Natural gas triglycol dehydrating process

A technology of natural gas and triethylene glycol, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of increased consumption of triethylene glycol, reduced dew point drop, and lower dew point of raw material gas, and achieves low operating costs, Small pressure drop, simple and reliable pipe layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

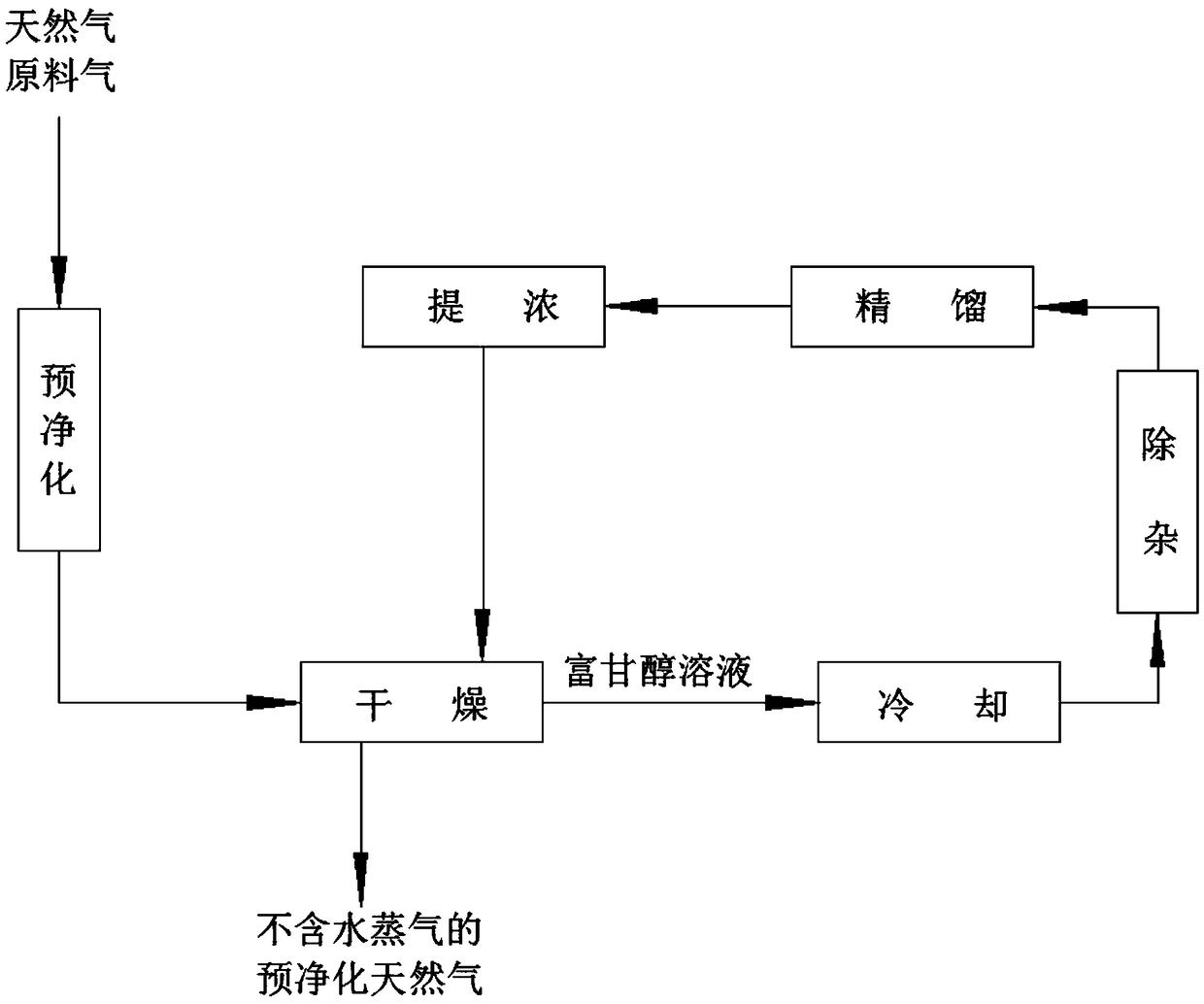

[0031] Such as figure 1 Shown, a kind of natural gas triethylene glycol dehydration process, concrete process steps are as follows:

[0032] 1) Pre-purification: natural gas raw material gas is pre-purified natural gas after the separator removes free water, liquid hydrocarbons and solid impurities;

[0033] 2) drying: the pre-purified natural gas obtained in step 1) is introduced into the bottom of the absorption tower, and made to contact with the triethylene glycol solution flowing down through each layer of trays in countercurrent, so that the water vapor in the pre-purified natural gas is absorbed by the triethylene glycol solution Absorption, forming a glycol-rich solution, which flows out from the lower side of the absorption tower, and the pre-purified natural gas without water vapor flows out from the top of the tower;

[0034] 3) Cooling: Pass step 2) the glycol-rich liquid through a gas / lean glycol heat exchanger to cool it down;

[0035] 4) Impurity removal: Step...

Embodiment 2

[0040] As shown in Example 1, other conditions remain unchanged, so that the glycol-rich solution cooled in step (4) first passes through the filter instead of the glycol pump, and directly enters the regeneration tower top reflux condenser. After being treated by this process, the dew point of the exported natural gas is below -14°C, the dehydration balance is above 96%, and the concentration of the glycol-poor concentrated solution after regeneration can reach above 97%.

Embodiment 3

[0042] As shown in Example 2, other conditions remain unchanged, so that the glycol-rich solution cooled in step (4) first passes through the glycol pump instead of the filter, and directly enters the regeneration tower top reflux condenser. After being treated by this process, the dew point of the exported natural gas is below -13°C, the dehydration balance is above 94%, and the concentration of the glycol-poor concentrated solution after regeneration can reach above 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com