Industrialization preparation method of mogroside V

A technology of mogroside and mogroside, applied in the field of industrialized extraction and preparation of mogroside V, can solve the problems of complicated process and low purity, and achieve the effects of improving safety, cheap solvent and saving cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

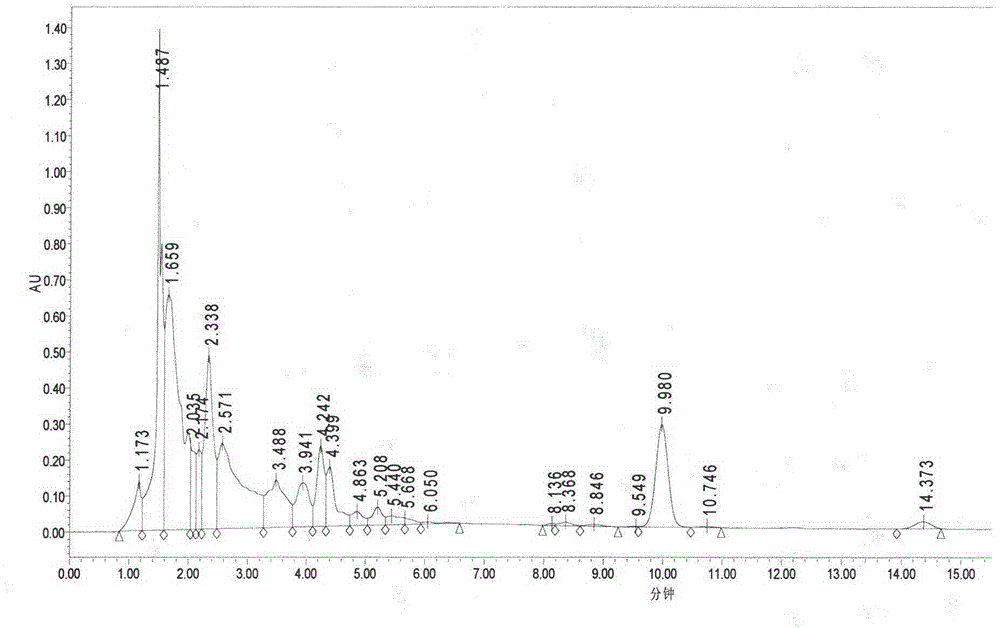

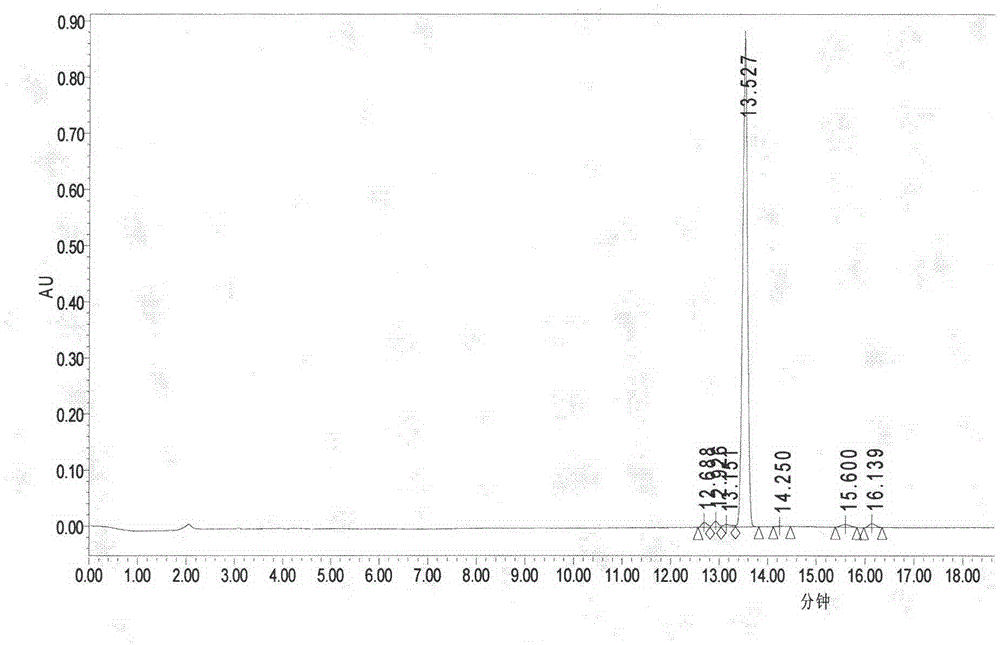

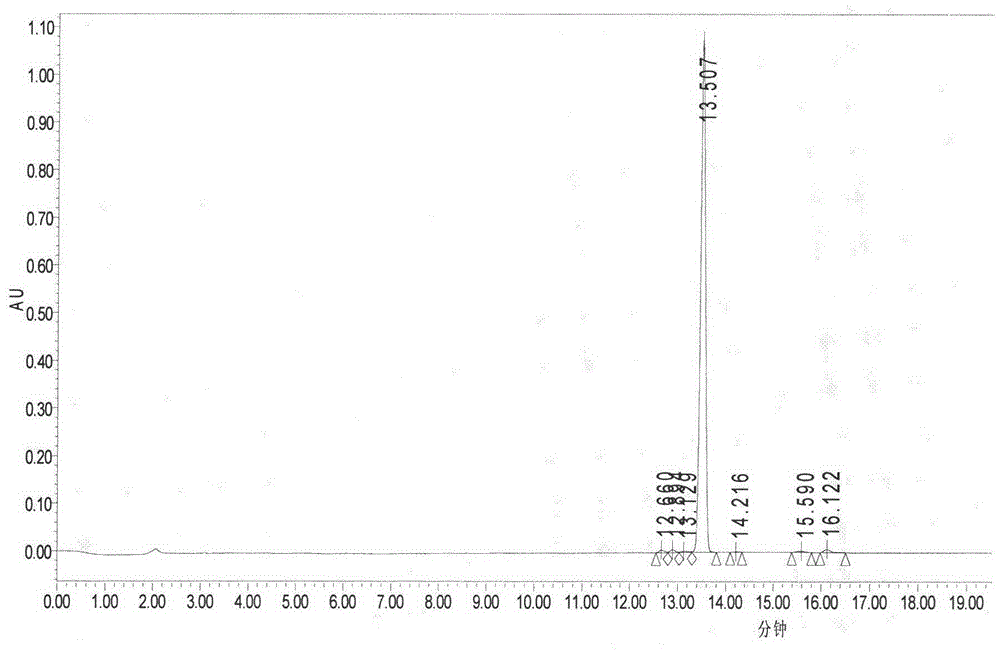

Image

Examples

Embodiment 3

[0029] Example 3——This example uses 22 μm n-octadecyl reverse-phase silica particles, and the rest of the process is the same as in Example 2, and the purity of mogroside V obtained is 97.0%.

Embodiment 4

[0030] Example 4—The mobile phase is methanol and water, the gradient range is 2:8 to 4:6, the control flow rate is 100ml / min, and the elution time is 50min; after that, the gradient of the above-mentioned organic solvent aqueous solution is adjusted to 9:1, The elution was continued until 60 min, and the rest of the process was the same as in Example 2, and the purity of the obtained mogroside V was 97.5%.

Embodiment 5

[0031] Example 5—The mobile phase is acetonitrile and water, the gradient range is 2:8 to 3:7, the flow rate is controlled at 100ml / min, and the elution time is 30min; after that, the gradient of the above-mentioned organic solvent aqueous solution is adjusted to 5:5, The elution was continued until 60 min, and the remaining processes were the same as in Example 2, and the purity of the obtained mogroside V was 98.1%.

[0032] It can be seen from the introductions of the above examples that, through the preparation method of the present invention, the crude mogroside V after crude extraction can be directly used to prepare mogroside V without a large number of complicated and tedious pre-treatment and post-treatment processes, and the solvent used is cheap, safe and easy to separate The purification process can be monitored online in real time, which greatly improves safety and saves costs, and is suitable for large-scale industrial production. The final measurement by high pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com