Semiconductor element, semiconductor device, method for manufacturing semiconductor element, and method for manufacturing semiconductor device

A semiconductor and component technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of hindering the operation of components, not yet practical, and low resistance, and achieve the effect of improving ESD resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

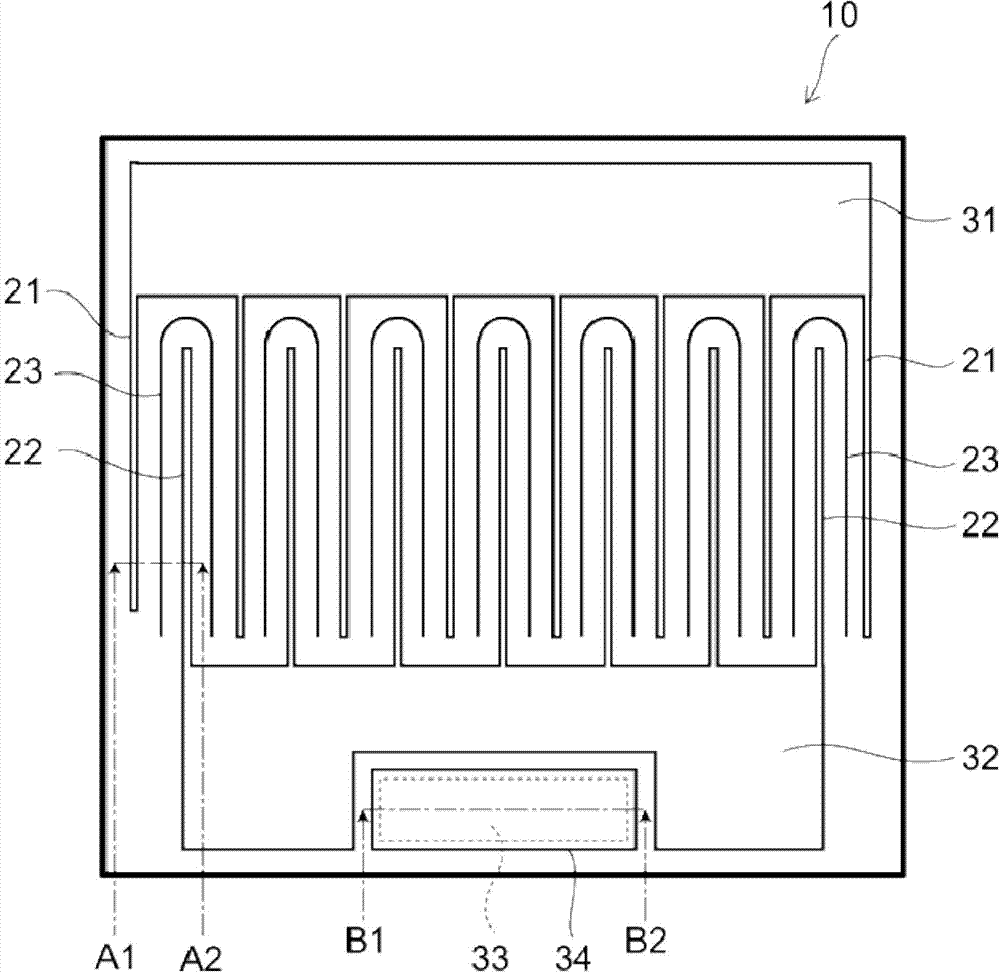

[0029] figure 1 It is a plan view schematically showing the semiconductor element of the first embodiment. In addition, in this plan view, the insulating layer 19 is omitted.

