Novel throttle valve

A throttle valve and a new type of technology, applied in the field of throttle valve, can solve the problems of slow pressure adjustment process, reduced throttle valve response speed, fluid leakage, etc., to increase the service life, increase the flow area, and reduce the back pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

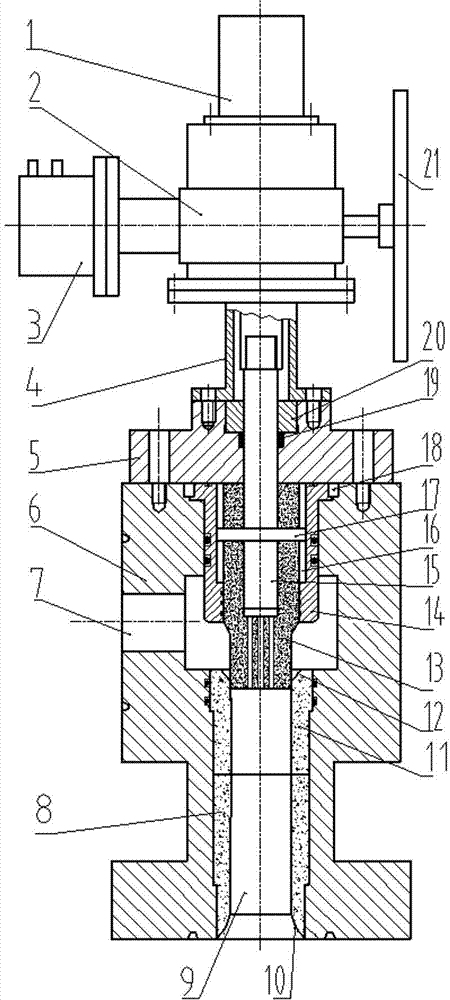

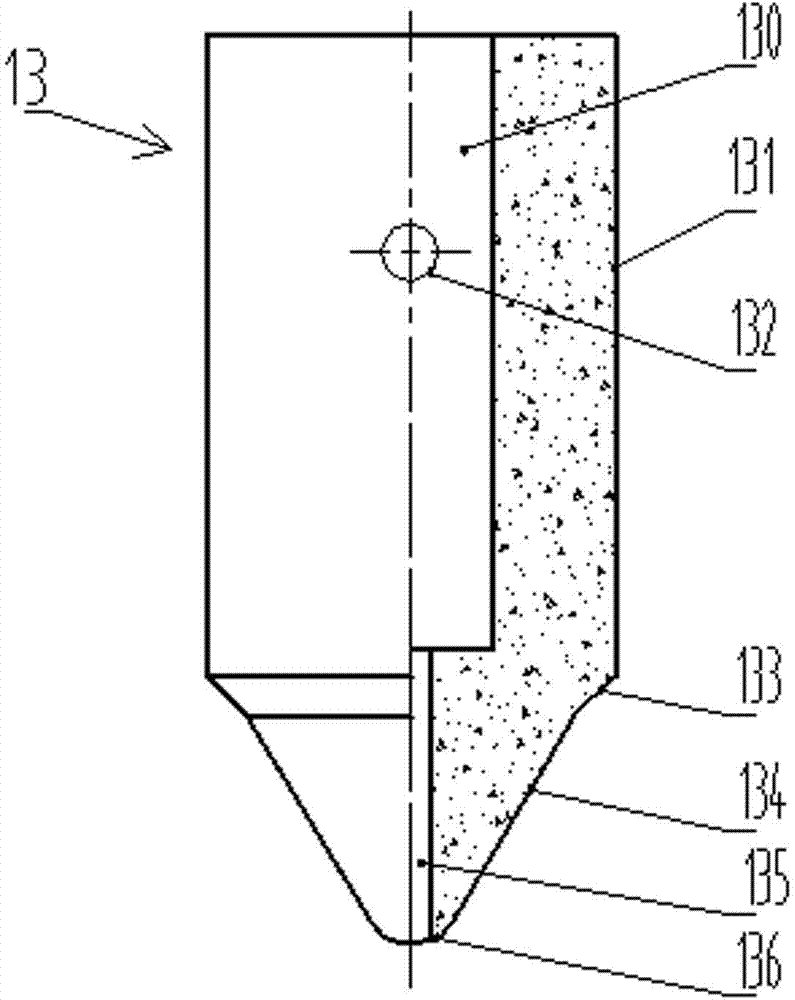

[0028] Refer to attached Figure 1 to Figure 6 , a new throttle valve includes a driver 2 , a valve cover 5 , a valve stem 15 , a valve body 6 , a valve core 13 , a valve seat 11 and a valve body bushing 8 . The driver 2 is an elevator composed of a worm gear pair and a screw pair. One end of the worm of the driver 2 is connected to the hydraulic motor 3, and the other end is installed with a handwheel 21. The upper end of the driver 2 is installed with a displacement sensor 1. The lower end of the driver 2 is connected to the support cylinder 4, which 4 The lower end is connected to the valve cover 5, the valve cover 5 is connected to the upper end of the valve body 6, the lower end of the screw rod of the driver 2 is connected to the valve stem 15, and the valve stem 15 and the valve core 13 are connected together through the connecting pin 17; the upper part of the valve body 6 is processed The anti-rotation barrel 14 is inserted into the hole, and the anti-rotation pin 18 ...

