A kind of nonionic paraffin wax emulsion for wood modification and its preparation method and application

A technology of wood modification and paraffin wax emulsion, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of waste of raw materials, incompatibility with preservatives, uneven penetration, etc., to improve swelling resistance and enhance anticorrosion. performance, the effect of reducing moisture absorption deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

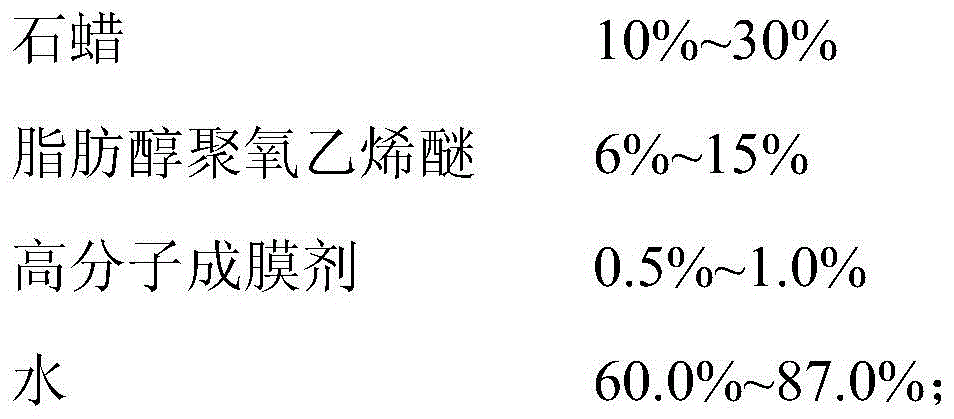

[0036] A preparation method of a non-ionic paraffin wax emulsion for wood modification, comprising the following steps:

[0037] Mix 400g of paraffin wax, 140g of fatty alcohol polyoxyethylene ether (compound of three C16-C18 fatty alcohol polyoxyethylene ethers with a degree of polymerization of 5, 20 and 40) and 10g of maleic anhydride copolymer and place it in an electric heating stirring tank , heat up to 85°C, start the mixer after the solid completely turns into a liquid, stir the mixture in the tank at a high speed of 400r / min, add 1450g of water with a temperature of 90°C at one time, and stir at a high speed of 400r / min The reaction was carried out for 30 min; then the stirring speed was reduced to 60 r / min, and the temperature of the system was lowered to 40° C. to obtain the nonionic paraffin wax emulsion for wood modification.

[0038] The particle size detection results of the non-ionic paraffin wax emulsion for wood modification prepared in this example are as fo...

Embodiment 2

[0042] A preparation method of a non-ionic paraffin wax emulsion for wood modification, comprising the following steps:

[0043] The paraffin wax, fatty alcohol polyoxyethylene ether and tung oil are mixed and placed in the reactor, the temperature is raised and stirred at a high speed of 200r / min. Then, the stirring speed was reduced to 60r / min, and the temperature of the system was lowered to 70°C to obtain the non-ionic paraffin wax emulsion for wood modification; the obtained emulsion by weight percentage contained the following components: paraffin wax 20%, fatty alcohol polyoxyethylene ether 10%, tung oil 1% and water 69%; wherein the fatty alcohol polyoxyethylene ether is three kinds of C16-C18 fatty alcohol polyoxyethylene with a degree of polymerization of 5, 20 and 40 Compounding of vinyl ethers.

Embodiment 3

[0045] A kind of preparation method of the nonionic paraffin wax emulsion that wood modification is used, comprises the following steps:

[0046] Mix paraffin wax, fatty alcohol polyoxyethylene ether and maleic anhydride copolymer and place it in the reactor, raise the temperature and stir at a high speed of 600r / min. After the temperature of the mixture reaches 85°C, add water at a temperature of 80°C, / min speed high-speed stirring reaction 20min, then the stirring speed is reduced to 20r / min, and the system is cooled to 30 ° C, to obtain the non-ionic paraffin emulsion for wood modification; the obtained emulsion contains the following components by weight percentage : Paraffin 30%, fatty alcohol polyoxyethylene ether 9%, maleic anhydride copolymer 0.5% and water 60.5%; wherein said fatty alcohol polyoxyethylene ether is three kinds of C16~ Compounding of C18 fatty alcohol polyoxyethylene ether.

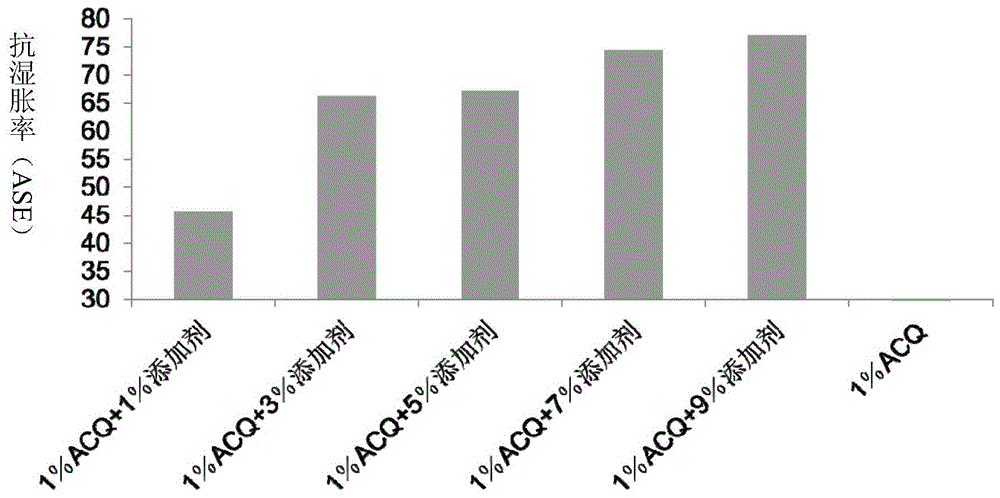

[0047] Application effect example:

[0048] (1) the nonionic paraffin emuls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com