layer is arranged in the upper-layer space, and is provided with powder particle bodies; the powder particle bodies are 65-75% of the total volume of the upper-layerspace; the lower-layer space is provided with a second viscous-elastic material damping layer and a first vibration layer in sequence from top to bottom; and the bottom of the first vibration layer is projected on the bottom edge of the rigid outer shell. Through structures of damping layers with three different materials, the prominent effects of the three damping layers on a medium-frequency area and a high-frequency area are complementary, so that the excellent damping and noise reducing effects are achieved; and multiple multi-damping-layer local area resonon units form lattices in use touniformly distribute on the outer surface of the shell, so that the effective vibration reducing frequency domain is greatly widened, and the obvious weakening effect on 200-4000 Hz vibration noise generated by a motor is achieved.

Owner:苏州英磁新能源科技有限公司

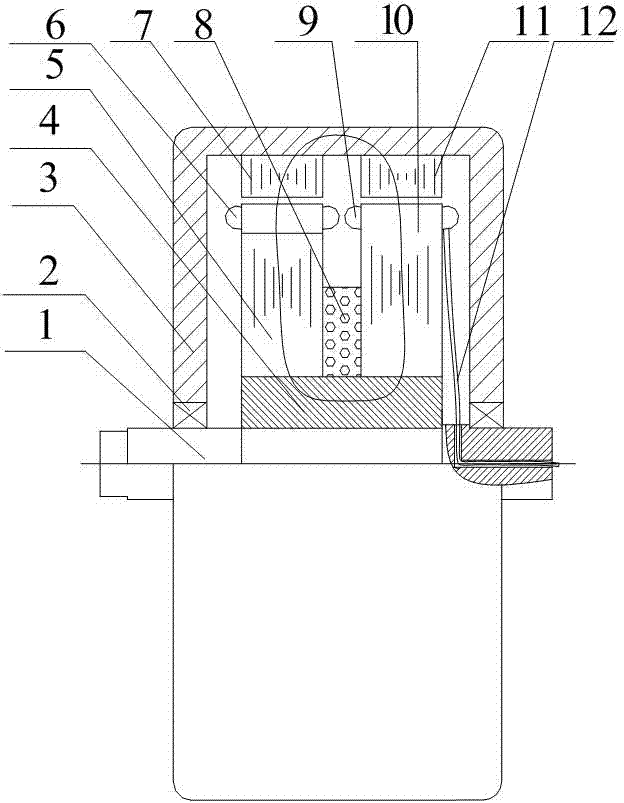

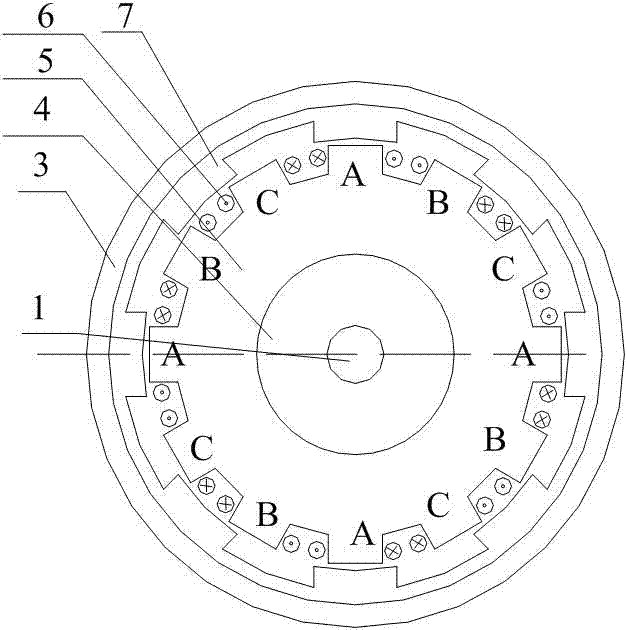

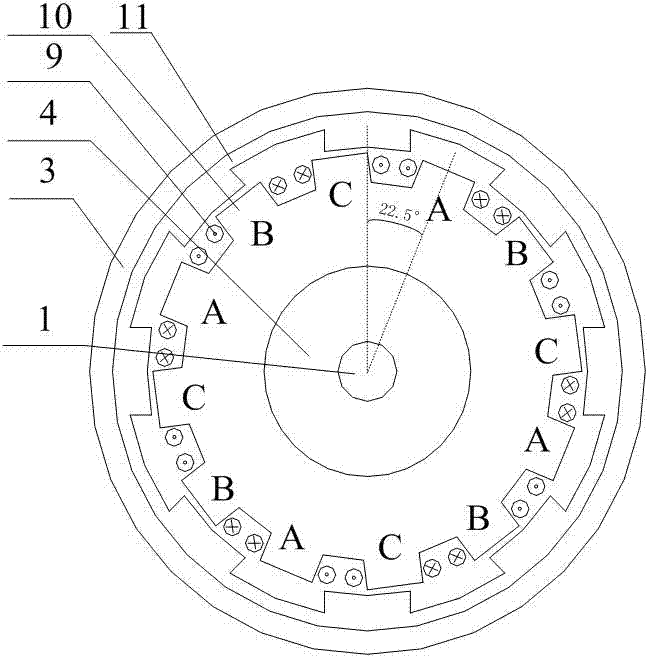

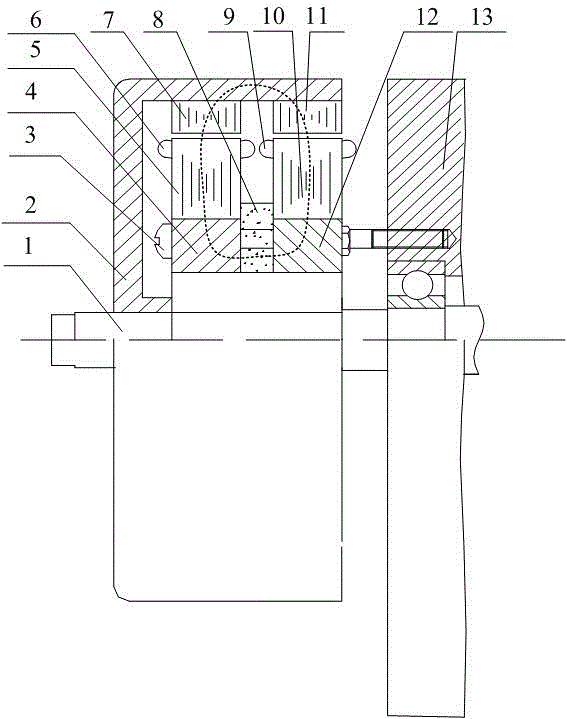

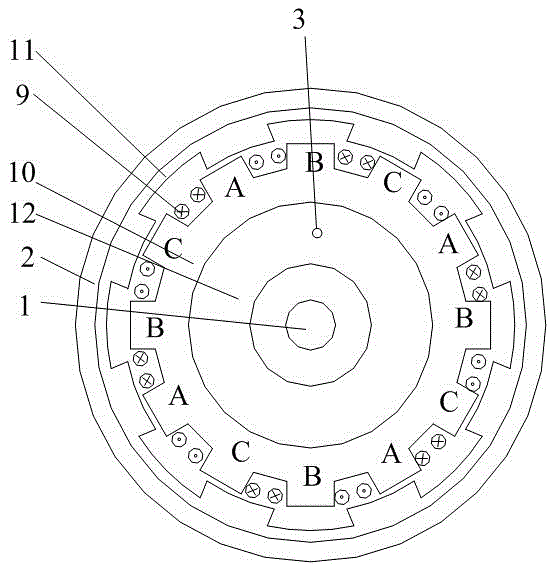

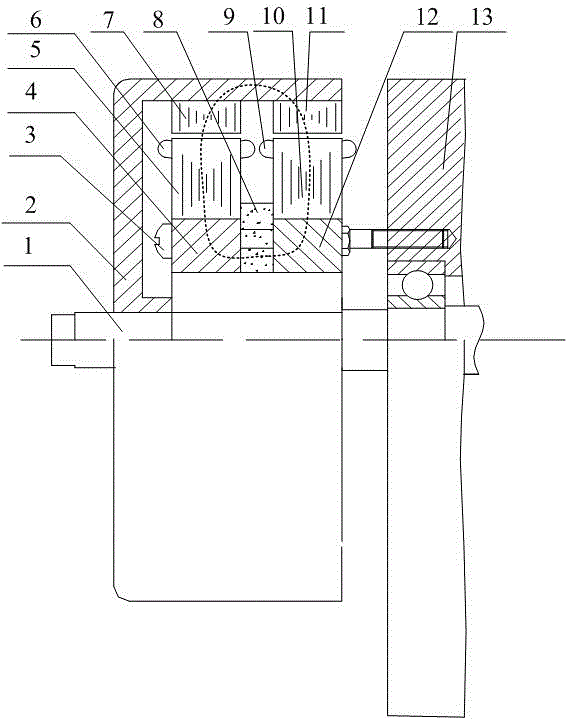

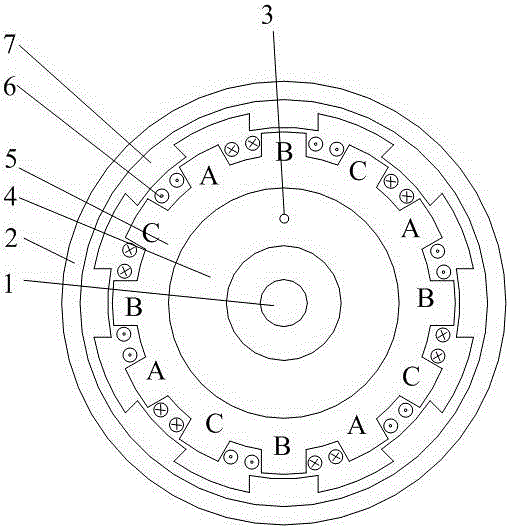

Motor generator with external rotor

ActiveCN104505961AReduce dosageCircumferential dimension shortMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductor Coil

The invention provides a motor generator with an external rotor. The motor generator with the external rotor comprises a shaft (1), a shell (3), a stator magnet yoke (4), an N-pole stator core (5), an S-pole stator core (10), an N-pole stator core (7), an S-pole stator core (11), an armature winding and an exciting winding (8), wherein the N-pole stator core (5) and the S-pole stator core (10) are arranged in the axial direction in a separated mode, the number of poles of the N-pole stator core (5) and the number of poles of the S-pole stator core (10) are 3n, and the exciting winding (8) is arranged between the two stator cores; the N-pole stator core (7) and the S-pole stator core (11) are arranged in the axial direction in a separated mode, the number of poles of the N-pole stator core (7) and the number of poles of the S-pole stator core (11) are equal and are 2n or 4n, and the difference angle between the N-pole stator core (7) and the S-pole stator core (11) in the circumferential direction is 360 / 4n degrees or 360 / 8n degrees. According to the motor generator, the exciting winding is small in circumferential size and low in consumption of enameled wires and copper loss; the path of magnetic circuits is short, most of the magnetic circuits pass through a silicon steel sheet, and therefore the iron loss is low; coils on an N-pole stator pole and coils on an S-pole stator pole can be effectively complemented with each other; the motor generator is provided with a flywheel type external rotor structure, and can work in a power-driven mode and work through electricity generation.