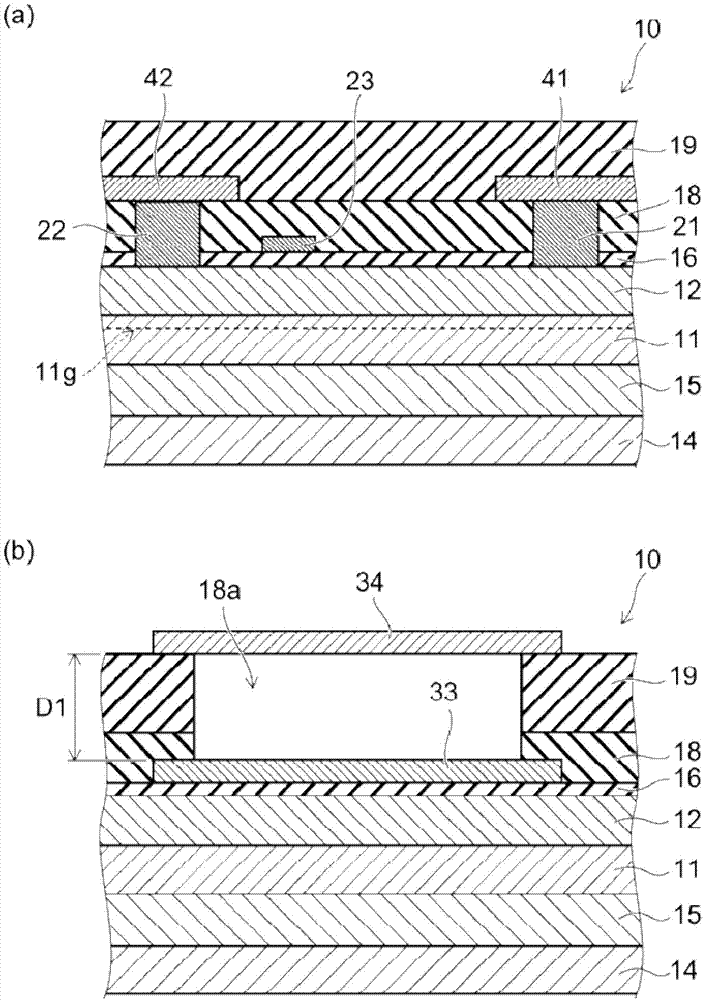

[0030] figure 2 (a) and figure 2 (b) is a partial cross-sectional view schematically showing a part of the semiconductor element of the first embodiment.

[0031] figure 2 (a) Schematic representation figure 1 A1-A2 line section. figure 2 (b) Schematic representation figure 1 B1-B2 line section.

