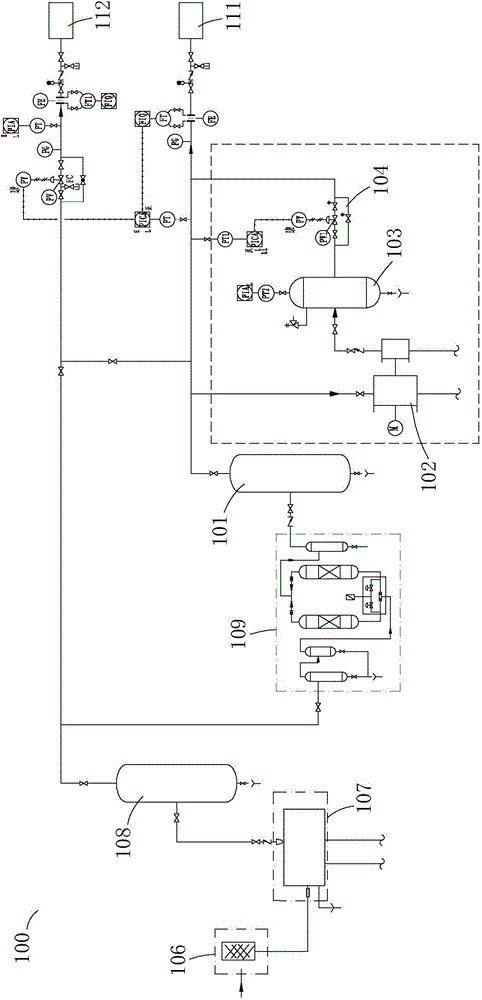

Storage and emergency supply device and method for standby instrument gas source

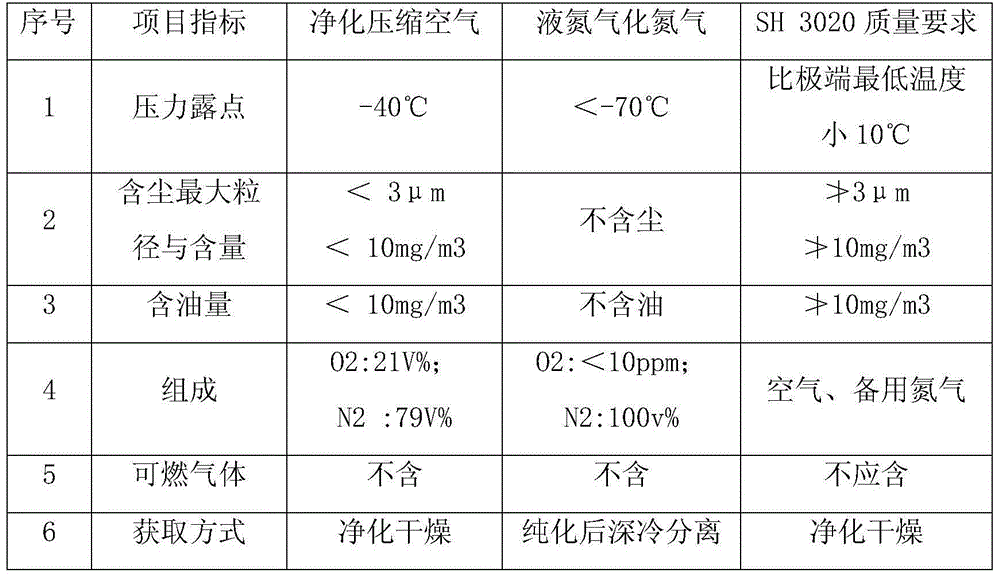

A technology of backup instrument and supply device, which is applied in the field of storage and emergency supply device for providing backup instrument gas source, can solve the problems of many supporting facilities, high pressure of medium-pressure purified compressed air storage tank 103, consumption of water and electricity, etc. Avoid material consumption, reduce equipment investment, and reduce the effect of supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

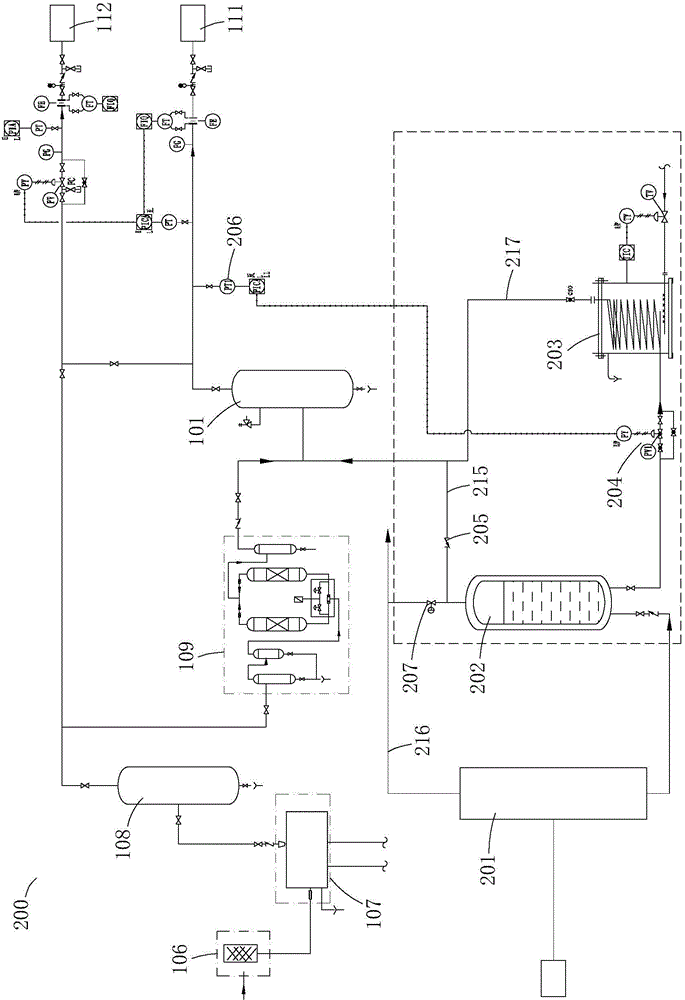

[0039] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0040] see figure 2 As shown, it is a schematic structural diagram of the storage and emergency supply device of the standby instrument gas source of the present invention, a storage and gasification equipment, including a liquid nitrogen storage tank 202 connected in series through pipelines, a control valve group 204 and a gasifier 203; storage and gasification equipment such as figure 2 shown in the dotted box. The liquid nitrogen in the liquid nitrogen storage tank 202 is input into the gasifier 203 through the opened control valve group 204, and the gasifier 203 has an output port.

[0041] The invention adopts liquid nitrogen as the storage mode of the backup instrument gas so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com