Deep see immersed type tunnel based on rigidity carrier

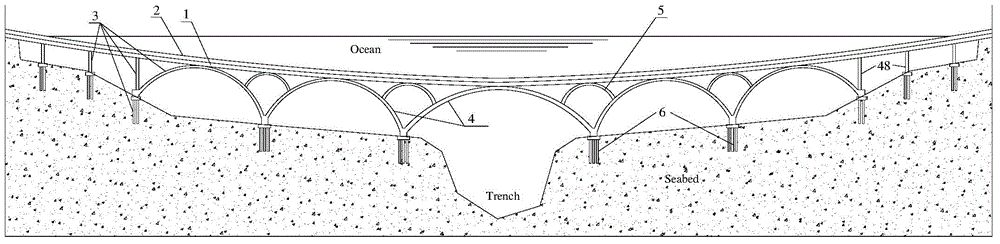

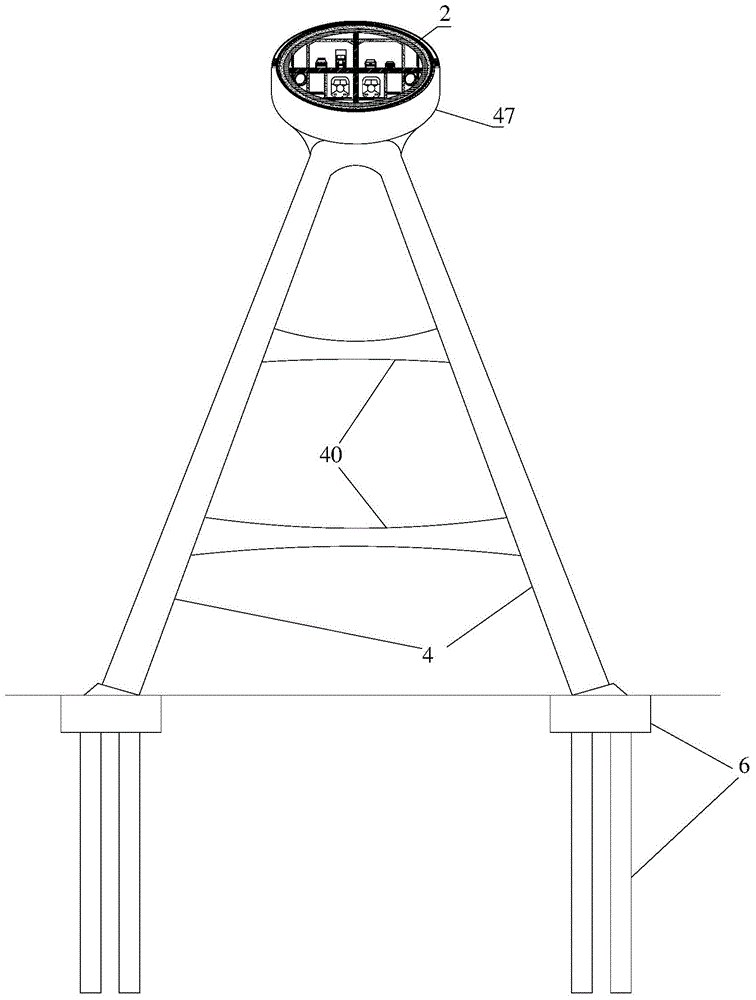

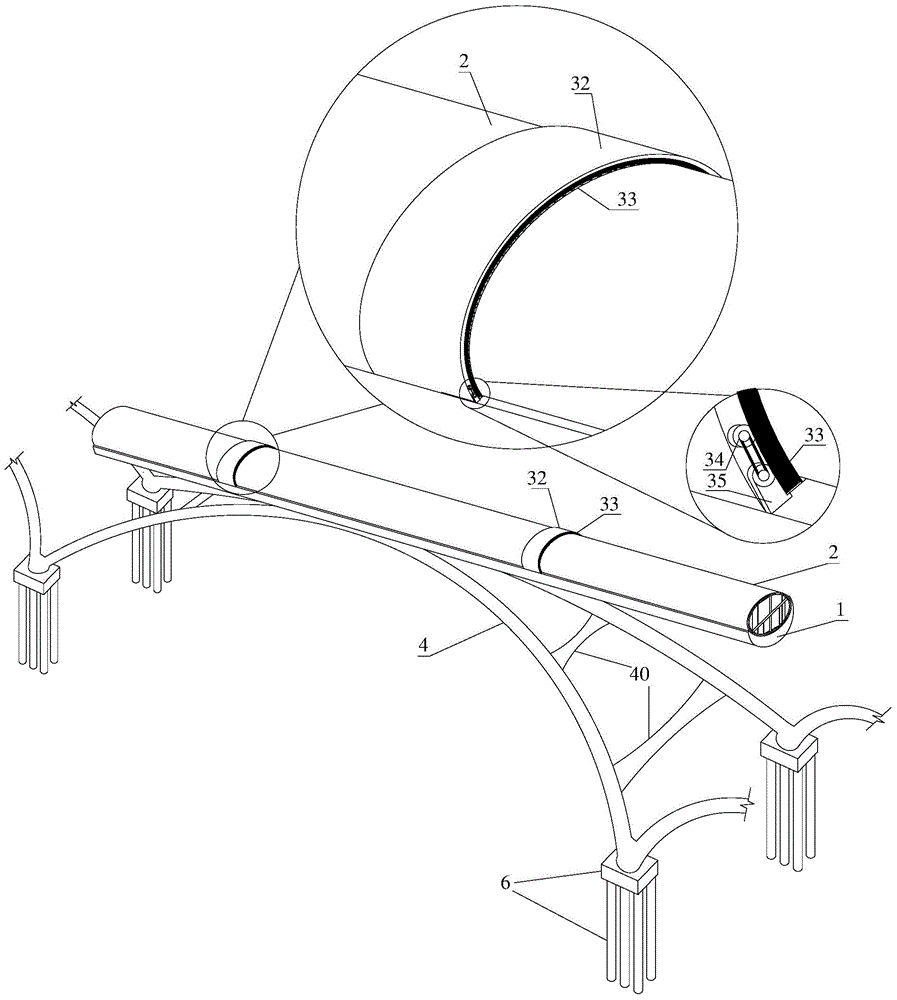

A submersible and carrier-based technology, applied in the field of deep-sea submersible tunnels based on rigid carriers, can solve the problems of no unified combination design for tunnel functional areas, escape areas and escape areas, large deformation of tunnels, and large flexibility, so as to improve the resistance to ocean currents Action capacity and spanning capacity, increased stiffness, effects of increased longitudinal and transverse stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described;

[0066] A construction method based on the rigid carrier deep-sea submersible tunnel using the above-mentioned design, the specific steps are as follows:

[0067] Step 1: Project preparation, prefabrication of materials and components and construction of lightering wharf in the shore factory, large-scale lightering equipment and underwater construction equipment entering the factory for debugging.

[0068] Step 2: Construction of the foundation 6 of the support structure 3, using an engineering ship to carry out underwater piling construction and underwater pouring of pile foundations and caps;

[0069] Step 3: Construction of the upper structure of the support structure 3, the prefabricated components on the shore are carried out underwater prefabricated and assembled by the engineering ship and the engineering submarine through the cooperation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com