Wear-resistant oil-proof butyronitrile patch glove and preparation method thereof

An oil nitrile and glove technology, which is applied in the field of wear-resistant and oil-proof nitrile patch gloves and the preparation thereof, can solve the problems of being difficult to meet operational needs, difficult to be applied in the market, and short in service life, and can be widely used in the market. Prospects, shortened vulcanization time, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A wear-resistant and oil-resistant nitrile patch glove comprises glove blank, glove latex and carboxylated nitrile patch.

[0033] The glove blank is a cotton glove.

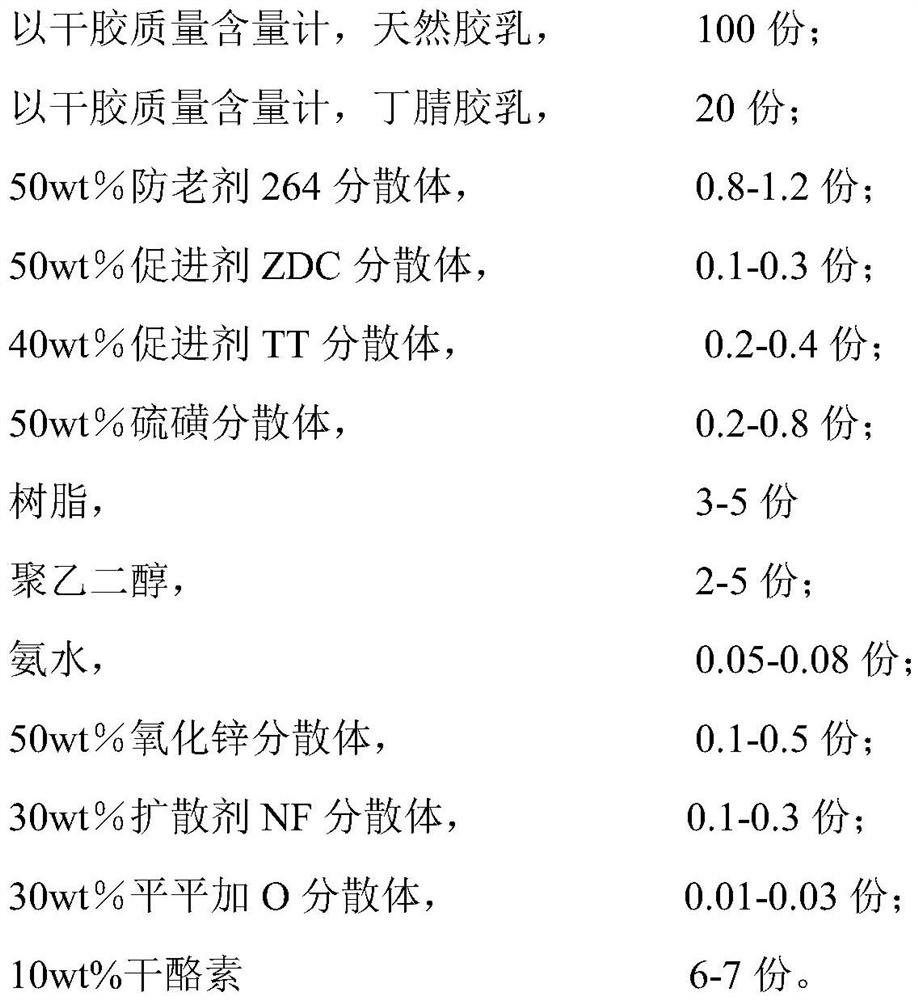

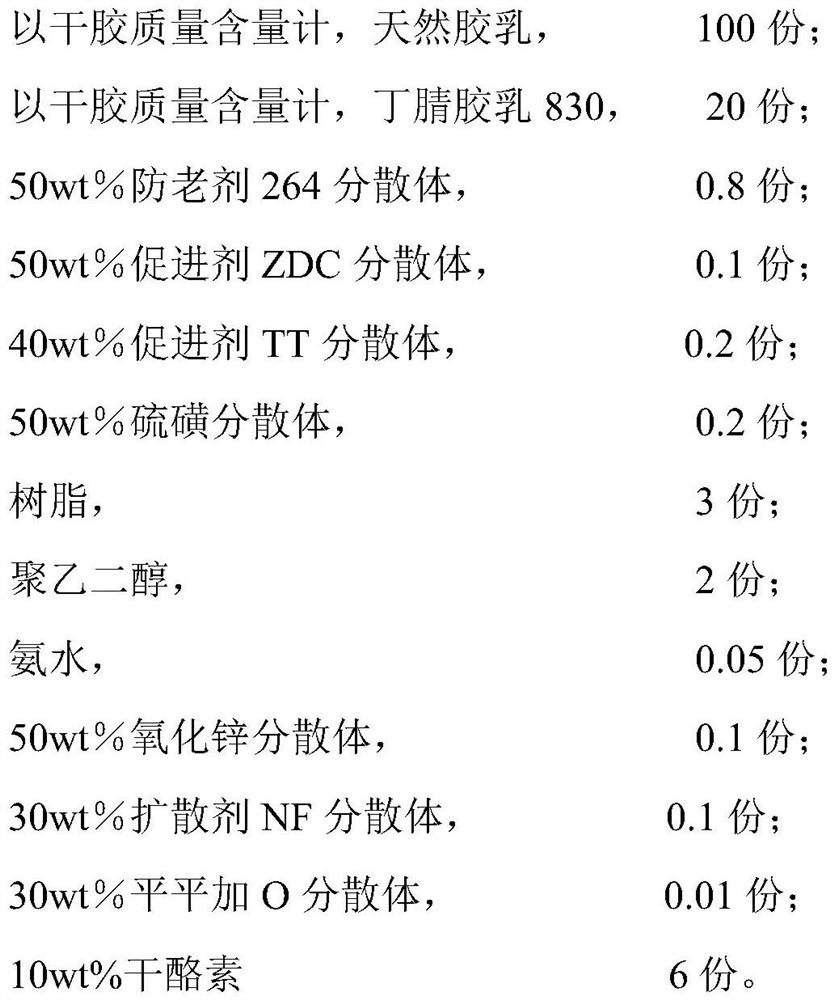

[0034] The glove latex is prepared from the following raw materials: natural rubber latex, nitrile latex, anti-aging agent 264, accelerator ZDC, accelerator TT, sulfur, resin, polyethylene glycol, ammonia water, zinc oxide, diffusing agent NF, flat plus O and casein; wherein zinc oxide is used after being prepared as 50wt% zinc oxide dispersion; sulfur is used after being prepared as 50wt% sulfur dispersion; accelerator ZDC is used after being prepared as 50wt% accelerator ZDC dispersion; accelerator TT is prepared as 40wt % Accelerator TT dispersion is used; anti-aging agent 264 