Covalence triazine organic polymer visible-light-driven photocatalyst and preparing method and application thereof

A covalent triazine, polymer technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the sample containing metal inorganic salt impurities, preparation conditions Harsh and other problems, to achieve high practical value and application prospects, low production cost, good material stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

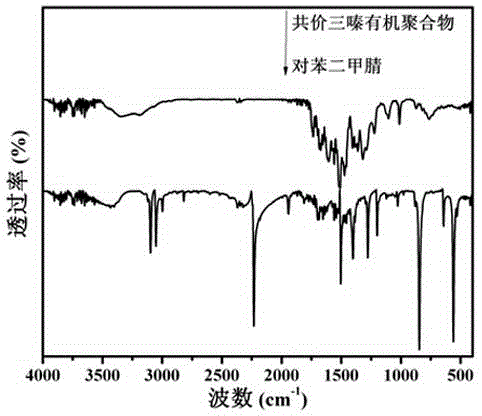

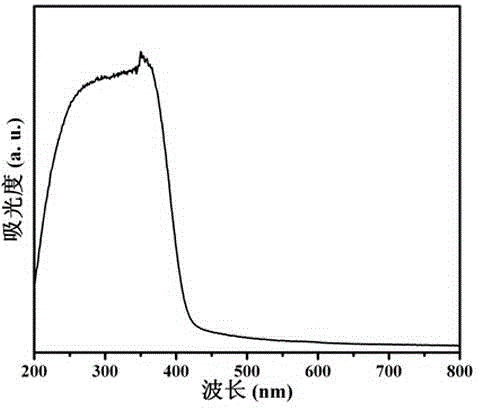

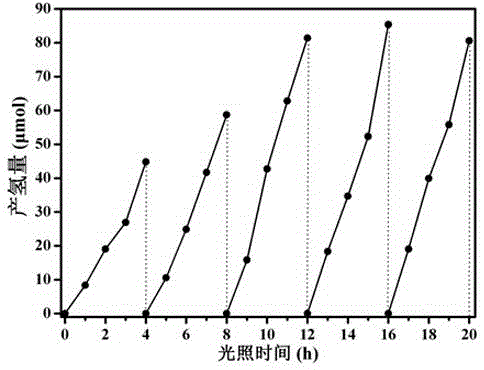

[0018] Under the condition of stirring at 0 °C, take 10 mL of trifluoromethanesulfonic acid and add it to 1.28 g of terephthalonitrile, replace the oil bath and heat up to 30 °C until the mixture becomes viscous and cannot be stirred. After standing for 3 days , rinsed and filtered with 40 mL of dichloromethane, then washed with ammonia water until the pH was greater than 7, then added 50 mL of ammonia water, stirred for 12 h, washed with water and centrifuged to pH 7, and finally washed and centrifuged with methanol once to obtain a solid precipitate; the above obtained The solid precipitated, refluxed with methanol at 90 °C for 12 h, then refluxed with dichloromethane at 65 °C for 12 h, and vacuum dried at 80 °C for 12 h, which was a covalent triazine organic polymer with a yield of 78.1 %.

Embodiment 2

[0020] Under the condition of stirring at 0 °C, take 10 mL of trifluoromethanesulfonic acid and add it to 1.28 g of terephthalonitrile, replace the oil bath and heat up to 30 °C until the mixture becomes viscous and cannot be stirred. After standing for 3 days , rinsed and filtered with 40 mL of dichloromethane, then washed with ammonia water until the pH was greater than 7, then added 50 mL of ammonia water, stirred for 12 h, washed with water and centrifuged to pH 7, and finally washed and centrifuged with methanol once to obtain a solid precipitate; the above obtained The solid precipitated, refluxed with methanol at 100 °C for 12 h, then refluxed with dichloromethane at 80 °C for 12 h, and vacuum dried at 80 °C for 12 h, which was a covalent triazine organic polymer with a yield of 60.9 %.

Embodiment 3

[0022] Under the condition of stirring at 0 °C, 40 mL of trifluoromethanesulfonic acid was added to 5.12 g of terephthalonitrile, the oil bath was replaced and the temperature was raised to 30 °C until the mixture became viscous and could not be stirred. After standing for 3 days , rinsed and filtered with 160 mL of dichloromethane, then washed with ammonia water until the pH was greater than 7, then added 200 mL of ammonia water, stirred for 12 h, washed with water and centrifuged to pH 7, and finally washed and centrifuged with methanol once to obtain a solid precipitate; the above obtained The solid precipitated, refluxed with methanol at 90 °C for 12 h, then refluxed with dichloromethane at 65 °C for 12 h, and vacuum dried at 80 °C for 12 h, which was a covalent triazine organic polymer with a yield of 60.5 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com