Superhard constructions and methods of making same

A technology of structure and superhard phase, which is applied in the direction of manufacturing tools, earthwork drilling, abrasives, etc., and can solve the problems of reduced impact resistance of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

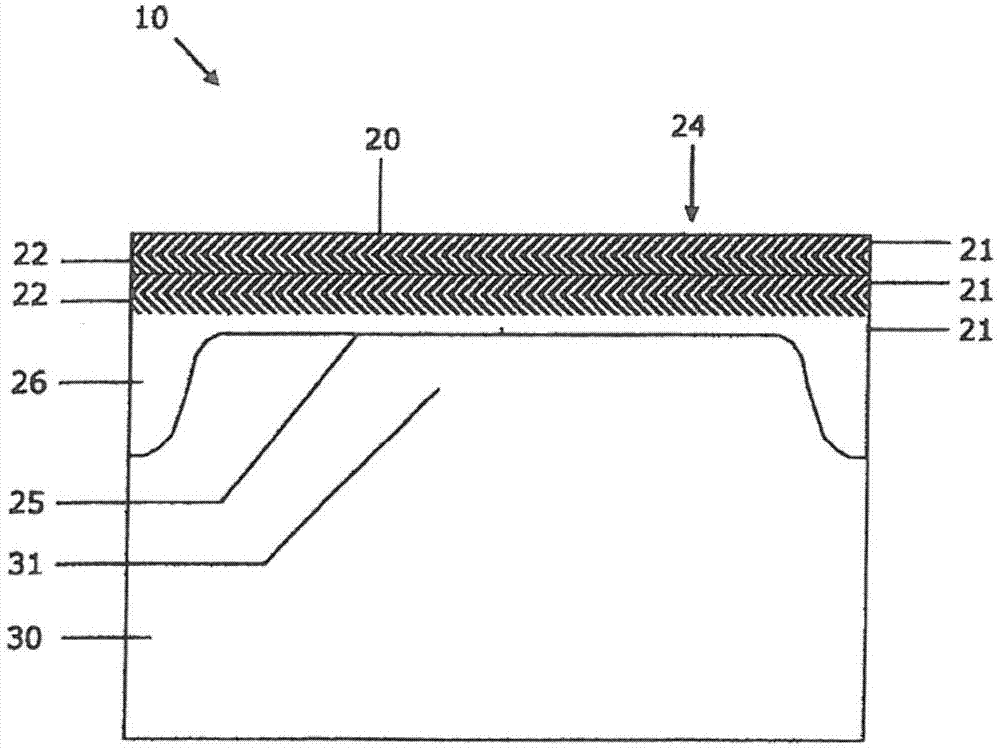

[0141] Submicron cobalt powder in an amount sufficient to obtain 2% by mass in the final diamond mixture used to form one type of layer was first deagglomerated in a methanol slurry in a ball mill with WC grinding media for 1 hour. A fine fraction of diamond powder having an average particle size of 2 μm is then added to the slurry in an amount to obtain 10% by mass in the final mixture. Additional milling media was introduced and additional methanol was added to obtain a suitable slurry; the resultant was milled for an additional hour. A coarse fraction of diamond with an average particle size of about 20 μm is then added in an amount to obtain 88% by mass in the final mixture for forming one type of layer. The slurry was replenished with additional methanol and grinding media, and then ground for an additional 2 hours. The slurry is removed from the ball mill and dried to obtain a diamond powder mixture.

[0142] The diamond powder mixture is then placed into a suitable HP...

Embodiment 2

[0144] Submicron cobalt powder in an amount sufficient to obtain 2.4% by mass in the final diamond mixture for forming one type of layer was first deagglomerated in a methanol slurry in a ball mill with WC grinding media for 1 hour. A fine fraction of diamond powder with an average particle size of 2 μm was then added to the slurry in an amount to obtain 29.3% by mass in the final mixture for forming one type of layer. Additional milling media was introduced and additional methanol was added to obtain a suitable slurry; the resultant was milled for an additional hour. A coarse fraction of diamond with an average particle size of about 20 μm is then added in an amount to obtain 68.3% by mass in the final mixture for forming one type of layer. The slurry was replenished with additional methanol and grinding media, and then ground for an additional 2 hours. The slurry is removed from the ball mill and dried to obtain a diamond powder mixture for forming one type of layer.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com