Owner:无锡恒和环保科技有限公司

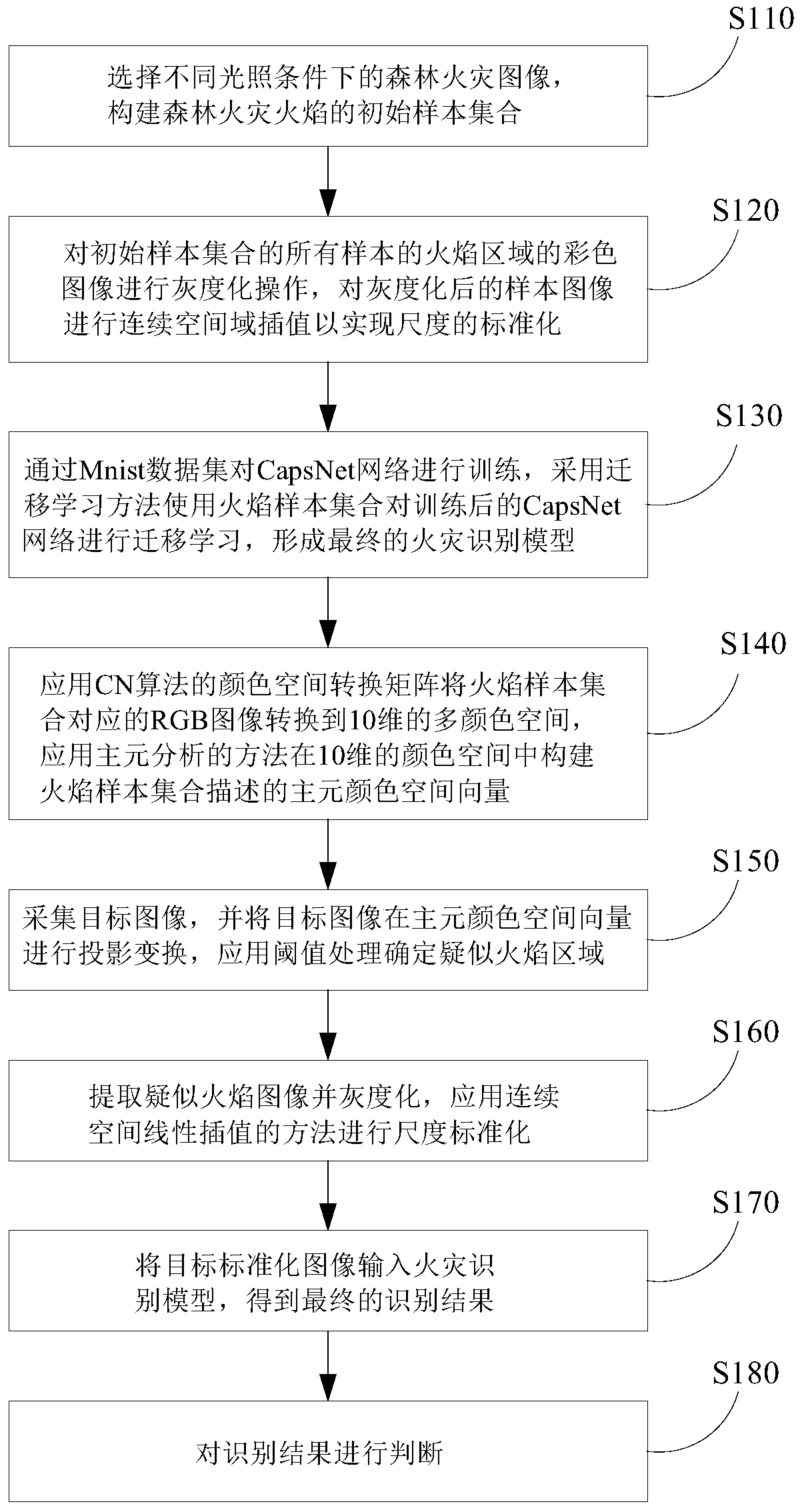

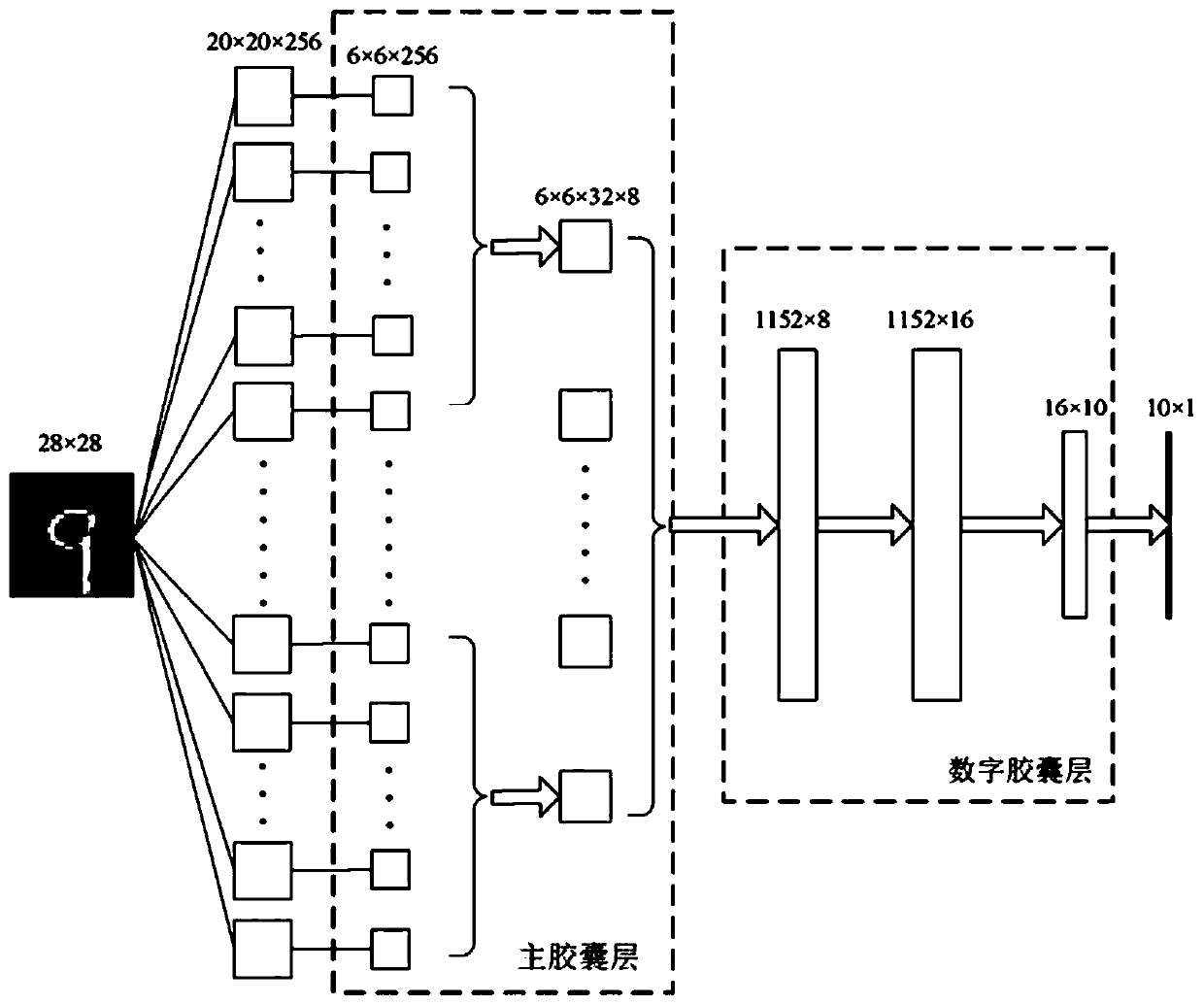

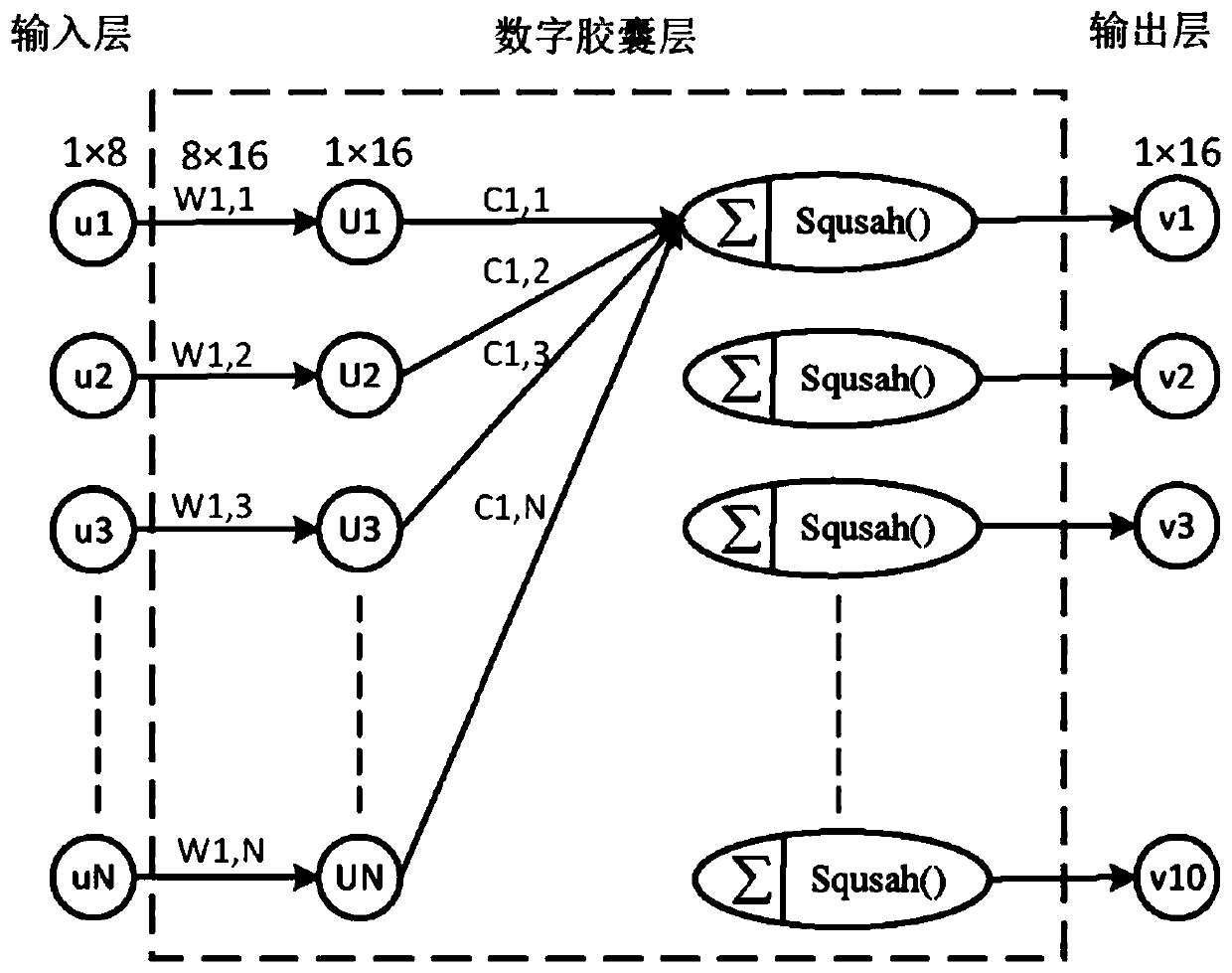

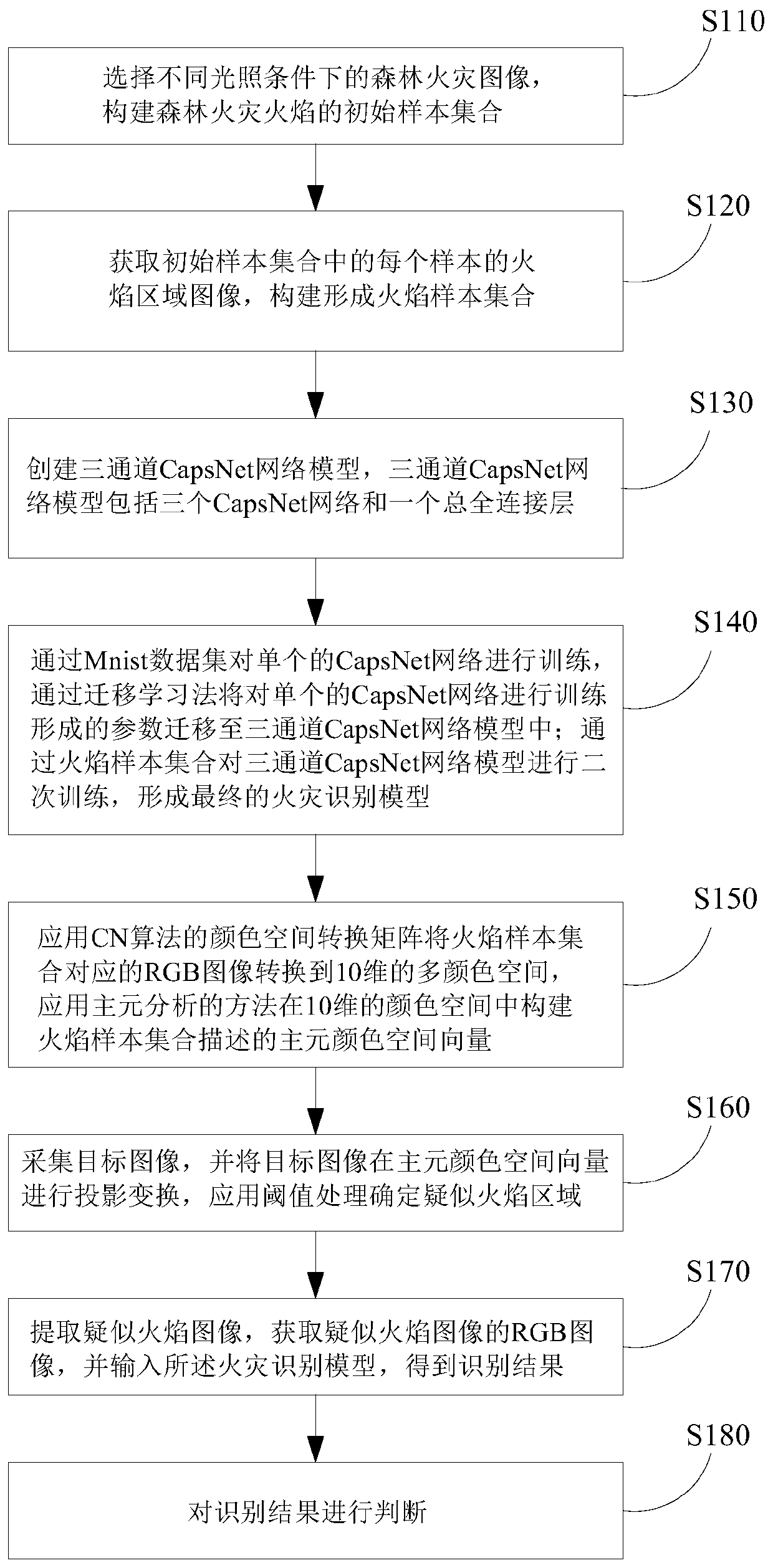

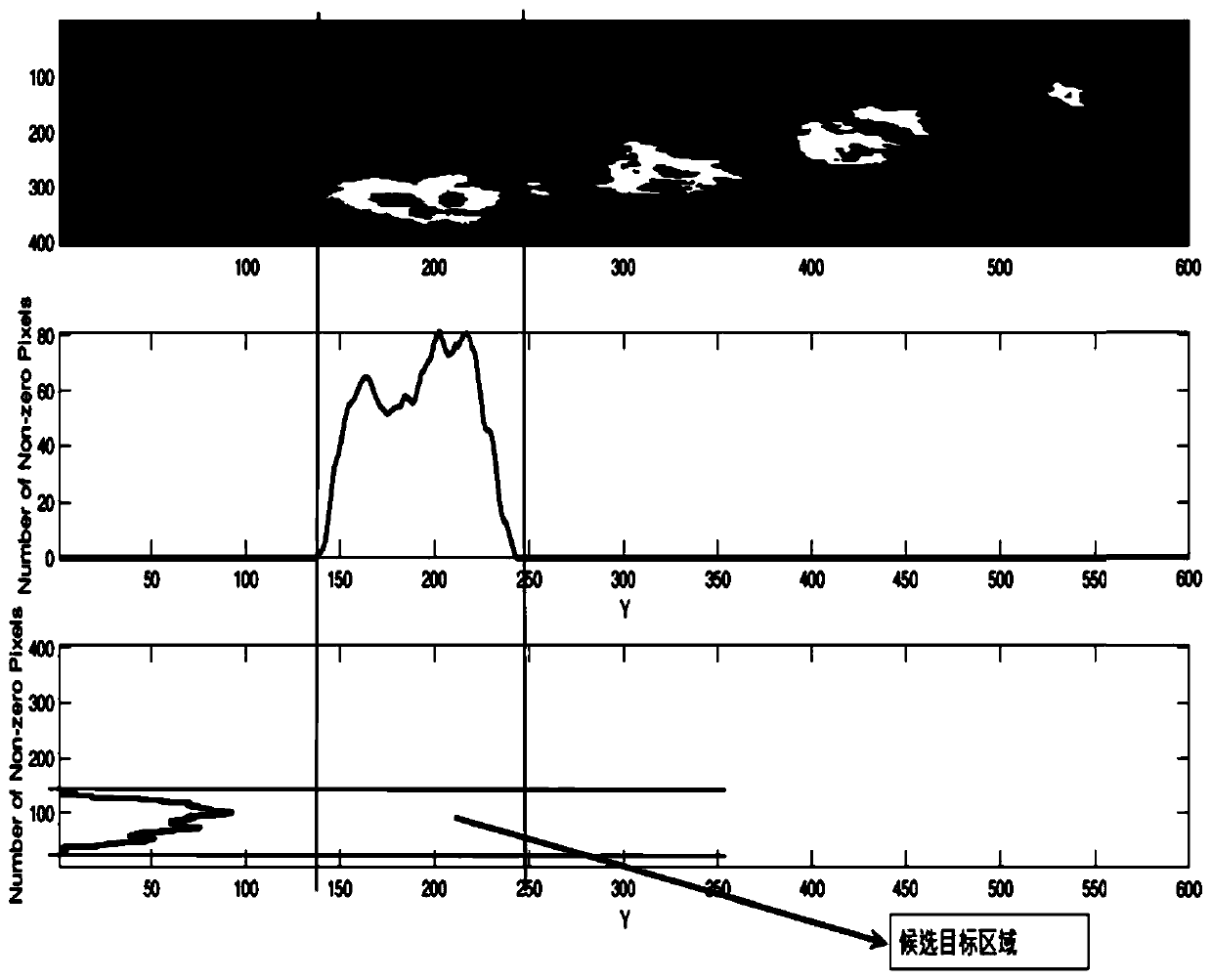

Forest fire identification method and device based on interpolated CN and capsule network

ActiveCN111291712AEffective complementaryImprove real-time performanceImage enhancementImage analysisAlgorithmEngineering

The invention discloses a forest fire identification method based on an interpolated CN and a capsule network. The forest fire identification method comprises the following steps: constructing an initial sample set of forest fire flames; performing graying operation on the initial sample set, and performing continuous spatial domain interpolation on the grayed sample image to realize scale standardization; training the CapsNet network through a transfer learning method to form a final fire identification model; constructing a principal component color space vector described by the flame sampleset by applying a CN algorithm; collecting a target image, and determining a suspected flame area; extracting a suspected flame image and graying, and performing scale standardization by applying a continuous spatial linear interpolation method; and inputting the target standardized image into a fire identification