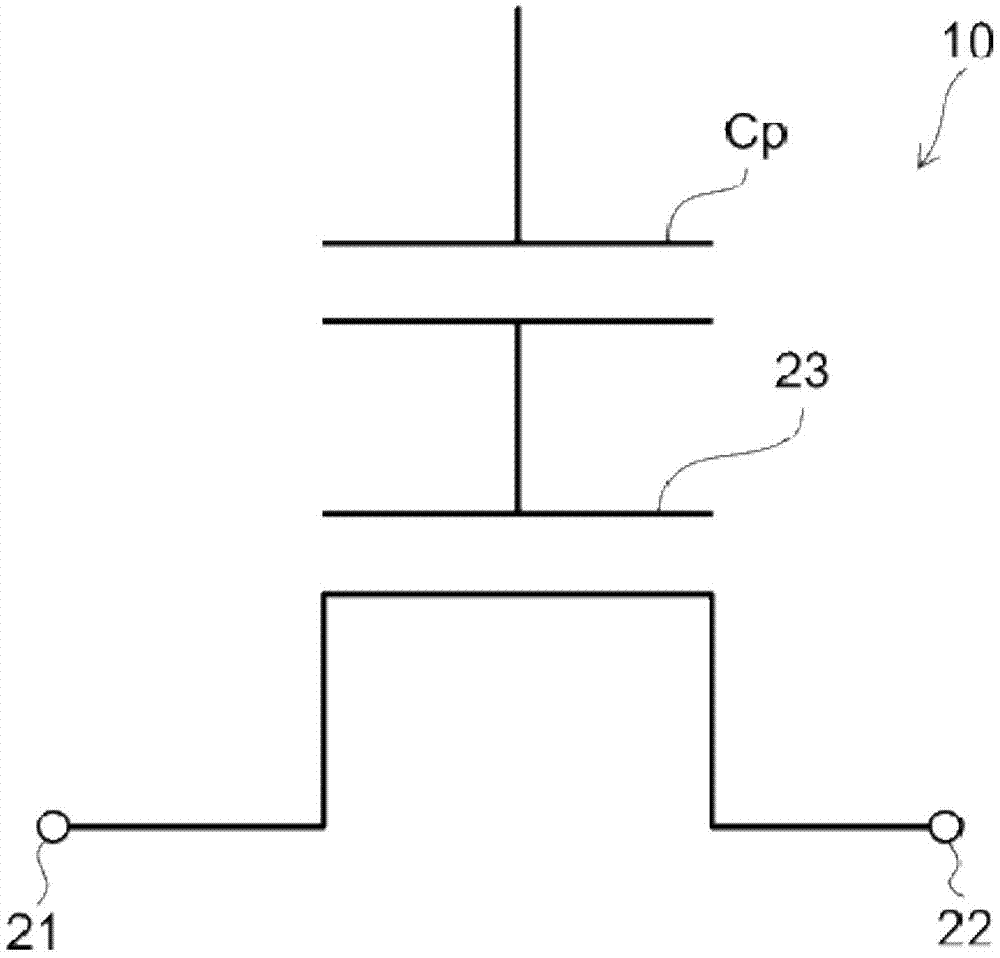

[0032] Such as figure 1 , figure 2 (a) and figure 2 As shown in (b), the semiconductor element 10 has a first semiconductor layer 11, a second semiconductor layer 12, a substrate 14, a base layer 15, a gate insulating film 16, an insulating layer 18 and an insulating layer 19, and a drain electrode 21 (first electrode), source electrode 22 (second electrode), gate electrode 23 (gate electrode), drain junction region 31, source junction region 32, gate junction region 33 (junction region), cond...

no. 2 approach

[0083] Figure 8 (a) and Figure 8 (b) is a schematic diagram showing the semiconductor element of the second embodiment.

[0084] Figure 8 (a) is a partial cross-sectional view schematically showing a part of the semiconductor element 110 .

[0085] Figure 8 (b) is an equivalent circuit diagram schematically showing the semiconductor element 110 .

[0086] Such as Figure 8 As shown in (a), the semiconductor element 110 further includes a resistor 35 . The semiconductor element 110 includes, for example, a plurality of resistors 35 . The resistor 35 is disposed between the gate bonding region 33 and the conductor 34 . The resistor 35 is electrically connected to the gate bonding region 33 and the conductor 34 respectively. Resistor 35 is in contact with gate land 33 and conductor 34 , for example. That is, in the semiconductor element 110 , the conductor 34 is electrically connected to the gate land 33 via the resistor 35 . The resistor 35 is, for example, a metal...

no. 3 approach

[0097] Figure 10 It is a plan view schematically showing the semiconductor element of the third embodiment.

[0098] Figure 11 (a) and Figure 11 (b) is a partial cross-sectional view schematically showing a part of the semiconductor element of the third embodiment.

[0099] Figure 11 (a) Schematic representation Figure 10 The C1-C2 line section.

[0100] Figure 11 (b) Schematic representation Figure 10 D1-D2 line section.

[0101] Such as Figure 10 , Figure 11 (a) and Figure 11 As shown in (b), in the semiconductor element 120 , the opening 18 a and the conductor 34 are provided at positions that do not overlap with the gate bonding region 33 . In the semiconductor element 120 , the opening 18 a and the conductor 34 do not face the gate bonding region 33 .

[0102] In the semiconductor element 120 , the conductor 34 is electrically connected to the gate land 33 via the wiring 36 . In addition, in the semiconductor element 120 , the conductive film 38 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com