Calcium content determination method for low-calcium aluminum ferromanganese

A low-calcium-aluminum-manganese-ferromanganese, calcium content technology, which is applied in the direction of chemical analysis by titration, can solve the problems of low-cost, rapid and accurate measurement, high instrument cost, etc., and achieve stable titration results, simple equipment requirements, and pharmaceuticals The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

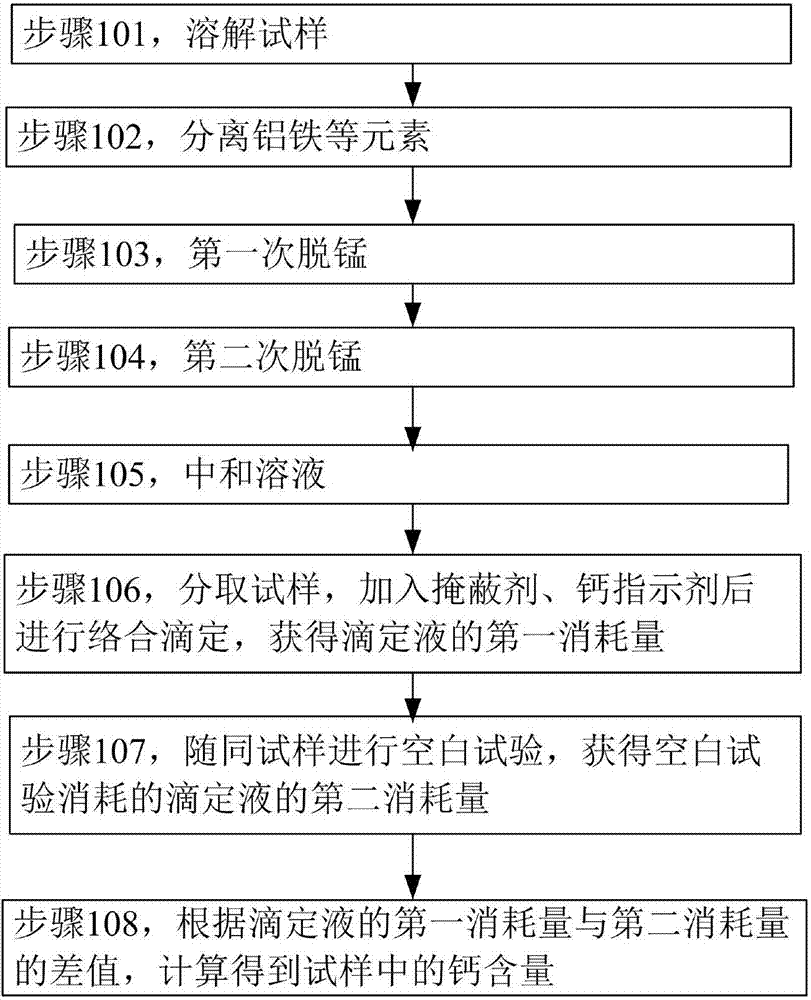

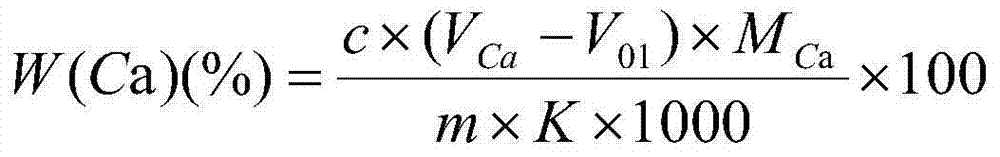

[0023] Existing methods need to use large-scale instruments to determine the calcium content in low-calcium aluminum-manganese-iron, which has strict requirements on the testing environment, which directly leads to high testing costs, it is not easy to perform testing near the site, and the testing process is too complicated. In order to achieve quick and easy determination, the present invention proposes a new idea of determining the calcium content in low-calcium aluminum-manganese-iron. After dissolving the sample with hydrochloric acid-hydrogen peroxide, the aluminum and iron are separated by ammonia, and ammonium persulfate is used for oxidation The manganese removal forms a colloidal precipitate. After the precipitate is separated by filtration, the mangane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com