model to obtain a final identification result. The invention further discloses a forest fire identification device based on the interpolated CN and the capsule network. According to the invention, the real-time performance and effectiveness of fire detection are improved.

Owner:HENAN POLYTECHNIC UNIV

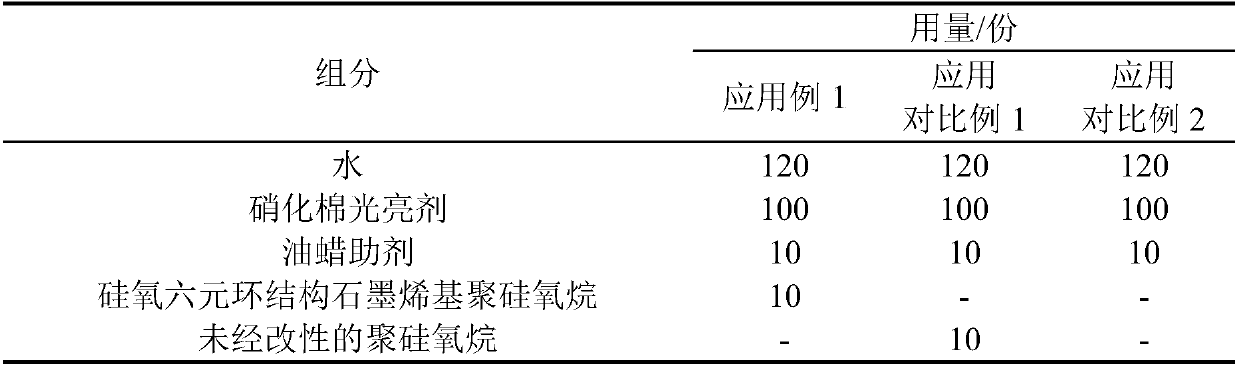

Preparation method of silicon oxide hexatomic ring structural graphene-based polyorganosiloxane

The invention relates to the technical field of graphene-based polyorganosiloxane materials, and provides a preparation method of silicon oxide hexatomic ring structural graphene-based polyorganosiloxane. Graphene oxide is adopted as a raw material, the graphene oxide is modified by the silane coupling agent and then has silane coupling agent modified polyorganosiloxane reaction by using a sol-gelmethod to prepare the silicon oxide hexatomic ring structural graphene-based polyorganosiloxane, so that the dispersion stability of the graphene oxide in the polyorgaonsiloxane can be effectively improved, the advantages of the polyorganosiloxane and graphene are complementary to each other, and a water soluble graphene modified polyorgaonsiloxane material with excellent performance such as electrostaticshielding, high physical performance, high mechanical strength, yellowing resistance and the like.

