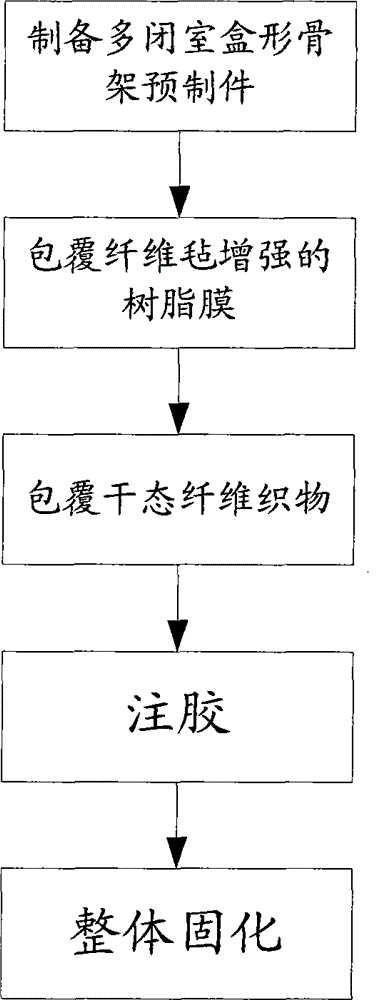

Composite multi-closed-chamber thick-walled box beam and integral moulding method

A composite material and integral molding technology, which is applied in the field of composite materials, can solve problems such as difficult to fully infiltrate, flow and consolidation of liquid molding resin system, long product preparation cycle, etc., to improve internal quality and integrity, and improve interface bonding Quality, the effect of improving the quality of interface connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

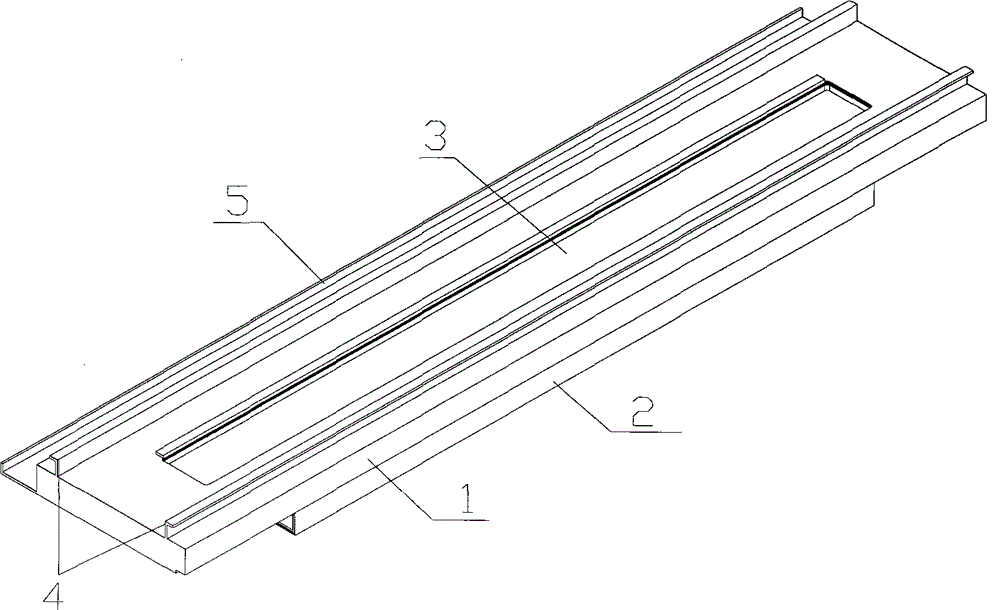

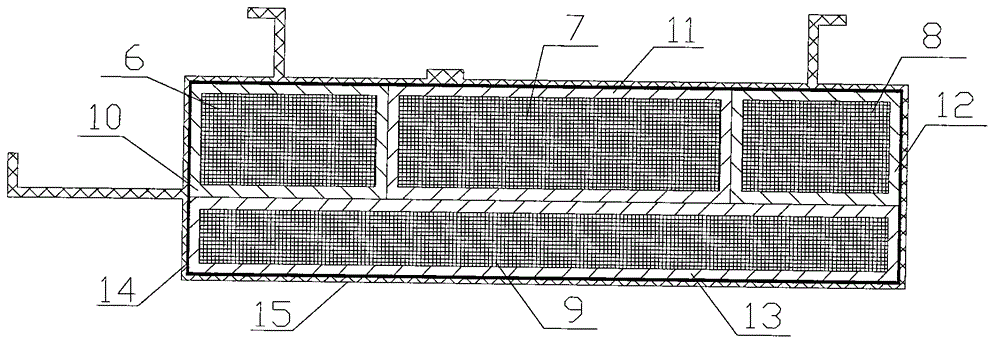

[0035] The multi-closed-chamber thick-walled box-shaped beam of the present invention mainly includes three parts: an inner skeleton, an outer skin and a foam core, wherein the foam core is the supporting structure of the inner skeleton during the molding process; the inner skeleton is composed of an independent single-closed chamber structure The resulting multi-closed thick-walled structure adopts fiber-reinforced material / prepreg resin system, which is prefabricated by vacuum bag or molding; the outer skin is a simple closed thin-walled structure, which uses fiber-reinforced material fabric / liquid molding resin system , after the resin is injected and filled, the inner skeleton and the outer skin are co-cured into an integral structure under a unified curing system.

[0036] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

[0037]In this embodiment, a composite material multi-closed thick-walled box-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com