Ultrasonic device for cleaning denitration catalyst

A technology for denitrification catalysts and out-of-stock catalysts, which is applied in the field of ultrasonic devices for cleaning denitrification catalysts. It can solve the problems of uncleaning, attenuation, and low regeneration quality in the central area, and achieve good regeneration quality, good cleaning effect, and uniform energy distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

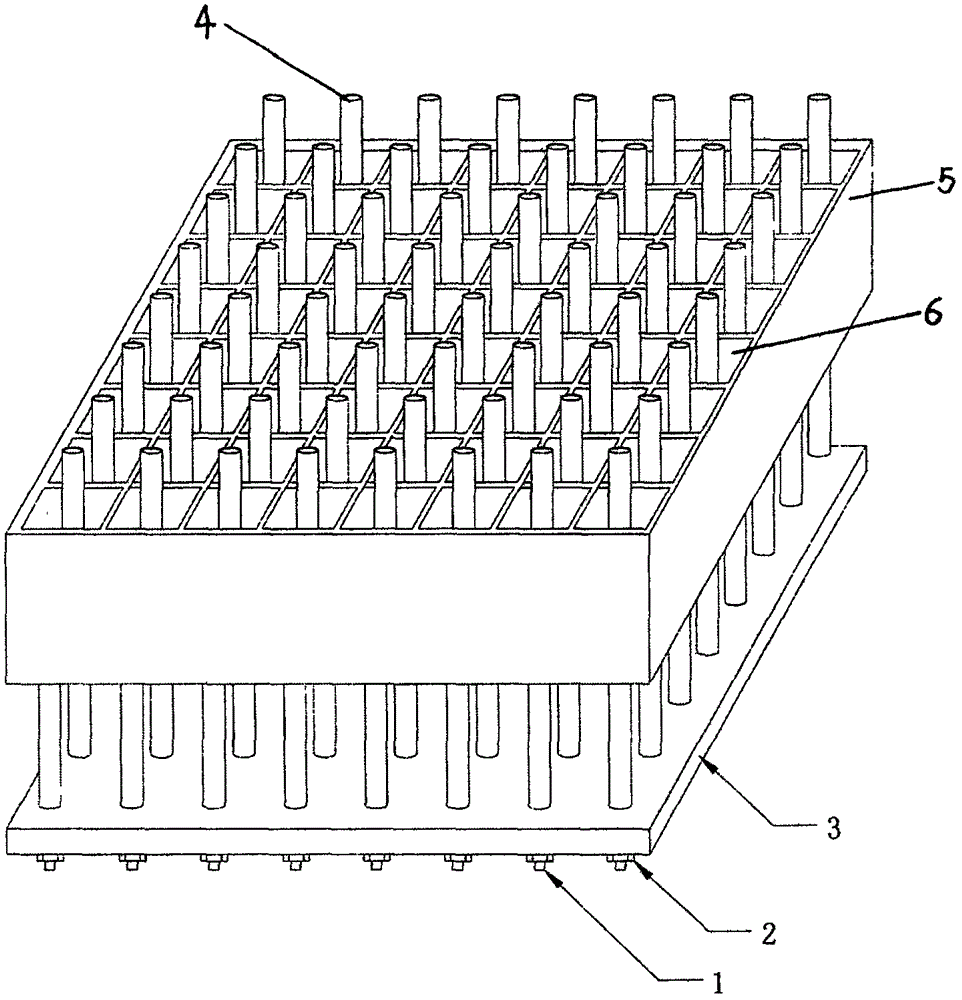

[0016] Such as figure 1 The ultrasonic device for cleaning the denitration catalyst shown includes an ultrasonic generator 1 , an ultrasonic rod 4 and a porous flange 3 . The ultrasonic generator 1 is connected to the ultrasonic rod 4, and the ultrasonic rod 4 is one or more than one. The ultrasonic rods 4 are arranged in parallel, and the gap between the ultrasonic rod 4 and the hole 6 is matched. One end of the rod 4 is connected with the porous flange 3 through the fixing nut 2, and the ultrasonic rod 4 can be made of titanium alloy or rare earth titanium alloy or stainless steel or aluminum alloy.

[0017] When in use, take an invalid denitrification catalyst module, put it into the ultrasonic cleaning device after vacuuming with negative pressure, insert the ultrasonic rod into the hole of the denitrification catalyst to clean the inside of the denitrification catalyst, and the ultrasonic generator emits ultrasonic waves (the frequency is 16KHZ-100000KHZ), the direction ...

Embodiment 2

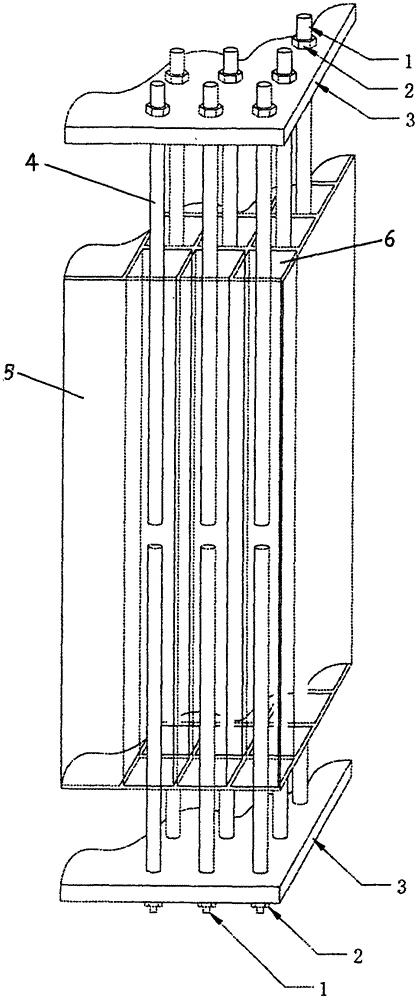

[0019] Such as figure 2 The ultrasonic device for cleaning the denitration catalyst shown includes an ultrasonic generator 1 , an ultrasonic rod 4 and a porous flange 3 . The ultrasonic generator 1 is connected to the ultrasonic rod 4, and the ultrasonic rod 4 is one or more than one. The ultrasonic rods 4 are arranged in parallel, and the gap between the ultrasonic rod 4 and the hole 6 is matched. Insert, one end of each ultrasonic rod 4 extends out of the hole of the denitration catalyst 5 and is connected with the porous flange 3 through the fixing nut 2, and the other end is in the hole 6, and the ultrasonic rod 4 can be titanium alloy or rare earth titanium alloy or stainless steel or made of aluminum alloy.

[0020] When in use, take an invalid denitrification catalyst module, put it into the ultrasonic cleaning device after vacuuming with negative pressure, insert the ultrasonic rod into the hole of the denitrification catalyst to clean the inside of the denitrificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com