Spinning rubber tube

A rubber hose and natural rubber technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., to achieve high strength, easy to use, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific embodiments of the present invention will be briefly described below in conjunction with the drawings.

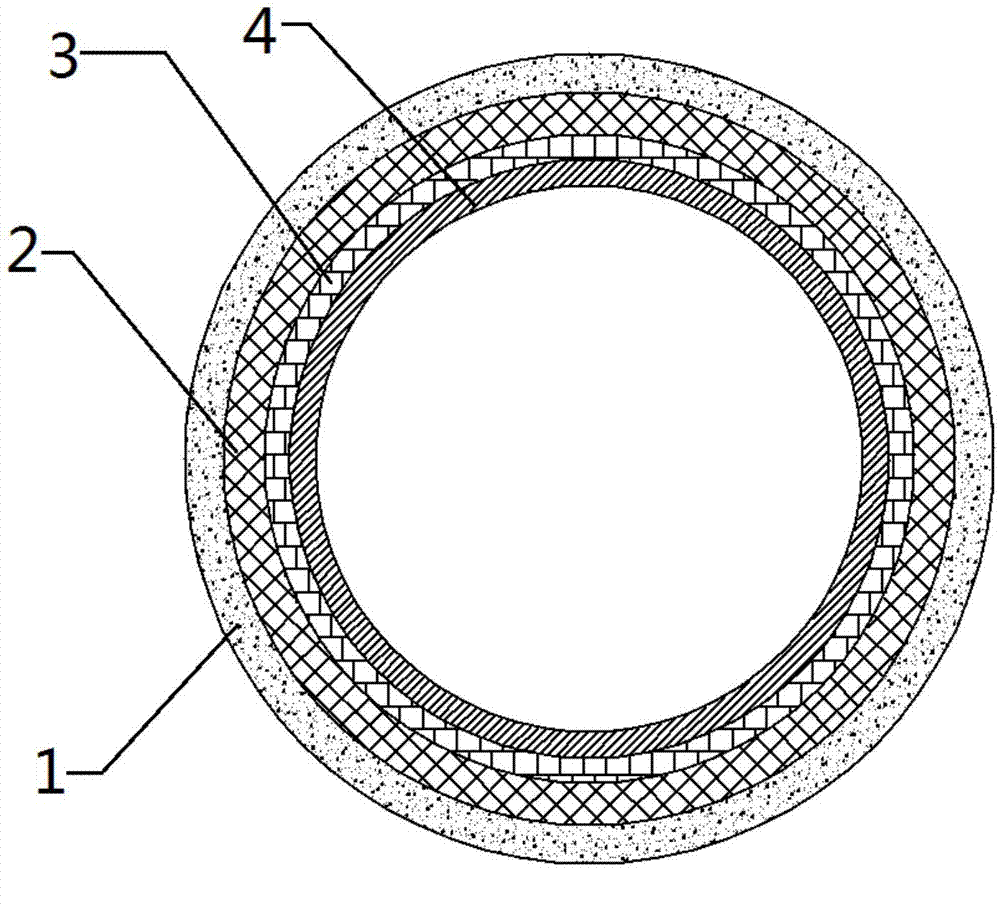

[0009] As shown in the figure, a spinning hose is formed by sequentially bonding an outer layer 1, a functional layer, and an inner layer 4. The outer layer 1 is a natural rubber layer, and the inner layer 4 is a fluorine rubber layer; The functional layer is composed of a nitrile rubber layer 2 and a silicone rubber layer 3 from the outside to the inside.

[0010] The surface of the non-slip layer 2 is wavy.

[0011] The working process of this example: when the spinning hose is used for spinning, the outer layer 1 uses a natural rubber layer, which provides good softness and will not affect the spinning work. At the same time, the inner layer The fluorine rubber layer of 4 provides air permeability resistance for the hose, the nitrile rubber layer 2 of the functional layer provides high wear resistance, and the silicone rubber layer 3 provides chemical inert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com