Method for preparing canned hawthorn

The technology of hawthorn and canned food is applied in the field of preparation of canned hawthorn, can solve the problems of shortening, the hardness and fragrance of pulp are not easy to maintain, and the heat treatment time is reduced, and the effects of reducing damage, simple and feasible preparation method, and reducing heat treatment time and temperature are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of canned hawthorn, which comprises the steps of:

[0018] Step 1) Pretreatment: select pure, fresh, moderately mature and complete hawthorn as raw materials; then undergo peeling, stem removal and stone removal in order to obtain raw material A;

[0019] Step 2) Water treatment: Soak the raw material A obtained in step 1) in deionized water at 5°C for 3 minutes, and then take it out for later use, which is raw material B;

[0020] Step 3) Enzyme inactivation: Put the raw material B obtained in step 2) in 0.1% (w / w) citric acid aqueous solution for enzymatic inactivation treatment, the temperature is 40°C, the vacuum degree is 0.06Mpa, the time is 5min, take it out for later use, That is raw material C;

[0021] Step 4) Preparation of material liquid A: Boil deionized water in a pot, then add fructose syrup and vitamin C into the boiling water and stir for 3 minutes, then cool naturally; among them, deionized water, fructose syrup and vitamin C Th...

Embodiment 2

[0025] A preparation method of canned hawthorn, which comprises the steps of:

[0026] Step 1) Pretreatment: select pure, fresh, moderately mature and complete hawthorn as raw materials; then undergo peeling, stem removal and stone removal in order to obtain raw material A;

[0027] Step 2) Water treatment: Soak raw material A obtained in step 1) in deionized water at 10°C for 5 minutes, then take it out for later use, which is raw material B;

[0028] Step 3) Enzyme inactivation: Place the raw material B obtained in step 2) in 0.1% (w / w) citric acid aqueous solution for enzymatic inactivation treatment, the temperature is 50°C, the vacuum degree is 0.08Mpa, and the time is 6min. That is raw material C;

[0029] Step 4) Preparation of material liquid A: Boil deionized water in a pot, then add fructose syrup and vitamin C into the boiling water and stir for 3 minutes, then cool naturally; among them, deionized water, fructose syrup and vitamin C The mass ratio of C is 100:3:1...

Embodiment 3

[0033] The invention uses the new technology of temperature control and negative pressure technology to produce canned hawthorn, which reduces a precooking process, further simplifies the production process, and effectively solves the problems of large amount of labor and high production cost in the current production of canned hawthorn. Compared with the traditional process, this technology produces 1 ton of products, the cost is reduced by more than 15%, the production efficiency is increased by more than 40%, and the labor cost is reduced by more than 30%; the heating time is shortened by more than half, and the steam consumption is greatly reduced. The bad cooking taste and the loss of fructose caused by the process of producing canned hawthorn have brought huge profits while improving the quality.

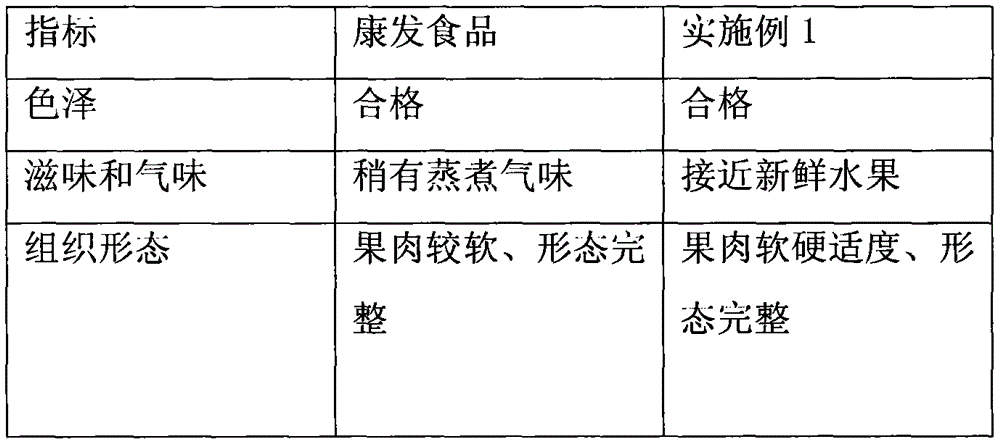

[0034] The comparison between the present invention and similar products is shown in Table 1:

[0035] Table 1

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com