Guanidine gum fracturing fluid system

A guar gum fracturing fluid and system technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of high fracturing fluid residue content, incomplete gel breaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

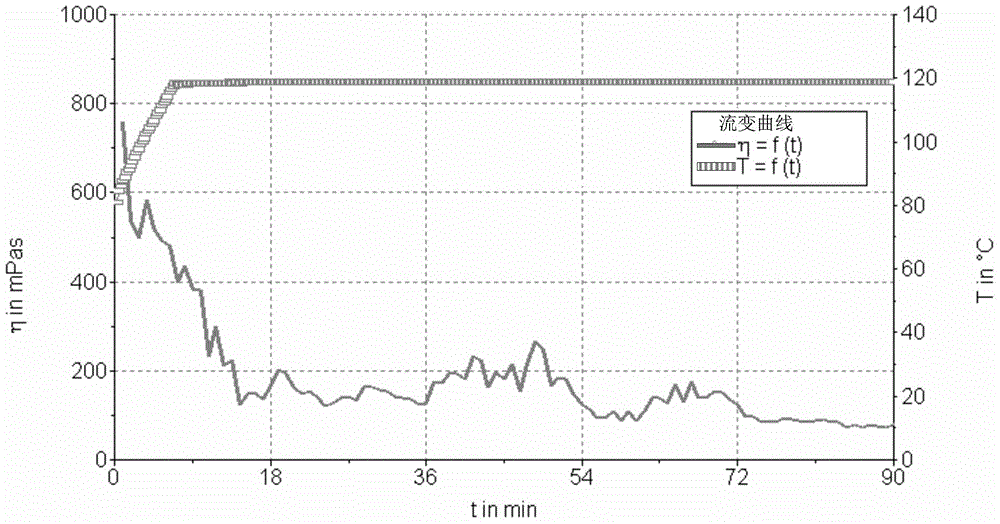

[0031] The guar gum fracturing fluid system was used for fracturing operations in sandstone reservoirs with low porosity and low permeability and a well temperature of 120°C.

[0032] Modified guar gum thickener 0.2% and water 99.6% are formulated into fracturing fluid base fluid. Modified guar gum thickener is carboxymethyl modified guar gum with special surface treatment. The appearance is light yellow powder, which belongs to The first-class product stipulated in the industry standard "SY / T5764-2007 General Technical Requirements for Vegetable Glue for Fracturing".

[0033] After it is fully swollen, add in order:

[0034] High-efficiency drainage aid 0.15%, high-efficiency drainage aid is made of perfluorooctyl carboxylic acid polyoxyethylene ether, alkylphenol polyoxyethylene ether, methanol or ethanol; 0.2% addition (mass ratio), 30°C Under these conditions, the surface tension is less than or equal to 25.0mN / m, and the interfacial tension is less than or equal to 2.0mN...

example 2

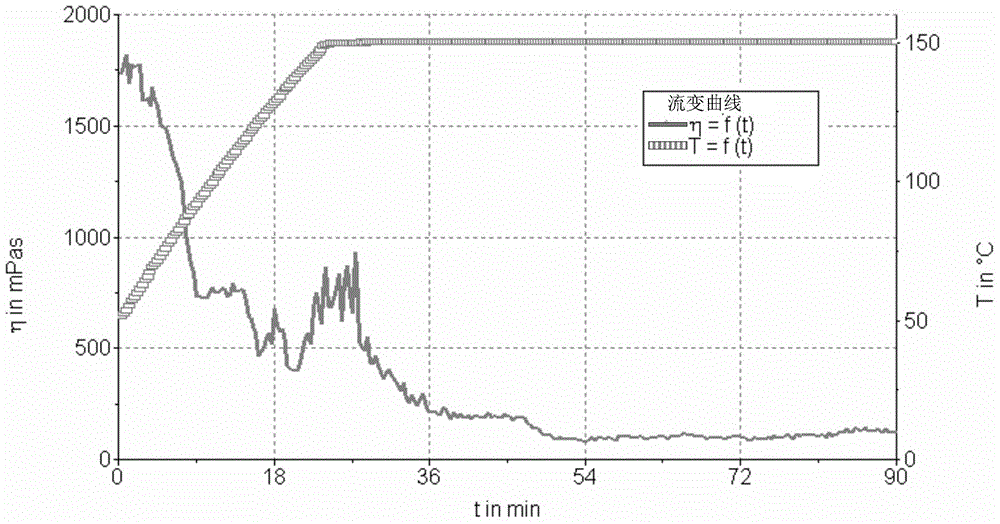

[0040] The guar gum fracturing fluid system was used for fracturing operations in sandstone reservoirs with low porosity and low permeability and a well temperature of 150°C.

