Thermoplastic low-smoke halogen-free high-flame-retardant material for automobile wire and preparation method of material

A thermoplastic and automotive wire technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of high cost and expensive equipment, and achieve the effects of good oil resistance, wear resistance, easy operation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Compared with the existing preparation process, the above preparation process has simple steps and easy operation.

[0065] On the basis of the above-mentioned thermoplastic low-smoke, halogen-free, high-flame-retardant material and its preparation method, a thermoplastic low-smoke, halogen-free, and high-flame-retardant material with excellent oil resistance, high flame-retardant performance and low cost can be obtained.

[0066] Therefore, the automotive wire made of the thermoplastic low-smoke, halogen-free, and highly flame-retardant material will have the characteristics of oil resistance, high flame-retardant performance, and low cost, effectively solving the defects of existing automotive wires.

[0067] With regard to the above-mentioned embodiments, unless otherwise specified, various raw materials of the present invention can be obtained commercially; or prepared according to conventional methods in the art. Unless otherwise defined or stated, all professional...

Embodiment 1

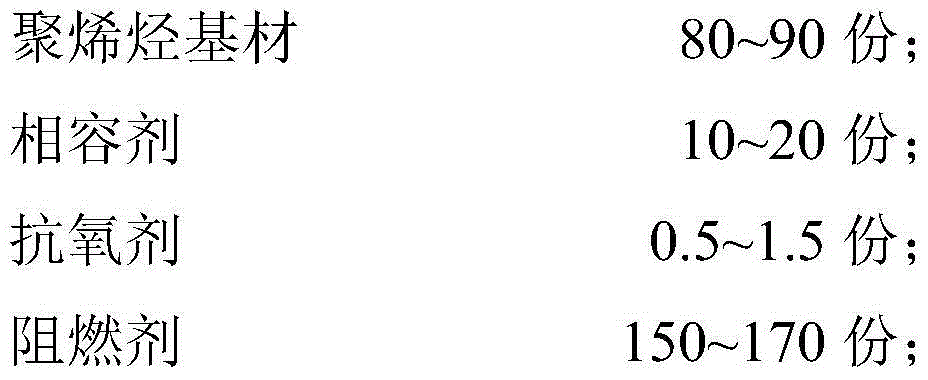

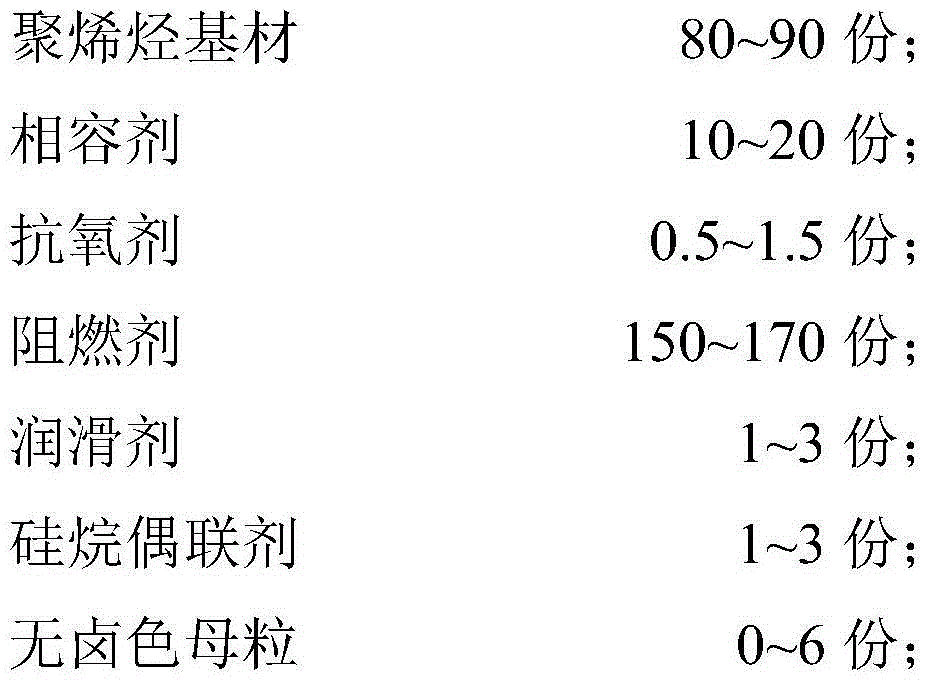

[0071] This embodiment provides a thermoplastic low-smoke, halogen-free and highly flame-retardant material for automobile wires. The raw materials and parts by weight used are as follows:

[0072]

[0073]

[0074] For the thermoplastic low-smoke, halogen-free and highly flame-retardant material in this example, its specific preparation method is as follows:

[0075] Add the polyolefin substrate, compatibilizer, antioxidant, silane coupling agent, flame retardant, lubricant, halogen-free masterbatch and other raw materials mentioned above in this example into the high-precision loss-in-weight feeding system according to the ratio The twin-screw extruder is mixed and extruded, and then conveyed to the single-screw extruder for extrusion granulation. Among them, air-cooled granulation and blast drying are carried out, and then weighed and packaged.

[0076] In this configuration method, the four temperature sections in the mixing extrusion granulation process are: feedin...

Embodiment 2

[0078] This embodiment provides a thermoplastic low-smoke, halogen-free and highly flame-retardant material for automobile wires. The raw materials and parts by weight used are as follows:

[0079]

[0080] The preparation method of the above-mentioned thermoplastic low-smoke, halogen-free and highly flame-retardant material is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com