is used after being configured as 50wt% anti-aging agent 264 dispersion; diffusing agent NF is used after being prepared as 30wt% diffusing agent NF dispersion; Pingping plus O is configured as 30wt% Pingping plus O dispersion U...

Embodiment 2

[0049] A wear-resistant and oil-resistant nitrile patch glove comprises glove blank, glove latex and carboxylated nitrile patch.

[0050] The glove blank is a cotton glove.

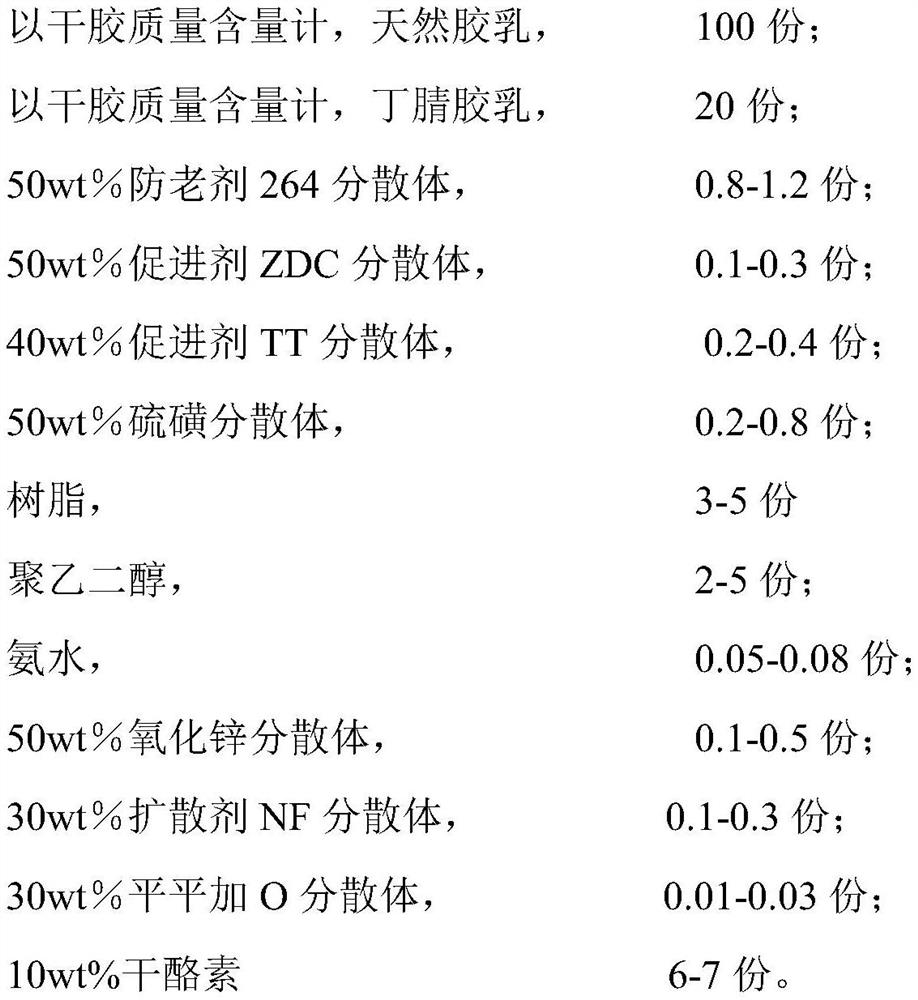

[0051] The glove latex is prepared from the following raw materials: natural rubber latex, nitrile latex, anti-aging agent 264, accelerator ZDC, accelerator TT, sulfur, resin, polyethylene glycol, ammonia water, zinc oxide, diffusing agent NF, flat plus O and casein; wherein zinc oxide is used after being prepared as 50wt% zinc oxide dispersion; sulfur is used after being prepared as 50wt% sulfur dispersion; accelerator ZDC is used after being prepared as 50wt% accelerator ZDC dispersion; accelerator TT is prepared as 40wt % Accelerator TT dispersion is used; anti-aging agent 264 is used after being configured as 50wt% anti-aging agent 264 dispersion; diffusing agent NF is used after being prepared as 30wt% diffusing agent NF dispersion; Pingping plus O is configured as 30wt% Pingping plus O dispersion U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com