Owner:XINGYE LEATHER TECH CO LTD

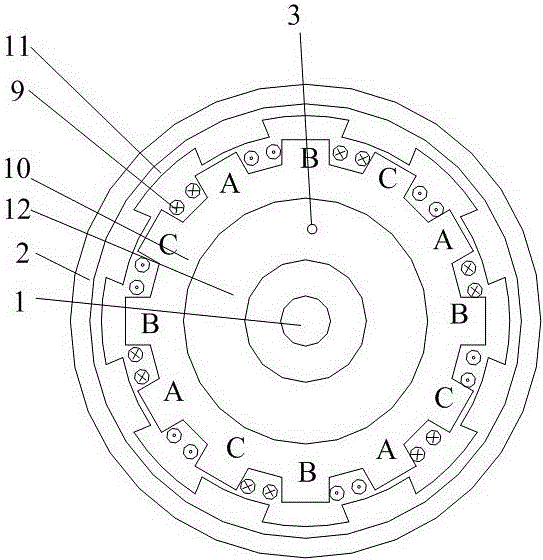

Flywheel type permanent magnet starter generator

ActiveCN104578655ASimple preparation processLittle effect of demagnetizationSynchronous machines with stationary armatures and rotating magnetsStarter generatorFlywheel

The invention provides a flywheel type permanent magnet starter generator which comprises a shaft (1), a flywheel (2), an N-pole magnetic yoke (4), stator cores, an armature winding, an N-pole rotor core (7), a permanent magnet (8), an S-pole rotor core (11) and an S-pole magnetic yoke (12). The stator cores are formed by axially arranging an N-pole stator core and an S-pole stator core at intervals, the number of poles of the N-pole stator core and the number of poles of the S-pole stator core are 3n, and an excitation element is arranged between the two stator cores. Rotor cores are formed by axially arranging the N-pole rotor core and the S-pole rotor core at intervals, the number of poles of the N-pole rotor core and the number of poles of the S-pole rotor core are 2n or 4n, and the N-pole rotor core and the S-pole rotor core differ by 360 degrees / 4n or 360 degrees / 8n in the circumferential direction. The generator is small in permanent magnet demagnetization effect, and short in magnetic path, most of a magnetic path passes through a silicon steel sheet, and therefore iron losses are small. A coil on the N-pole stator pole and a coil on the S-pole stator pole can effectively compensate each other. The flywheel type permanent magnet starter generator is provided with a flywheel type outer rotor structure and can be in starting and power generation running.

Owner:SHANDONG UNIV OF TECH

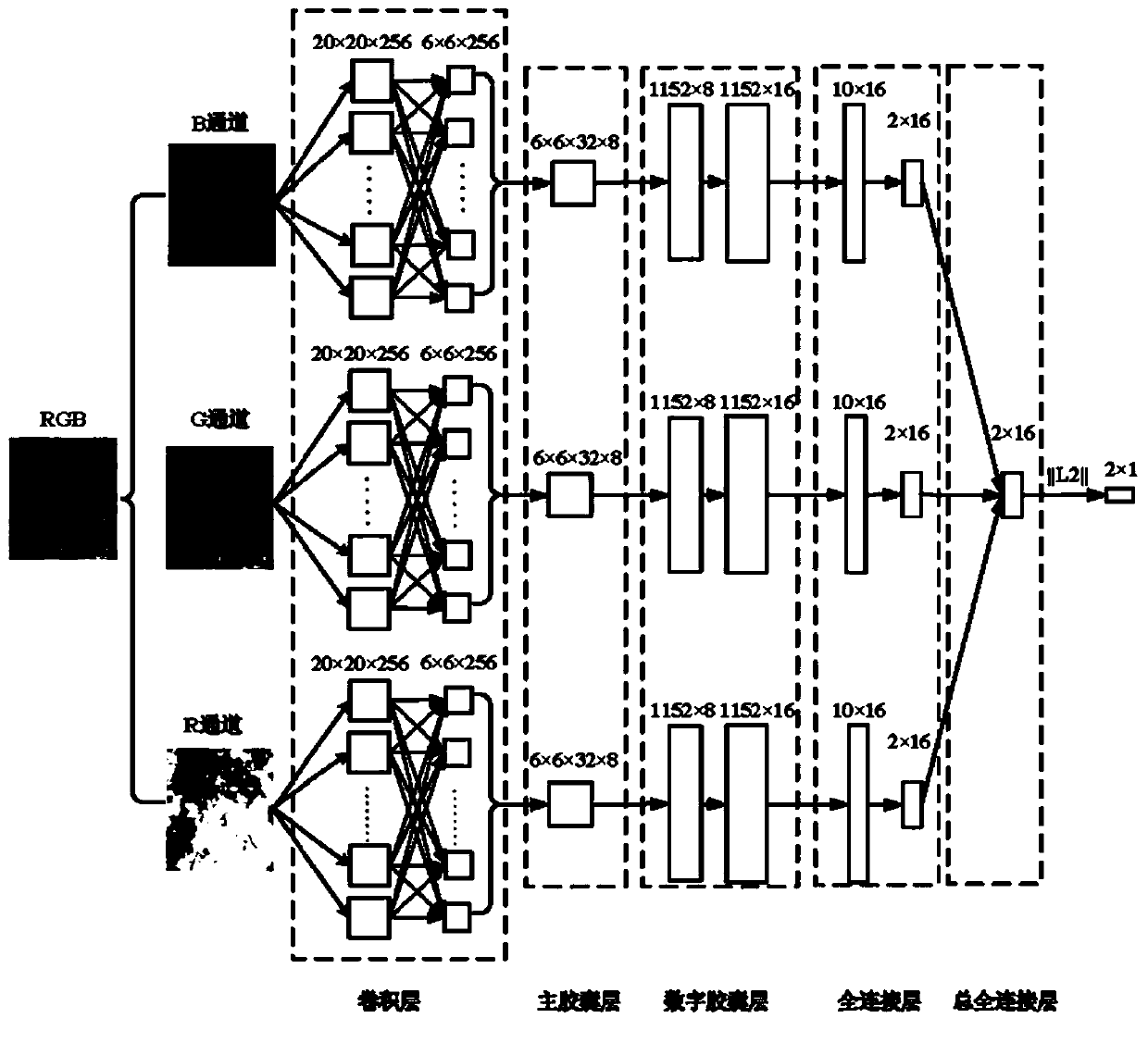

Forest fire identification method and device based on CN and three-channel capsule network

ActiveCN111310690AEffective complementaryImprove real-time performanceClimate change adaptationScene recognitionData setSimulation

The invention discloses a forest fire identification method and device based on a CN and a three-channel capsule network. The identification method comprises the following steps: constructing an initial sample set of forest fire flames; acquiring a flame region image of each sample in the initial sample set, and constructing to form a flame sample set; creating a three-channel CapsNet network model according to the three-channel CapsNet network model; the method comprises the following steps: training a single CapsNet network through a Mnist data set; migrating parameters formed by training asingle CapsNet network into the three-channel CapsNet network model, wherein the parameters of a total full connection layer in the three-channel CapsNet network model are realized through random initialization; performing secondary training on the three-channel CapsNet network model through the flame sample set to form a final fire identification model; and constructing a principal component color space vector described by the flame sample set by applying a CN algorithm. According to the invention, the real-time performance and effectiveness of fire detection are improved.

Owner:HENAN POLYTECHNIC UNIV

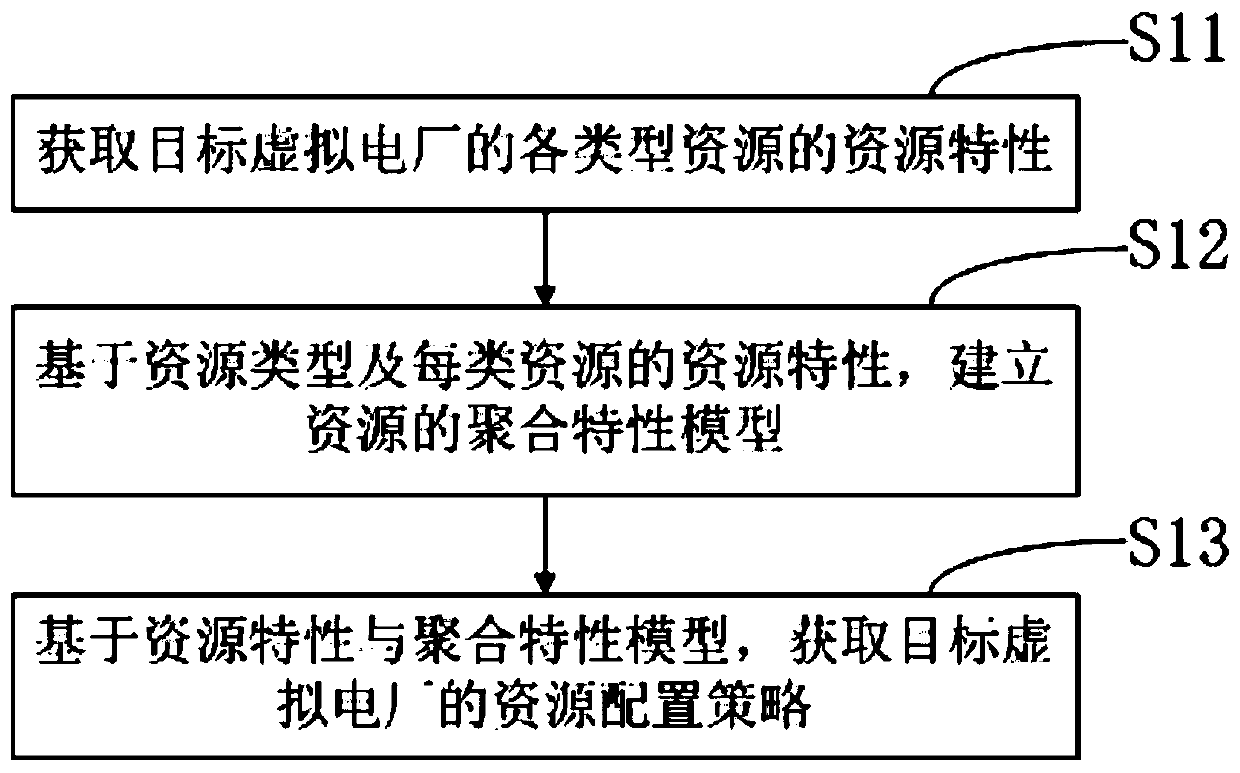

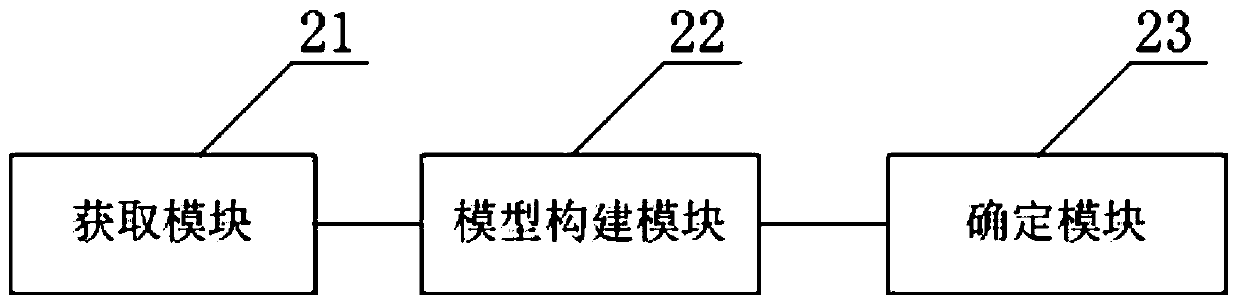

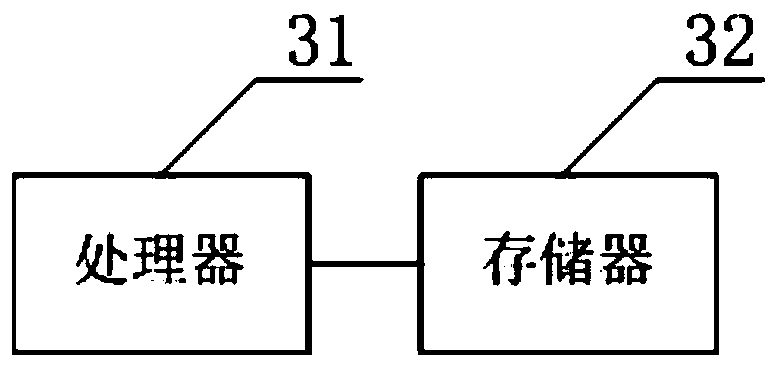

Virtual power plant resource optimal configuration method, device and equipment

PendingCN111382939ASupport multi-time scale regulation goalsEffective complementaryCharacter and pattern recognitionResourcesControl engineeringVirtual power plant

