Vibration material grinding device used for powder

A technology of vibrating mills and powders, which is applied in the direction of making medicines into special physical or ingestible devices, etc., which can solve the problems of poor abrasive effect and achieve good abrasive effect, good crushing effect, and increased relative motion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

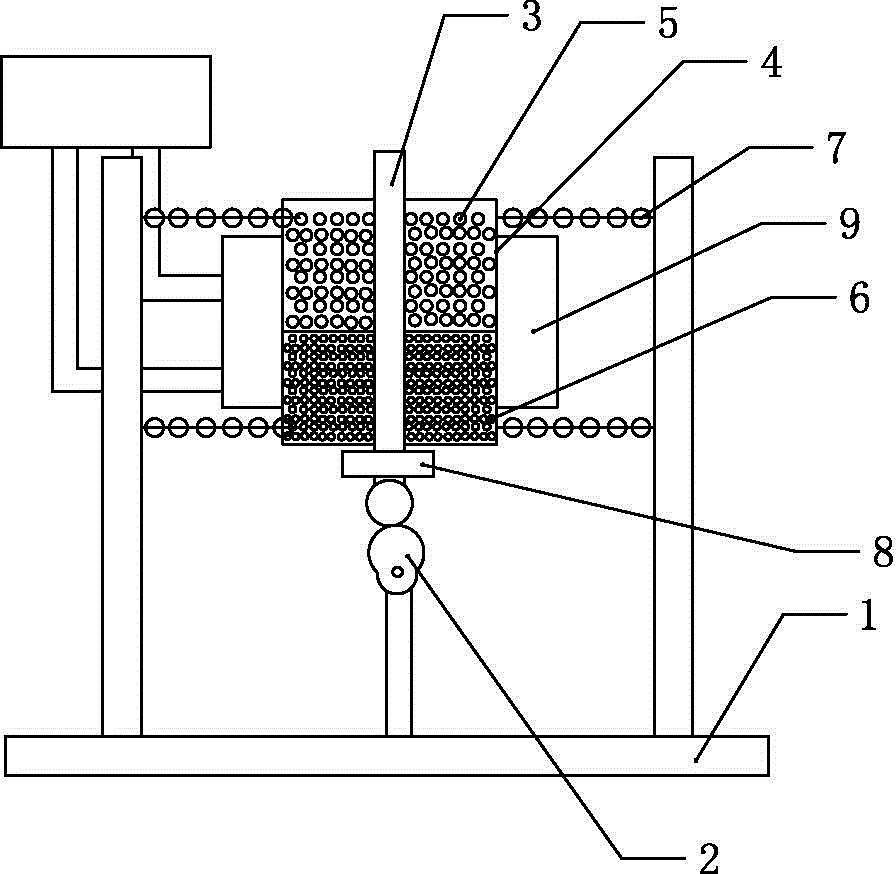

[0012] Among the figure: base 1, cam 2, main shaft 3, abrasive cylinder 4, upper abrasive ball 5, lower abrasive ball 6, spring 7, buffer sleeve 8, water bath cylinder 9.

[0013] Such as figure 1 As shown, the vibrating abrasive device for powder of the present invention includes a base 1, a cam 2, a main shaft 3 and an abrasive barrel 4, the center of the base 1 is provided with a support rod, and both sides of the base 1 are provided with vertical supports , the cam 2 is rotatably connected with the upper end of the support rod, the abrasive cylinder 4 is located above the cam 2, the main shaft 3 passes through the abrasive cylinder 4 and is offset against the cam 2, and the main shaft 3 is located below the abrasive cylinder 4 and is provided with a buffer sleeve 8, the buffer sleeve Cylinder 8 just adopts rubber cylinder, and the inner wall of rubber cylinder is provided with foam cushion layer, and abrasive material cylinder 4 is divided into upper part and lower part, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com