Preparation method of reverse polarity AlGaInP red light LED (Light-Emitting Diode) chip

An LED chip, reverse polarity technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as pollution, and achieve the effect of avoiding pollution, simplifying production processes, and avoiding missing electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

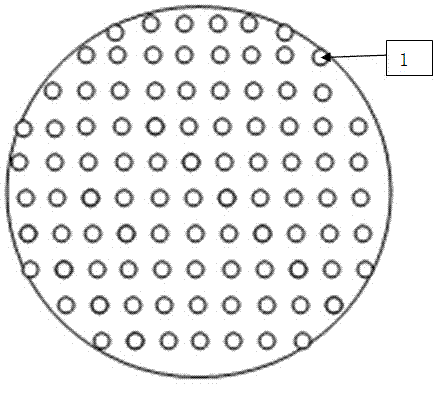

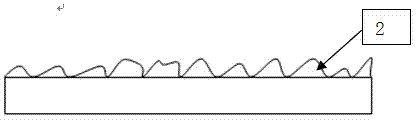

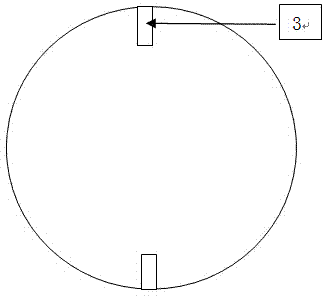

Image

Examples

Embodiment Construction

[0023] The preparation method of the GaAs-based light-emitting diode chip of the present invention is to add a step of removing the residual metal film layer on the edge of the wafer after the GaAs substrate is stripped in the existing substrate stripping process, by using tweezers to adjust the position of the wafer, and using a single blade The blade cooperates to remove all the metal film layer remaining on the edge of the wafer. It is ensured that the wafer will not be polluted by metal powder when the N-type electrode is evaporated for the first time, resulting in missing electrodes. When making the registration mark window, the method of sticking high-temperature-resistant tape on the window area is cleverly adopted, and the production of the overlay registration mark window and the evaporation of the N-type electrode are carried out simultaneously, which simplifies the chip production process. The specific process is as follows:

[0024] (1) A layer of TiAu film is eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com