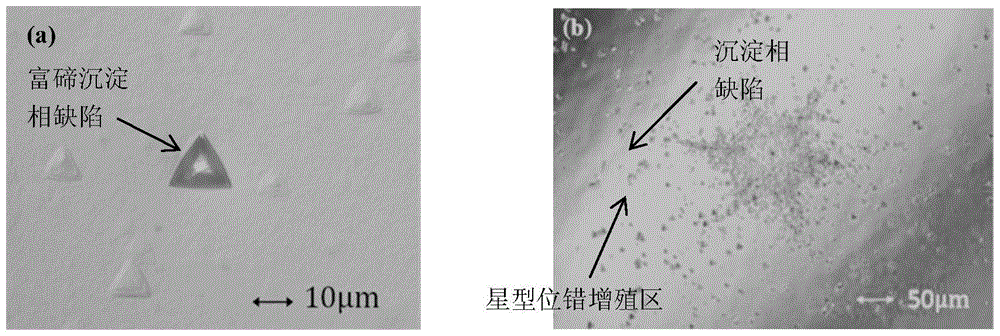

Two-step heat treatment method for eliminating defects in tellurium-rich precipitated phases in CdZnTe materials

A heat treatment method and precipitation phase technology, applied in the field of cadmium zinc telluride material manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

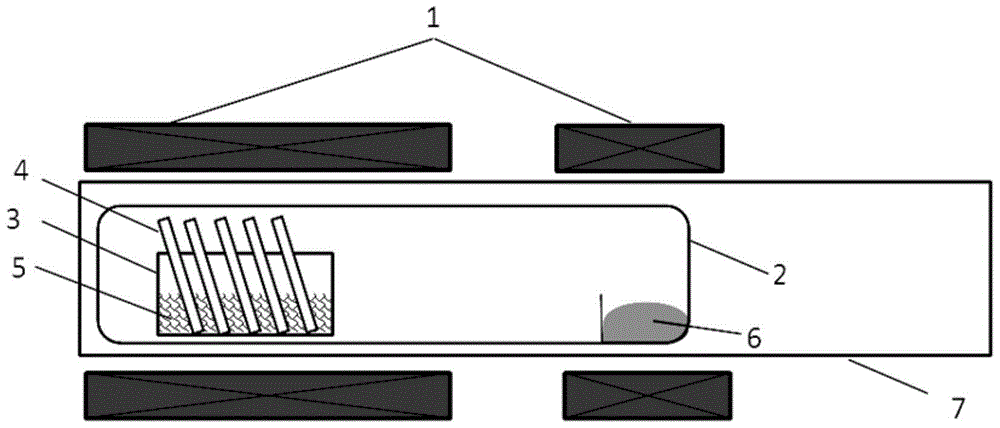

Method used

Image

Examples

Embodiment Construction

[0027] 1. Preparation of materials for heat treatment

[0028] 1) Use an infrared transmission microscope to detect the treated cadmium zinc telluride material, and classify it according to the type of precipitated phase defects contained in the material (tellurium-rich and cadmium-rich precipitated phase defects) and size, and the precipitated phase should be selected for each heat treatment process Samples with approximately the same defect size, and the samples are cleaned as follows;

[0029] a) Put the sample into the trichlorethylene melt and heat it to boiling, take the sample out of the melt, replace the trichlorethylene melt and then heat it to boiling, for 3 or more times in a row, take it out and put it into methanol melt Wash in liquid for 3 or more times;

[0030] b) Configure Br methanol melt (concentration is 0.5% ~ 1%), put the sample into Br methanol melt and corrode for 10 seconds or more, take it out quickly and put it into methanol melt to wash 3 times or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com