Transparent organic electroluminescent device and preparation method thereof

A luminescent and electromechanical technology, which is applied in the manufacture of organic semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve the problems of large difference in light extraction efficiency and affect the visual effect of transparent organic electroluminescent devices, so as to improve the visual effect effect, reducing the difference in light extraction efficiency, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

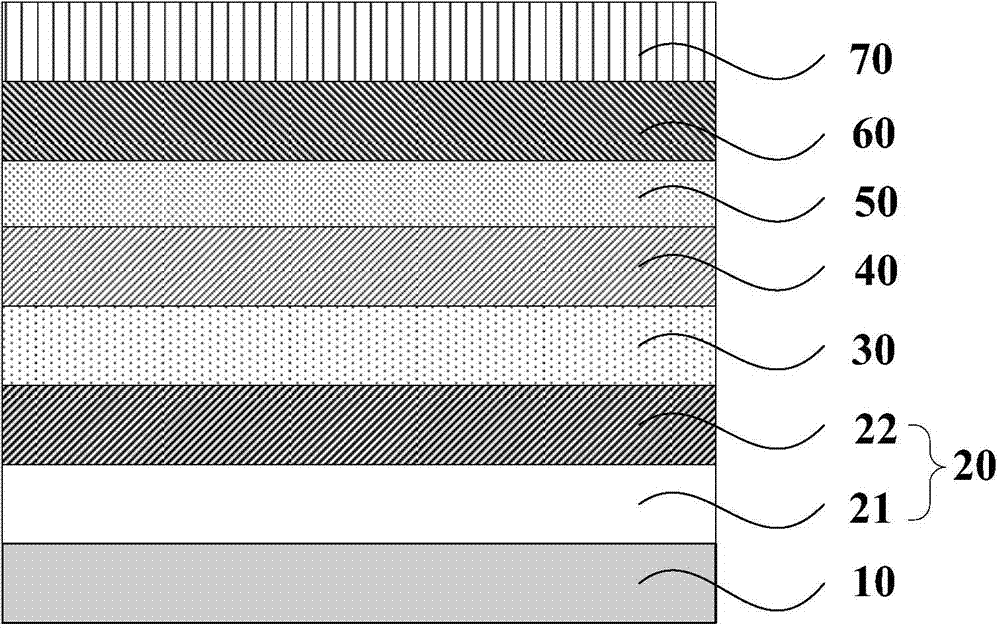

[0045] A method for preparing a transparent organic electroluminescent device, comprising the steps of:

[0046] a) Preparation of the anode: Take the glass substrate, wash it with detergent, deionized water, acetone and ethanol in sequence, and use an ultrasonic cleaning machine to clean it. Each washing is performed for 5 minutes and stopped for 5 minutes. Repeat respectively. 3 times, and then dry it in an oven for use; prepare an anode on the treated glass substrate surface, the anode includes a first anode layer and a second anode layer, and first adopts a method of spin coating on the surface of the glass substrate Prepare the first anode layer, and then prepare the second anode layer on the surface of the first anode layer by vacuum evaporation; the material of the first anode layer is (3-mercaptopropyl) trimethoxysilane, the thickness is 4nm, spin The rotating speed of the coating is 2000rpm; the material of the second anode layer is magnesium-aluminum alloy (mass rati...

Embodiment 2

[0054]A method for preparing a transparent organic electroluminescent device, comprising the steps of:

[0055] a) Preparation of the anode: Take the glass substrate, wash it with detergent, deionized water, acetone and ethanol in sequence, and use an ultrasonic cleaning machine to clean it. Each washing is performed for 5 minutes and stopped for 5 minutes. Repeat respectively. 3 times, and then dry it in an oven for use; prepare an anode on the treated glass substrate surface, the anode includes a first anode layer and a second anode layer, and first adopts a method of spin coating on the surface of the glass substrate Prepare the first anode layer, and then prepare the second anode layer on the surface of the first anode layer by vacuum evaporation; the material of the first anode layer is (3-mercaptoethyl) trimethoxysilane, and the thickness is 2nm. The rotation speed of the spin coating is 5000rpm; the material of the second anode layer is lithium-aluminum alloy (mass rati...

Embodiment 3

[0063] A method for preparing a transparent organic electroluminescent device, comprising the steps of:

[0064] a) Preparation of the anode: Take the glass substrate, wash it with detergent, deionized water, acetone and ethanol in sequence, and use an ultrasonic cleaning machine to clean it. Each washing is performed for 5 minutes and stopped for 5 minutes. Repeat respectively. 3 times, and then dry it in an oven for use; prepare an anode on the treated glass substrate surface, the anode includes a first anode layer and a second anode layer, and first adopts a method of spin coating on the surface of the glass substrate Prepare the first anode layer, and then prepare the second anode layer on the surface of the first anode layer by vacuum evaporation; the material of the first anode layer is elemental barium (Ba), the thickness is 20nm, and the vacuum degree of vacuum evaporation used is 1×10 -5 Pa, the evaporation rate is The material of the second anode layer is (3-merca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com