The invention relates to a virtual power plant resource optimal configuration method, a device and equipment. The method comprises the steps of obtaining resource characteristics of various types of resources of a target virtual power plant; based on the resource types and the resource characteristics of each type of resources, establishing an aggregation characteristic model of the resources; andobtaining a resource configuration strategy of the target virtual power plant based on the resource characteristics and the aggregation characteristic model. Based on complementary advantages of different energy forms, various electric heating coupling devices are brought into a virtual power plant resource regulation and control range, an aggregation characteristic model of multi-energy multi-body devices is established, effective complementation and full utilization of multi-energy resources are achieved, and a virtual power plant multi-time-scale regulation and control target is supported.

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY +1

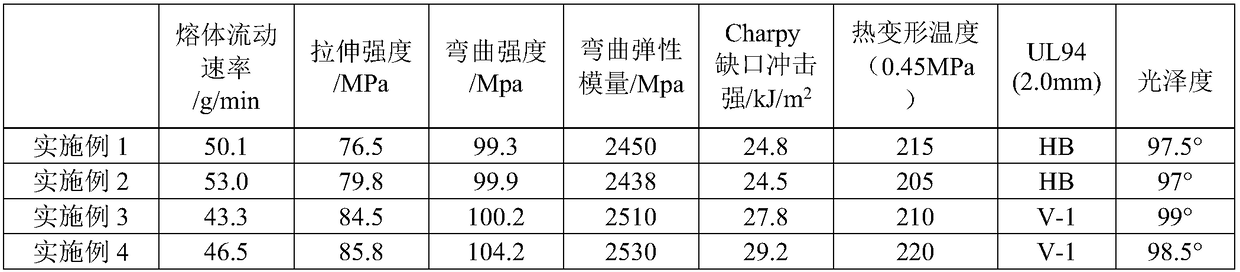

PA66/PPO composite material and preparation method thereof

The invention discloses a PA66 / PPO composite material and a preparation method thereof. The PA66 / PPO composite material is composed of the following components in parts by weight: 15-25 parts of low-viscosity polyhexamethylene adipamide, 15-25 parts of high-viscosity polyhexamethylene adipamide, 20-35 parts of polyphenylene ether, 1-10 parts of a compatibilizer A, 1-10 parts of a compatibilizer B,1-10 parts of a toughening agent, 1-5 parts of a lubricant A, 0.1-2 parts of a lubricant B, 0.1-1 part of an antioxidant A, 0.1-1 part of an antioxidant B, 2-8 parts of a flame retardant, 0.1-1 partof a heat stabilizer, and 0.2-1 part of a dispersant, wherein the low-viscosity polyhexamethylene adipamide has viscosity of 1.05-1.1Pa*s, and the high-viscosity polyhexamethylene adipamide has viscosity of 2.55-2.85Pa*s. The PA66 / PPO composite material disclosed by the invention has the advantages of high strength, high impact, high heat resistance, difficult flammability, and excellent electrical insulating performance and flame retardance.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Breeding method capable of increasing penaeus vannamei yield

InactiveCN107836386AEasy to adjustPromote ecological balanceFlowers cultivationFood processingFisheryShrimp disease

The invention discloses a breeding method capable of increasing the penaeus vannamei yield. The method comprises the following steps of pond arrangement; shrimp fry putting, wherein penaeus vannamei fry with the size ranging from 0.6 cm to 1 cm is selected, 55,000-65,000 fry is put per mu, and after breeding is conducted for 17-19 days, fishes obtained after disinfection treatment are put for mixed breeding; feed management, wherein feed feeding is conducted 2-3 times each day; daily management; shrimp disease prevention, wherein a disinfection reagent and a probiotic preparation are splashedeach month. According to the breeding method capable of increasing the penaeus vannamei yield, the breeding resources are fully utilized, the morbidity of the penaeus vannamei is low, the weight is increased rapidly, the yield is high, the breeding risk is effectively lowered, and the breeding benefit of the penaeus vannamei is increased.

Owner:定远县和润水产养殖专业合作社

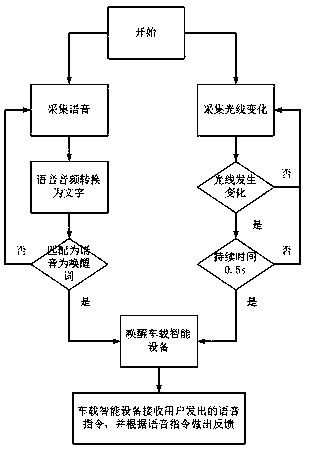

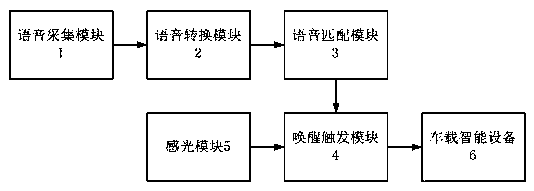

Awakening method and device for intelligent vehicle-mounted equipment

PendingCN109545215AImprove user experienceIncrease light sense wake-up technologySpeech recognitionComputer scienceSpeech sound

The invention provides an awakening method and device for intelligent vehicle-mounted equipment. The awakening method comprises the steps that voice and light ray change of the intelligent vehicle-mounted equipment in a preset range are collected at the same time; if the voice is collected, the collected voice frequency is converted into characters through a semantic parsing engine, the charactersare matched with preset awakening words, and when the characters are the awakening words through matching, the intelligent vehicle-mounted equipment is awakened; if light ray change of the intelligent vehicle-mounted equipment in the preset range is collected, the intelligent vehicle-mounted equipment is awakened. According to the awakening method, on the basis of voice awakening, the light sensation awakening technology is added, the awakening action of the device is simple, the awakening success rate is increased, and the use experience of a user is improved.

Owner:广州亿宏信息科技有限公司

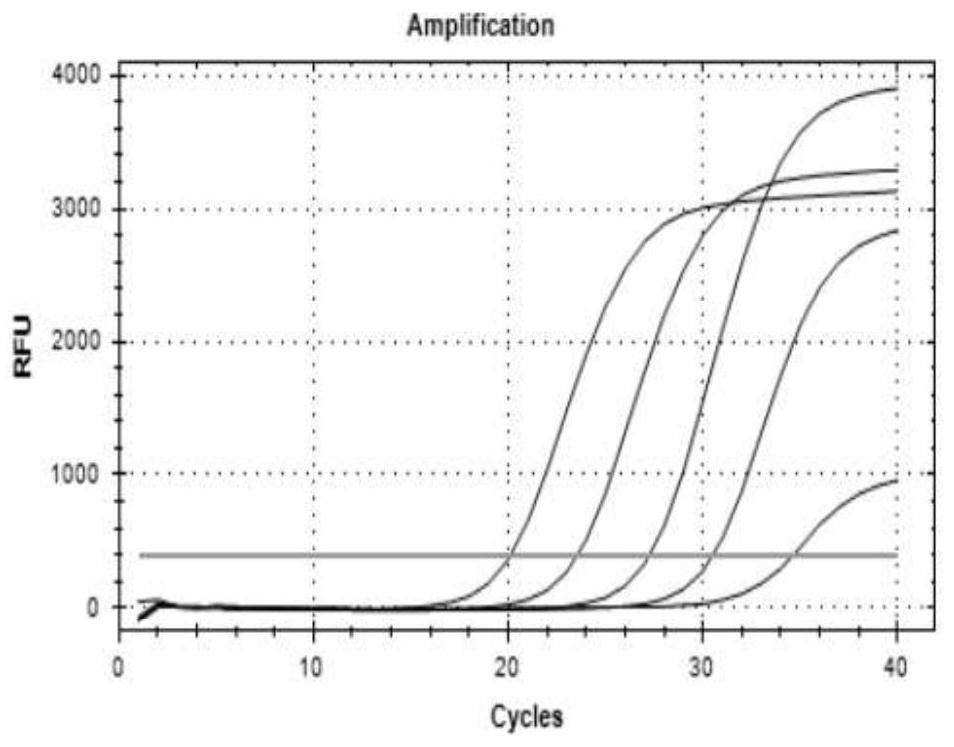

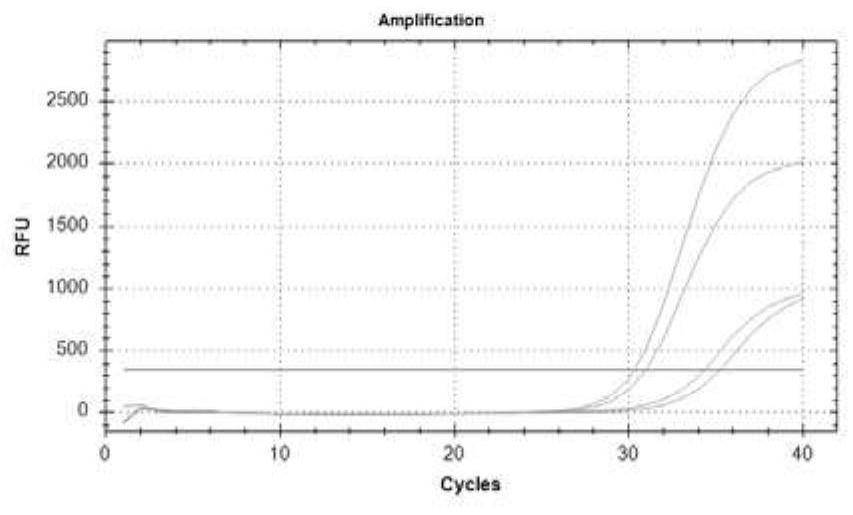

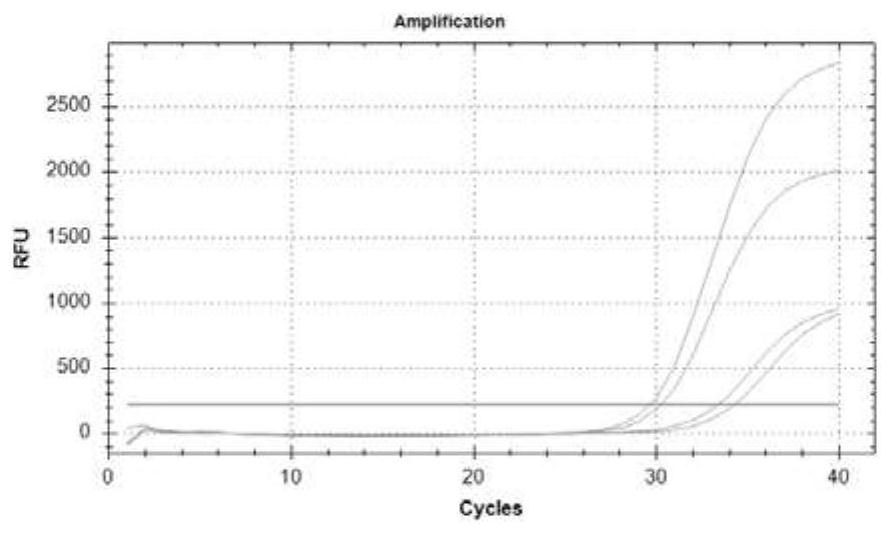

Nucleic acid combination and kit for colorectal cancer gene methylation detection

