Manufacturing method and coating of glass fiber fire blanket

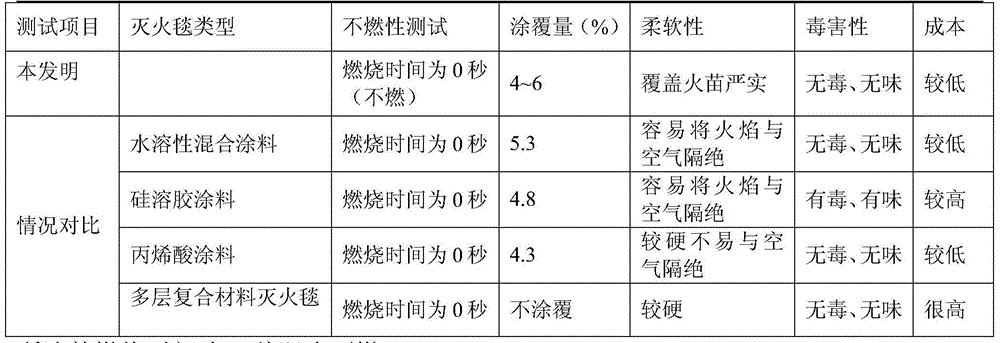

A glass fiber and fire blanket technology, applied in fiber treatment, coating, fire rescue, etc., can solve the problems of high cost, poor wear resistance, harmful substances in solvents, etc., and achieve the effect of avoiding damage and preventing the spread of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a manufacturing method of a glass fiber fire extinguishing blanket and coating thereof, the described fire extinguishing blanket is a square, and the specific manufacturing process is:

[0027] Step 1, prepare the paint: Prepare the paint according to the process formula for preparing the paint for coating.

[0028] Preparation of coating process formula:

[0029] Material

PTFE

Silica sol

softener

flame retardant

Dosage

12.5wt%

10.5wt%

9.5wt%

2.5wt%

65.0Wt%

[0030] The solid content of described polytetrafluoroethylene emulsion is 60Wt%, silica sol (SiO 2 .nH 2 O) The solids content of the emulsion is 40 wt%. The softener is YG-303 imidazoline lubricant produced by Xi'an Organic Composite Materials Co., Ltd., and the flame retardant is powdered PA6 halogen-free flame retardant.

[0031] Mix the polytetrafluoroethylene, silica sol, softener and flame retardant by conventiona...

Embodiment 2

[0041] The present embodiment is a manufacturing method of a glass fiber fire extinguishing blanket and a coating thereof. The described fire extinguishing blanket is rectangular, and the specific manufacturing process is as follows:

[0042] Step 1, prepare the paint: Prepare the paint according to the process formula for preparing the paint for coating.

[0043] Preparation of coating process formula:

[0044] Material

PTFE

Silica sol

softener

flame retardant

Dosage

14.5Wt%

9.5wt%

8.5wt%

2.0Wt%

65.5Wt%

[0045] The solid content of described polytetrafluoroethylene emulsion is 60Wt%, silica sol (SiO 2 .nH 2 O) The solids content of the emulsion is 40 wt%. The softener is YG-303 imidazoline lubricant produced by Xi'an Organic Composite Materials Co., Ltd., and the flame retardant is powdered PA6 halogen-free flame retardant.

[0046] Mix the polytetrafluoroethylene, silica sol, softening agent and f...

Embodiment 3

[0056] The present embodiment is a manufacturing method of a glass fiber fire extinguishing blanket and a coating thereof. The described fire extinguishing blanket is rectangular, and the specific manufacturing process is as follows:

[0057] Step 1, prepare the paint: Prepare the paint according to the process formula for preparing the paint for coating.

[0058] Preparation of coating process formula:

[0059] Material

PTFE

Silica sol

softener

flame retardant

Dosage

10.5wt%

12.0Wt%

11.0Wt%

3.0Wt%

63.5Wt%

[0060] The solid content of described polytetrafluoroethylene emulsion is 60Wt%, silica sol (SiO 2 .nH 2 O) The solids content of the emulsion is 40 wt%. The softener is YG-303 imidazoline lubricant and GY-303 softener produced by Xi'an Organic Composite Materials Co., Ltd., and the flame retardant is powdered PA6 halogen-free flame retardant.

[0061] Mix the polytetrafluoroethylene, silica sol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com