Embodiment 2

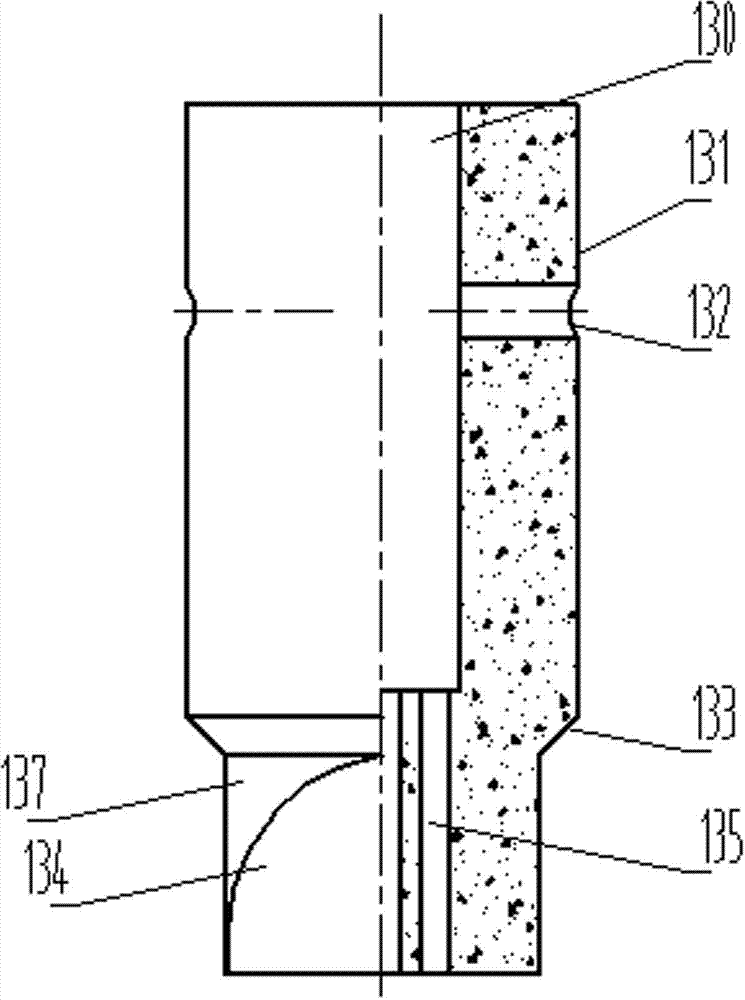

[0034]A new type of throttle valve, including a driver 2, a valve cover 5, a valve stem 15, a valve body 6, a valve core 13 and a valve seat 11, wherein: the lower part of the driver 2 is connected to the valve cover 5, and the connection between the valve cover 5 and the valve body 6 The upper end surface is connected, the lower end of the screw rod of the driver 2 is connected to the valve stem 15, and the lower part of the valve stem 15 is connected to the valve core 13; The valve core 13 is inserted into the anti-rotation cylinder 14, and forms a circumferential locking and axial sealing sliding fit with the anti-rotation cylinder 14; the side and lower part of the valve body 6 are respectively processed with inlet channels 7 and The outlet channel 9 and the valve seat 11 are installed in the outlet channel 9, and form an axial insertion fit with the upper valve core 13); the upper part of the valve core 13 is a cylinder, and the lower end is symmetrically processed with tw...

Embodiment 3

[0036] On the basis of above-mentioned embodiment 2, also include:

[0037] The driver 2 is an elevator composed of a worm gear pair and a screw pair. One end of the worm of the driver 2 is connected to the drive motor 3, and the other end is installed with a handwheel 21. A displacement sensor 1 is installed on the top of the driver 2; the lower part of the driver 2 passes through the support tube 4. Connect the bonnet 5; the anti-rotation cylinder 14 and the valve body 6 are circumferentially locked by the anti-rotation pin 18; the valve stem 15 and the valve core 13 are connected by a connecting pin 17; the valve core 13 and the anti-rotation The rotating cylinders 14 form a circumferential locking with the inner groove 16 provided on the anti-rotating cylinder 14 through the connecting pins 17 . The driving motor 3 adopts a piston-type hydraulic cylinder structure

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com