ActiveCN113981083AStrong specificitySame sensitivityMicrobiological testing/measurementDNA/RNA fragmentationNucleotideOncology

The invention provides a nucleic acid combination and a kit for colorectal cancer gene methylation detection, and relates to the technical field of gene detection. The nucleic acid combination comprises a first specific primer pair and a first specific probe which are used for detecting Septin9 gene methylation, a second specific primer pair and a second specific probe which are used for detecting SDC2 gene methylation, and a third specific primer pair and a third specific probe which are used for detecting NDRG4 gene methylation, wherein the base sequence of the first specific primer pair, the base sequence of the second specific primer pair, the base sequence of the third specific primer pair, the base sequence of the first specific probe, the base sequence of the second specific probe and the base sequence of the third specific probe are modified through locked nucleotides. According to the invention, methylation sites in the primer and the probe are subjected to locked nucleic acid modification, so that the detection specificity is greatly improved; and three genes are subjected to joint detection, so that the best detection effect is achieved.

Owner:JIANGSU COWIN BIOTECH CO LTD +2

Antibacterial and antiphlogistic beautification facial plaster of apocynum

InactiveCN1660306AAnti agingGood comprehensive beauty effectUnknown materialsDermatological disorderApocynumActive component

An antibacterial inflammation-relieving face-beautifying mask is composed of carrier (cloth) and the active component prepared from kendir extract, chitosan and aloe extract.

Owner:天津市天益华泰科技发展有限公司

A flywheel type permanent magnet starter generator

ActiveCN104578655BSimple preparation processLittle effect of demagnetizationSynchronous machines with stationary armatures and rotating magnetsStarter generatorPermanent magnet synchronous generator

The invention proposes a flywheel type permanent magnet starter generator, comprising a shaft (1), a flywheel (2), an N-pole yoke (4), a stator core, an armature winding, an N-pole rotor core (7), a permanent Magnet (8), S pole rotor core (11) and S pole yoke (12). The stator core is composed of an N-pole stator core with a pole number of 3n and an S-pole stator core arranged at intervals in the axial direction, and the excitation element is in the middle of the two stator cores; the rotor core is composed of an N-pole rotor core with a pole number of 2n or 4n and an S pole. The pole stator cores are arranged at intervals in the axial direction, and the difference between the N-pole rotor core and the S-pole rotor core in the circumferential direction is 360° / 4n or 360° / 8n. The demagnetization effect of the permanent magnet of the motor of the present invention is small; its magnetic circuit path is short, and most of the magnetic circuit passes through the silicon steel sheet, so the iron loss is small; the coil on the N pole stator pole and the coil on the S pole stator pole can effectively complement each other; It has a flywheel type outer rotor structure and can start and generate electricity.

Owner:SHANDONG UNIV OF TECH

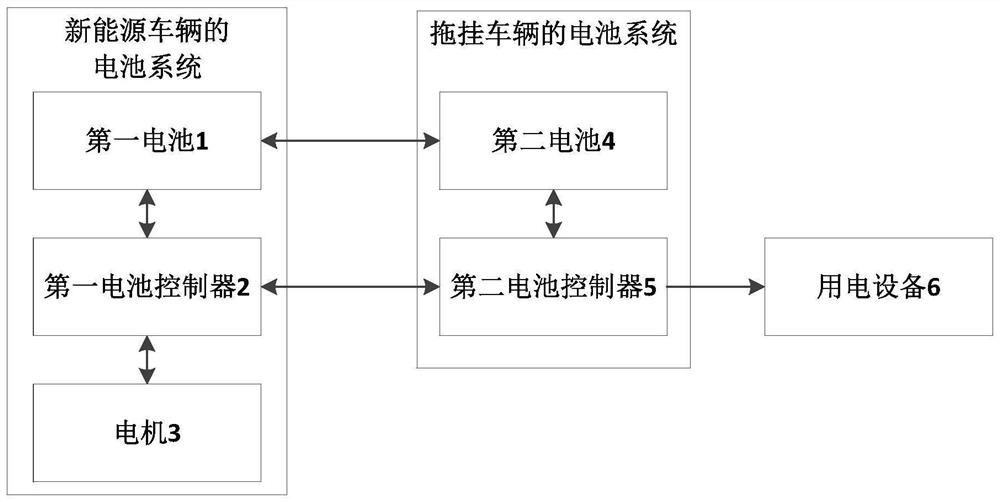

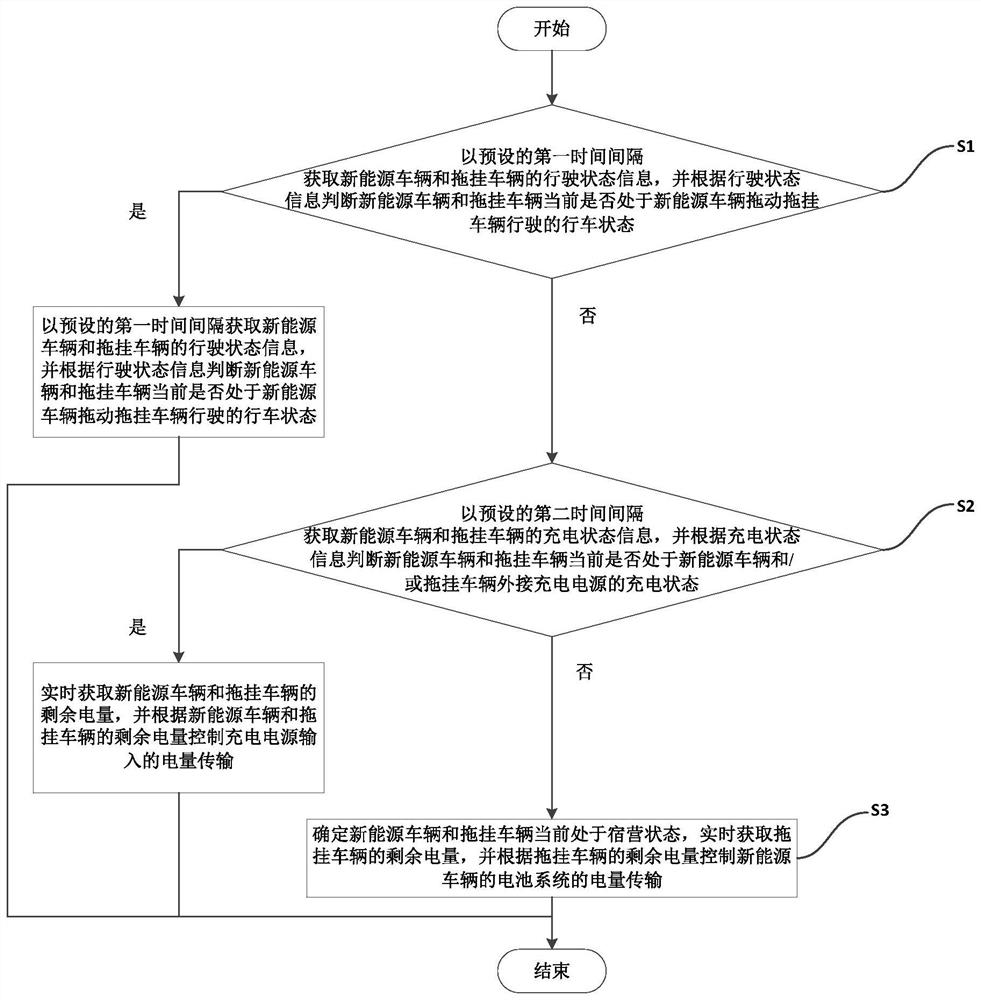

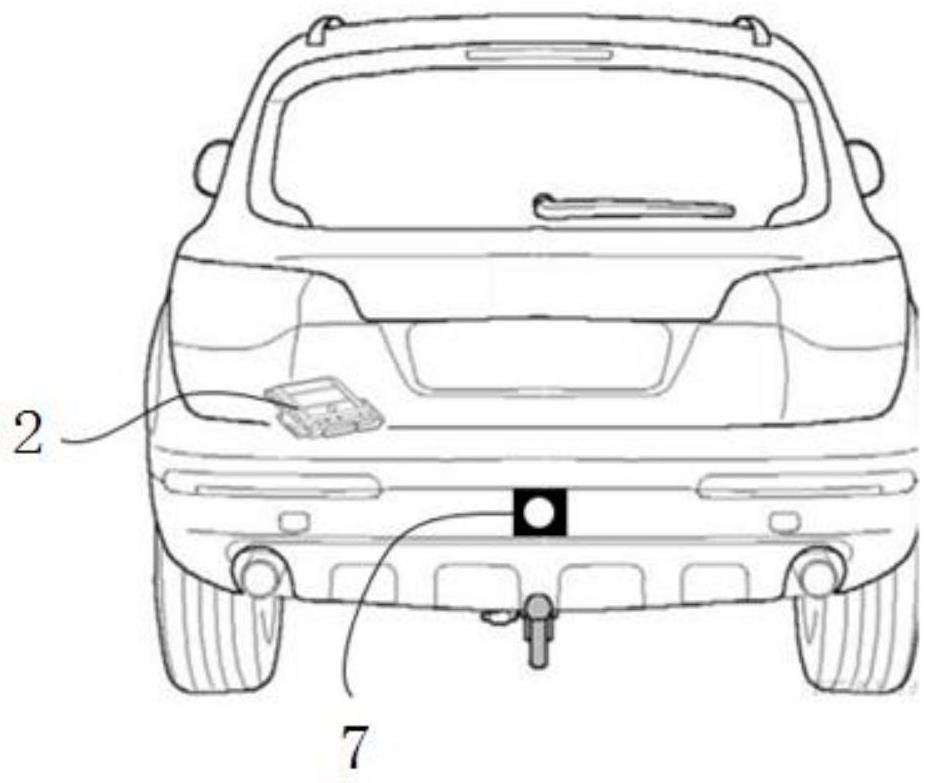

Charging and discharging control method for vehicle and trailer vehicle, vehicle control unit and vehicle

PendingCN114714977AImprove battery lifeImprove ease of useCircuit monitoring/indicationElectric powerElectrical batteryNew energy

The invention provides a charging and discharging control method for a new energy vehicle and a trailer, a vehicle control unit and a vehicle. A trailer is towed behind the new energy vehicle, and a battery system of the new energy vehicle is electrically connected with a battery system of the trailer. The charging and discharging control method comprises the steps that whether the new energy vehicle and the trailer are in a driving state or not is judged; if yes, when the remaining electric quantity of the new energy vehicle is smaller than a preset first electric quantity threshold value, a battery system of the trailer is controlled to transmit electric energy to a battery system of the new energy vehicle; if not, whether the new energy vehicle and the trailer are in a charging state or not is judged; if yes, electric quantity transmission input by the charging power source is controlled according to the remaining electric quantity of the new energy vehicle and the trailer; if not, electric quantity transmission of a battery system of the new energy vehicle is controlled according to the remaining electric quantity of the trailer. According to the scheme, the endurance mileage of the vehicle can be prolonged, and the use convenience of the electric equipment for towing the vehicle is improved.