[0041] Modified guar gum thickener 0.35% and water 99.52% are formulated into fracturing fluid base fluid. Modified guar gum thickener is carboxymethyl modified guar gum after special surface treatment. The appearance is light yellow powder. It is a first-class product specified in the industry standard "SY / T5764-2007 General Technical Requirements for Vegetable Glue for Fracturing".

[0042] After it is fully swollen for 12 minutes, add in sequence:

[0043] The high-efficiency drainage aid is 0.2%. The high-efficiency drainage aid is a compound of perfluorooctyl carboxylic acid polyoxyethylene ether, alkylphenol polyoxyethylene ether, methanol or ethanol. 0.2% addition (mass ratio), at 30°C, surface tension ≤ 25.0mN / m, interfacial tension ≤ 2.0mN / m.

[0044] High-efficiency clay stabilizer 0.2%, hig...

example 3

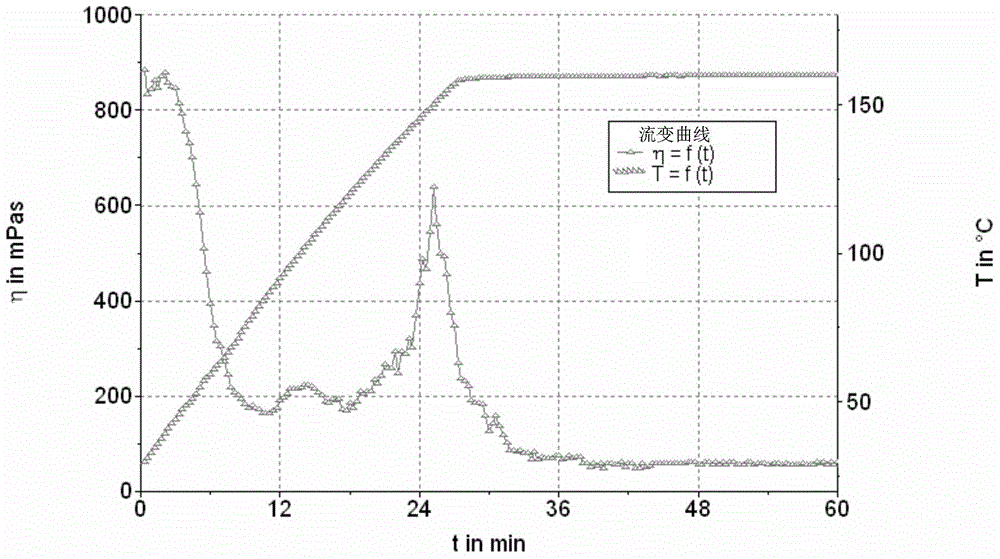

[0048] The concentrated guar gum fracturing fluid system was used for fracturing operations in sandstone reservoirs with low porosity and low permeability and a well temperature of 160°C.

[0049] 0.45% modified guar gum thickener and 99.5% water are configured as fracturing fluid base fluid. The modified guar gum thickener is carboxymethyl modified guar gum after special surface treatment. The appearance is light yellow powder, which belongs to The first-class product stipulated in the industry standard "SY / T5764-2007 General Technical Requirements for Vegetable Glue for Fracturing".

[0050] After it is fully swollen for 12 minutes, add in sequence:

[0051] The high-efficiency drainage aid is 0.2%. The high-efficiency drainage aid is a compound of perfluorooctyl carboxylic acid polyoxyethylene ether, alkylphenol polyoxyethylene ether, methanol or ethanol. 0.2% addition (mass ratio), at 30°C, surface tension ≤ 25.0mN / m, interfacial tension ≤ 2.0mN / m.

[0052] High-efficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com