Fault detection circuit and method for self-checking of frequency mixer

A technology of fault detection circuit and mixer, which is applied in the direction of measuring electricity, measuring electrical variables, instruments, etc., can solve the problems of no inspection circuit, no self-inspection, and affecting equipment maintenance time, so as to improve detection efficiency and reduce detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

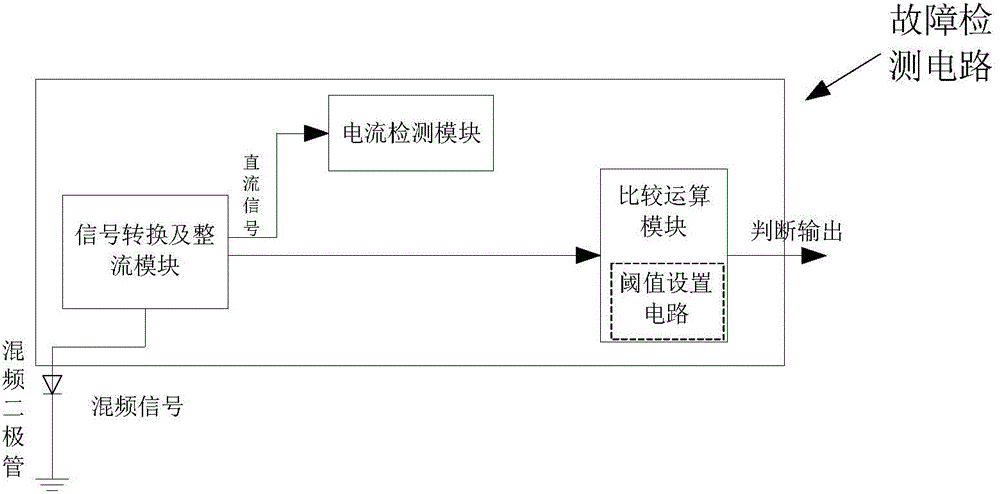

[0024] The concrete realization principle of the present invention is as figure 1 Shown:

[0025] The present invention is a fault detection circuit for mixer self-test, which is mainly composed of three parts: a signal conversion and rectification module, a current detection module and a comparison operation module, wherein the comparison operation module includes a threshold value setting circuit. The signal conversion and rectification module introduces the frequency mixing diode into the circuit, and is mainly responsible for converting the input signal into a DC signal. The current detection module is mainly responsible for detecting the size of the DC signal, and the comparison operation module is mainly responsible for checking the size and presence of the converted DC signal. To judge, the threshold setting circuit can set the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com