Owner:摩登汽车有限公司

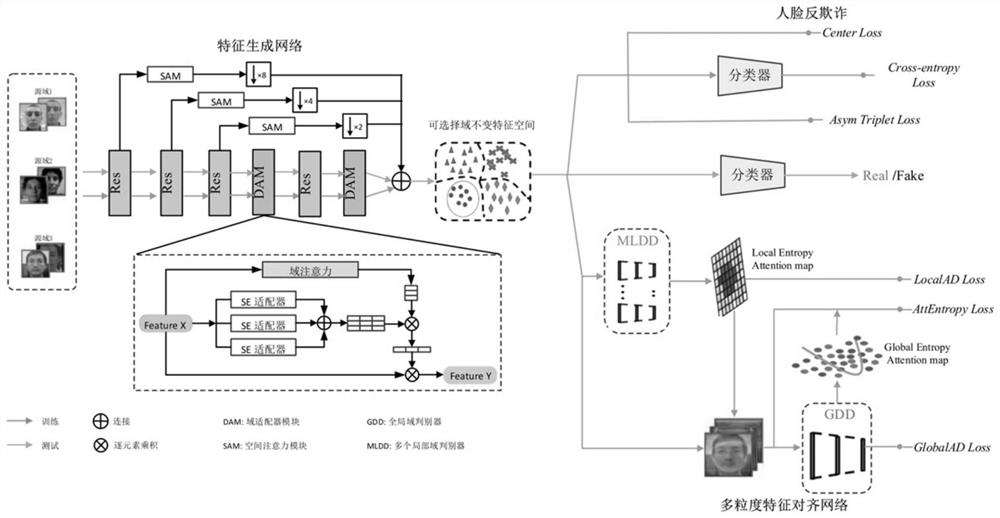

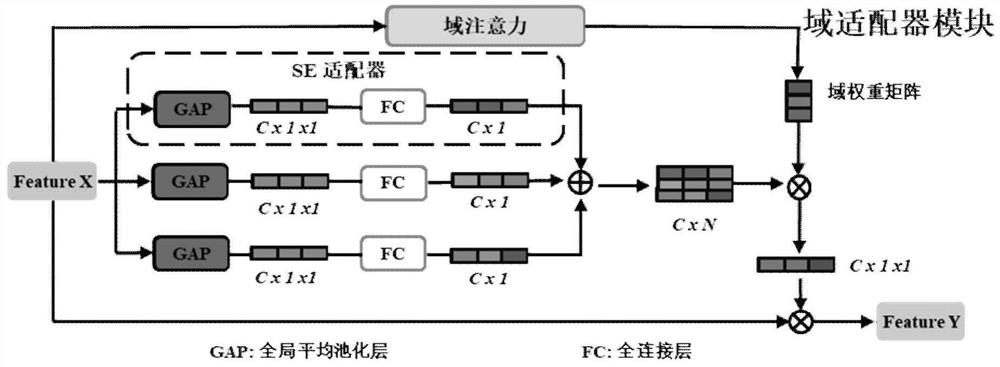

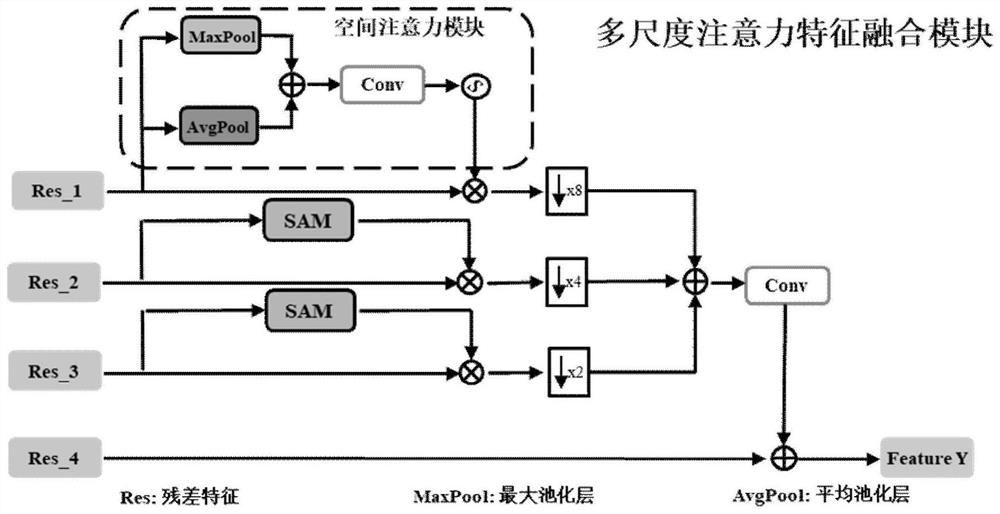

Face anti-fraud method based on cross-domain feature alignment network

PendingCN114120401AEffective complementaryDiscriminatingData processing applicationsCharacter and pattern recognitionCharacteristic spaceNetwork model

The invention provides a face anti-fraud method based on a cross-domain feature alignment network, and belongs to the technical field of mode recognition. The method comprises the following steps: step 1, taking ResNet18 as a basic feature generation model, and designing an improved feature generation network in order to relieve domain difference and enhance deep feature representation; and step 2, in order to explore multi-granularity feature alignment to improve generalization ability for unknown target scenes, the invention provides a multi-granularity feature alignment network to perform local region and global image feature alignment. And 3, in order to reduce the intra-class distance and increase the inter-class distance at the same time, total loss is adopted to calculate the classification loss of the network, and a final network model is obtained through iterative adversarial training and parameter updating. Under the condition that a small amount of calculation is increased, the domain difference is effectively relieved, meanwhile, the feature expression ability is enhanced, a more robust and generalized feature space is captured, and a clearer classification boundary is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

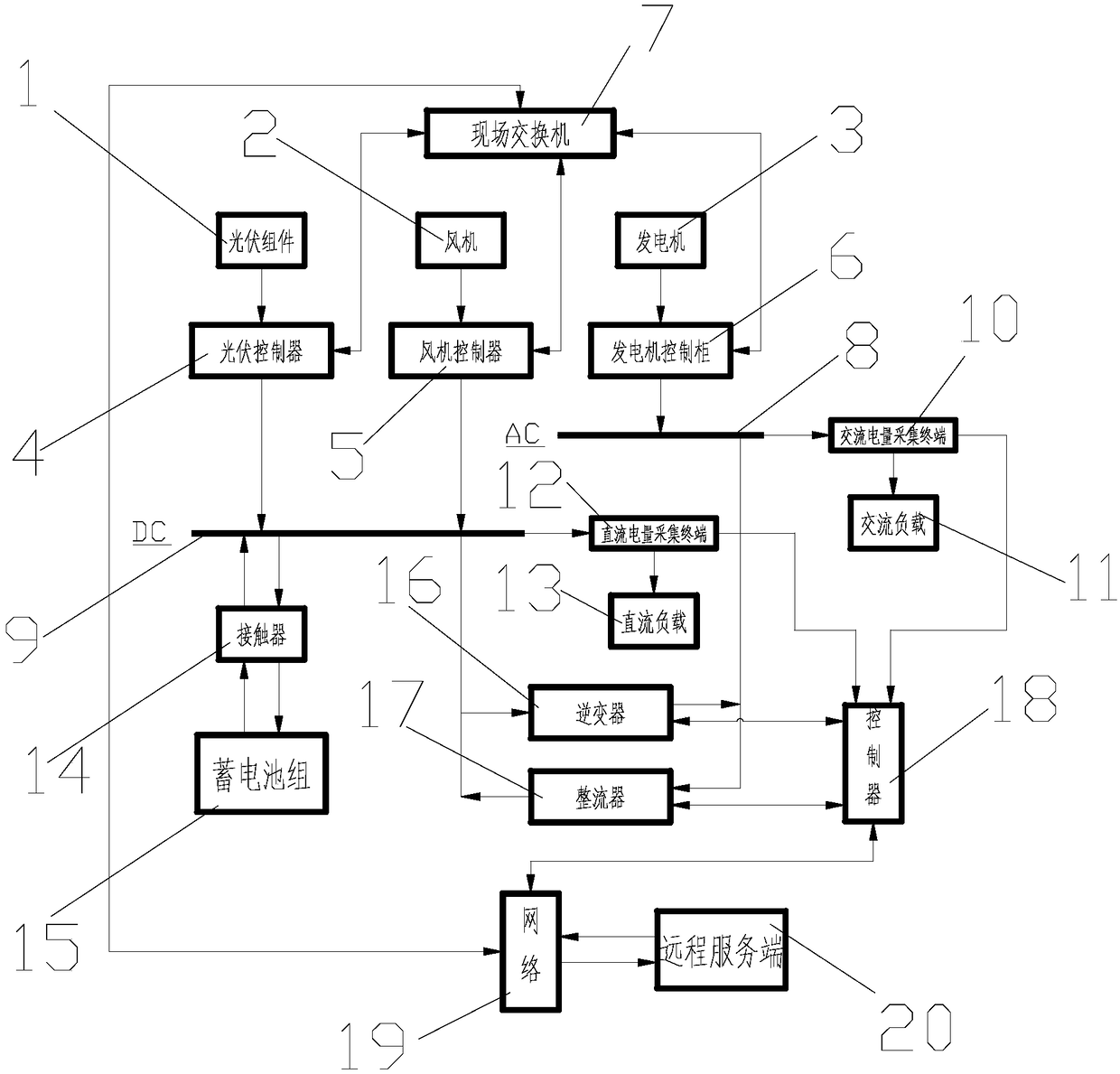

Micro grid based integrated energy development system and method

InactiveCN108695895AEnable remote viewingEasy to controlSingle network parallel feeding arrangementsEnergy storageSystems designEngineering

The invention discloses a micro grid based integrated energy development system and method. The system comprises a photovoltaic assembly, a blower fan, a generator, a photovoltaic controller, a blowerfan controller, a generator control cabinet, an onsite switch, an AC bus, a DC bus, an AC electric quantity collection terminal, an AC load, a DC electric quantity collection terminal, a DC load, a contactor, a storage battery pack, an inverter, a rectifier, a controller, a network and a remote server. The system and method have the advantages that the system is designed reasonably, the AC and DCelectric quantity collection terminal can collect electric quantities used in the AC and DC loads respectively, AC and DC power utilization conditions can be provided effectively, and reference is provided for start / stop of the inverter and the rectifier.

