Integral multistage simultaneous nitrification and denitrification biological membrane system denitrification method and device

A technology of nitrification and denitrification and biofilm system, applied in the field of denitrification of integrated multi-stage simultaneous nitrification and denitrification biofilm system, can solve the problems of high energy consumption, complicated operation and maintenance, etc., and achieve convenient operation and management, simple operation and management, The effect of saving equipment cost and operation processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The application will be further described below in conjunction with the accompanying drawings and embodiments.

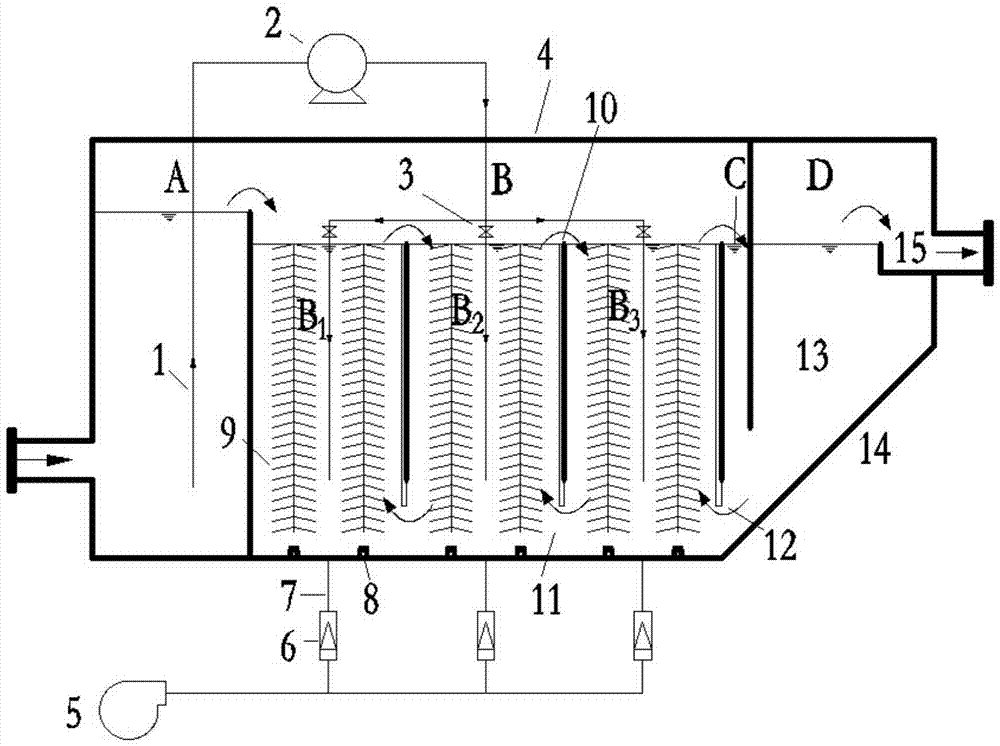

[0028] device see figure 1 , an integrated multi-stage simultaneous nitrification and denitrification biofilm system denitrification device provided by the present invention. Device 4, air pump 5, gas flow meter 6, gas delivery pipe 7, aeration head 8, filler 9, outflow port 10, return port 11, sludge return adjustable baffle plate 12, inclined plate sedimentation tank 13; Simultaneous nitrification and denitrification denitrification reactor 4 is sequentially composed of adjustment area A, multi-stage simultaneous nitrification and denitrification area B, diversion area C, and precipitation area D from left to right; the segmented water inlet pipe 1 is set in the adjustment tank At the bottom, the multi-stage simultaneous nitrification and denitrification area is composed of three reaction tanks forming a multi-stage series structure. Two adjacent reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com