Owner:山西清新科技股份有限公司

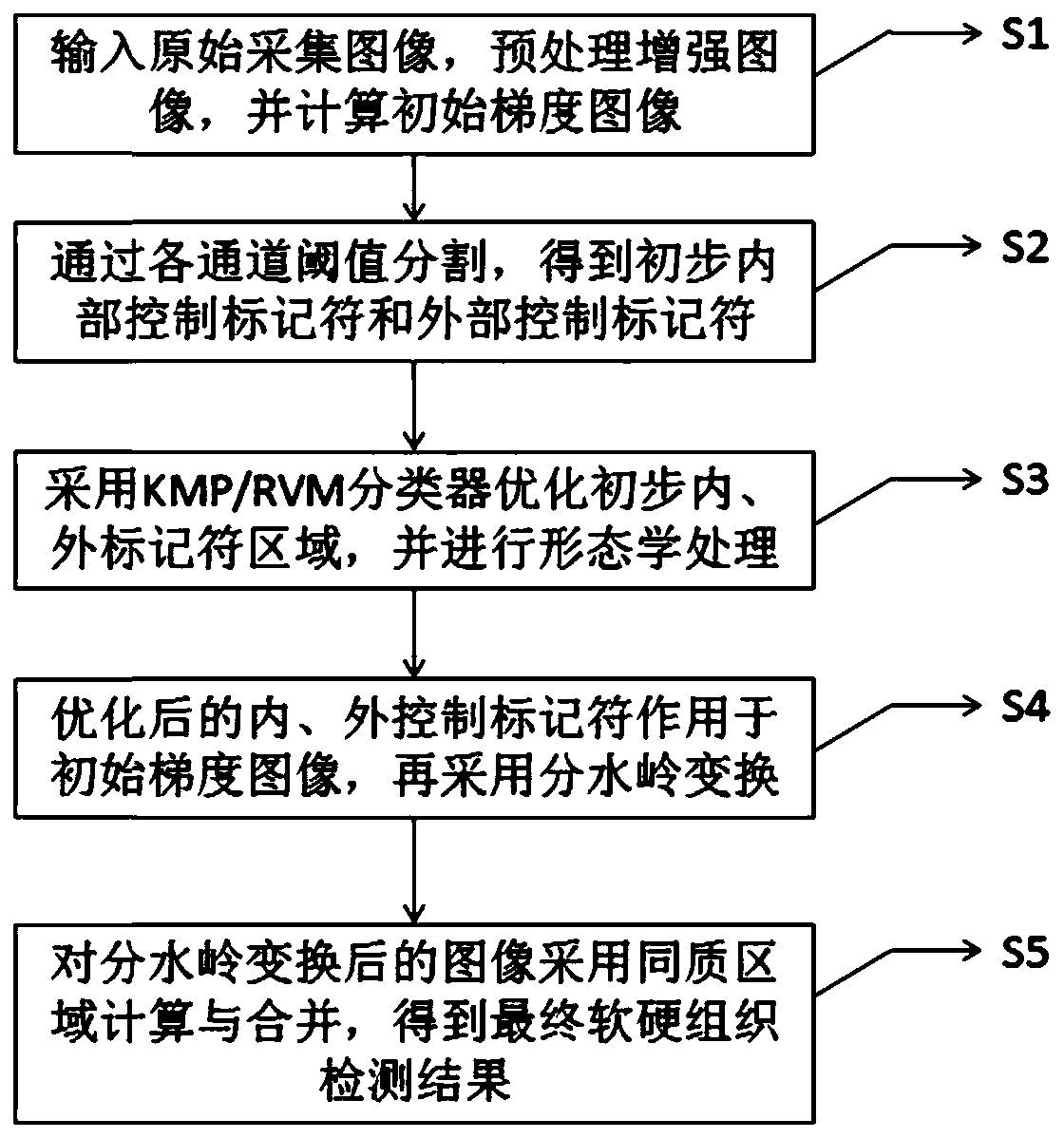

Tooth image soft and hard tissue detection method

ActiveCN111008949AEffective complementaryImprove detection efficiencyImage enhancementImage analysisSource imageThresholding

The invention discloses a tooth image soft and hard tissue detection method. The method comprises the following steps: acquiring an enhanced image of a tooth source image; obtaining an adjusted initial gradient image according to a gradient calculation result and the enhanced image; obtaining a preliminary internal control marker set and a preliminary external control marker set according to a threshold segmentation rule based on each color channel of the tooth source image; obtaining an optimized internal control marker set and an optimized external control marker set according to KMP kernelmatching pursuit or an RVM correlation vector machine algorithm based on the preliminary internal control marker set and the preliminary external control marker set; obtaining a final optimized internal control marker set and a final optimized external control marker set according to a mathematical morphology algorithm; applying the final optimized internal control marker set and the external control marker set on the initial gradient image to obtain a modified gradient image; and finally obtaining images of a soft tissue region and a hard tissue region of the tooth body according to a watershed transformation method and the combination of the homogeneous regions.

Owner:苏州喆安医疗科技有限公司

Method and device for segmenting characters from video image

InactiveCN101599124BGood segmentation effectQuick splitCharacter and pattern recognitionPattern recognitionAnalysis method

The invention discloses a method for segmenting characters form a video image, which comprises the following steps: positioning an original character image in the video image; extracting character stroke information from the original character image, obtaining a binary stroke image of the original character image according to the character stroke information; establishing a color model aiming at a character region in the binary stroke image, extracting a color layer image of the character region according to the color model; and removing excess backgrounds and noise by using an improved connection body analysis method with stroke masks so as to obtain the target character image. The invention has little computation and good property and can rapidly and accurately segment the characters from the video image of the complex backgrounds without machine learning.

Owner:HANVON CORP

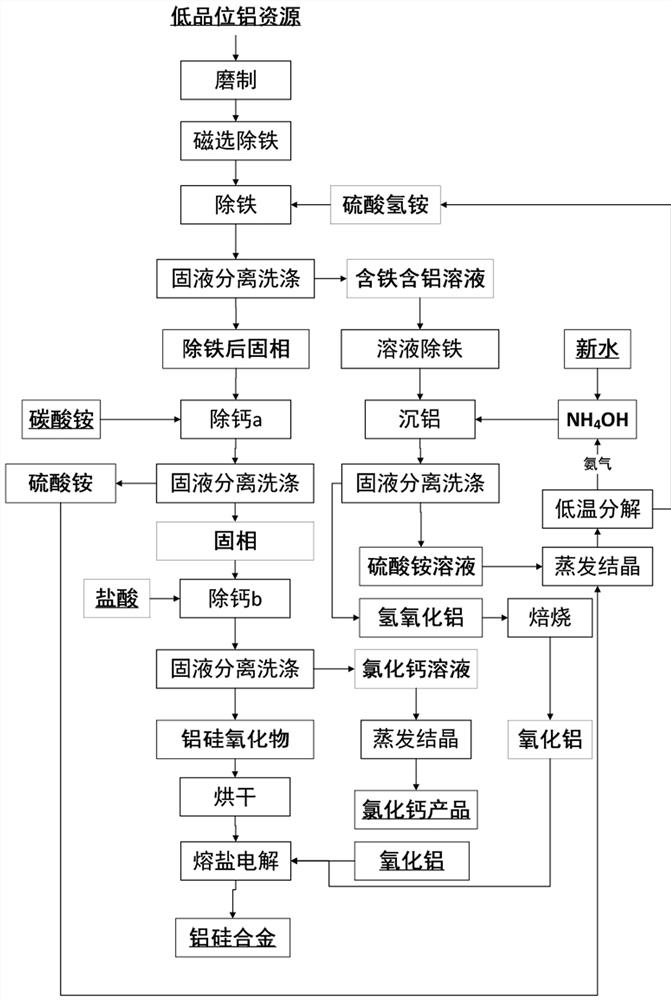

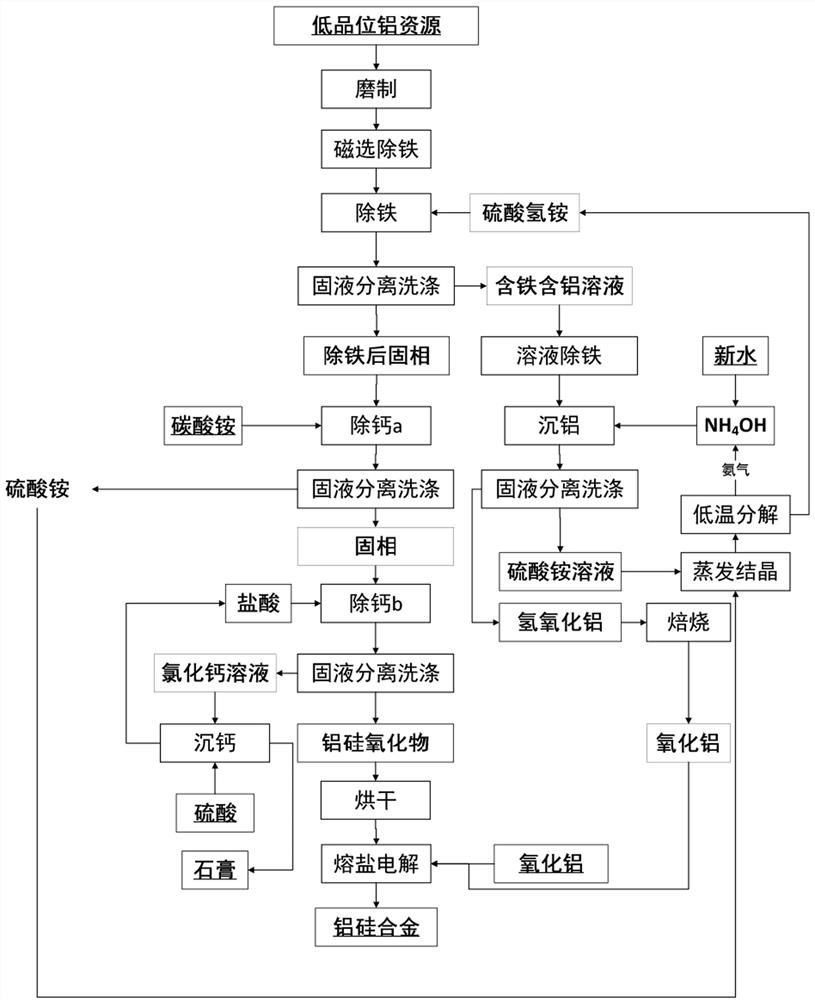

A method for preparing aluminum-silicon alloys from low-grade aluminum resources

ActiveCN109811371BEfficient recyclingEffective complementaryMagnetic separationProcess efficiency improvementHydrogen SulfateElectrolysis

The invention belongs to a method for comprehensive utilization of resources, in particular to a method for preparing an aluminum-silicon alloy from low-grade aluminum resources. The aluminum-silicon alloy is prepared through the steps of preliminary iron removal by magnetic separation, iron removal by ammonium bisulfate, calcium removal, and molten salt electrolysis. Iron is removed through ammonium bisulfate circulation, while the lost alumina is effectively recovered, ammonium bisulfate is recycled, and the cost is low; there is no discharge of waste residue and wastewater in the process, which is more environmentally friendly. The purpose of the present invention is to remove iron oxide and calcium oxide, and the cost is much lower than that of separately purifying aluminum oxide and silicon oxide. The reaction system of the invention is a weak acid and alkaline system, and the equipment is easy to solve, which is beneficial to industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com